Preparation method of flat lens

A flat lens and gel technology, applied in lenses, instruments, optics, etc., can solve the problems of long production cycle and difficult operation, and achieve the effect of high damage threshold, simple process and production cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

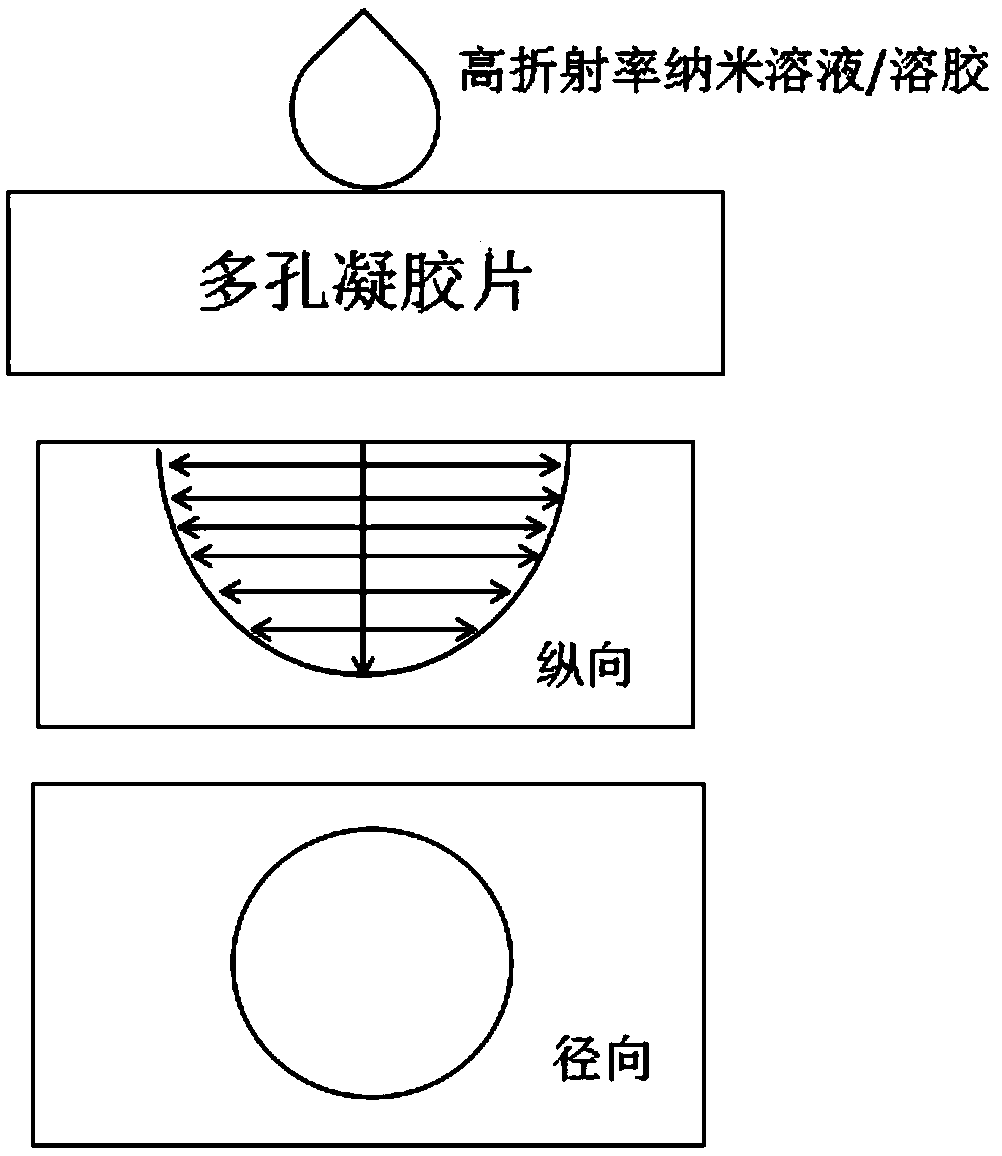

[0027] A method for preparing a planar lens, comprising the following process: adding 1 mL of a nanofluid material solution with a mass concentration of 0.1% dropwise to a surface area of 1 mm in thickness and receiving a nanofluid material of 1 cm 2 On the gel block material, the refractive index of the gel block material permeated by the nano fluid material is gradually changed through the diffusion of the nano fluid material in the gel block material, and a flat lens is formed after drying.

Embodiment 2

[0029] A preparation method of a plane lens, comprising the following process: adding 10 mL of a nanofluid material solution with a mass concentration of 1% to a thickness of 5 mm and a surface area of 10 cm for receiving the nanofluid material 2 On the gel block material, the refractive index of the gel block material permeated by the nano fluid material is gradually changed through the diffusion of the nano fluid material in the gel block material, and a flat lens is formed after drying.

Embodiment 3

[0031] A preparation method of a planar lens, comprising the following process: adding 100mL of a crystalline Si nanoparticle solution with a mass concentration of 5% to a surface area of 10mm in thickness and receiving a nanofluid material of 100cm 2 On the porous silica gel block, through the diffusion of crystalline Si nanoparticles in the porous silica gel block, the refractive index of the porous silica gel block material after the crystalline Si nanoparticle infiltration is gradually changed, and dried Finally, a plane lens is formed; the pore diameter of the porous silica gel block is 20 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com