A kind of preparation method of supporting type palladium-alumina catalyst

A catalyst, alumina technology, applied in the direction of physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, catalyst carrier, etc. Utilization, catalyst promotion effect is not optimal and other problems, to achieve good catalytic life, production process safety, improve activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

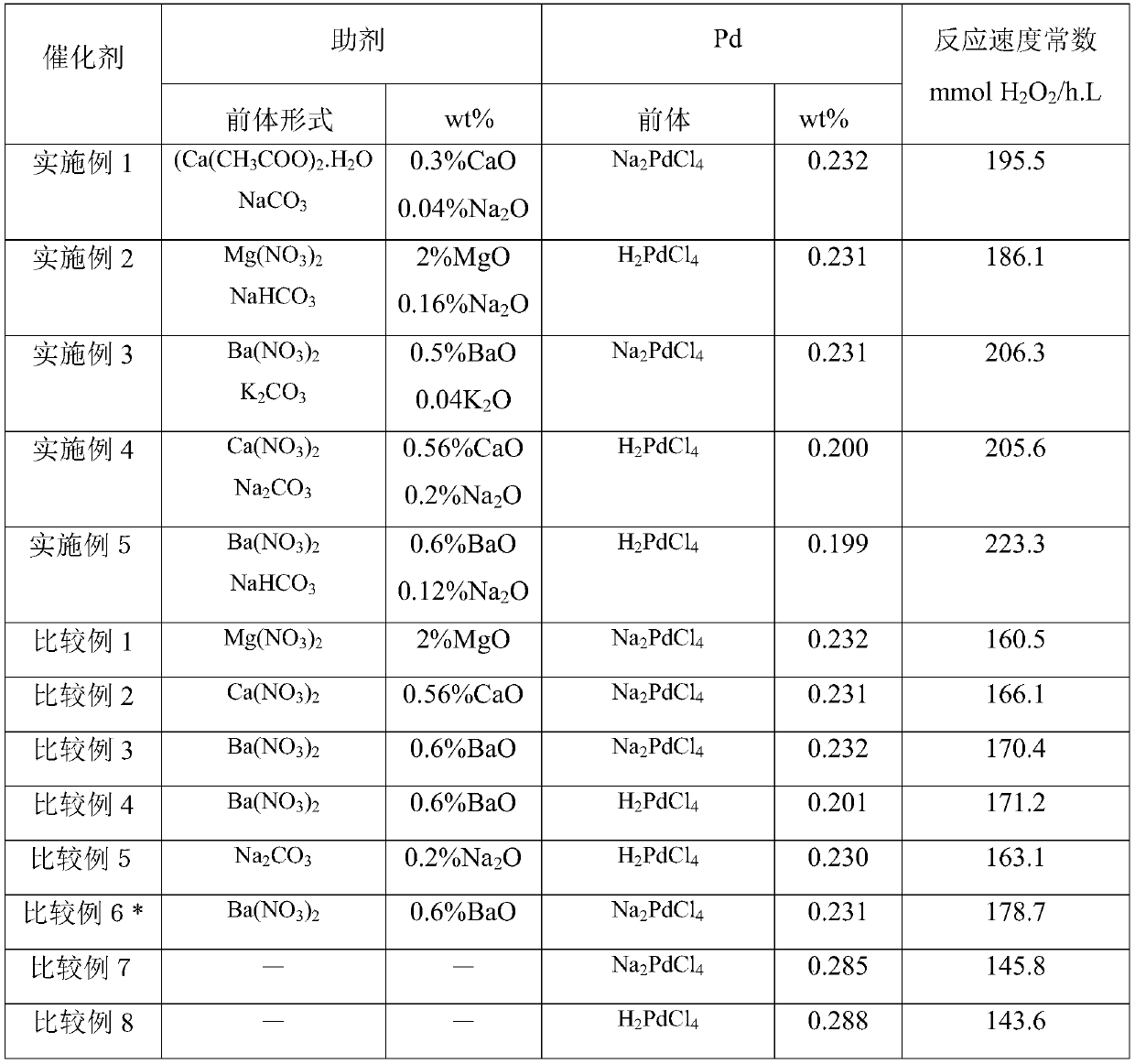

Examples

preparation example Construction

[0020] Specifically, the preparation method of the supported palladium-alumina catalyst provided by the invention includes:

[0021] preparing an aluminum sol with an Al / Cl mass ratio of 1.0 to 1.5 and an Al content of 9 to 16 wt %;

[0022] Mixing the alkaline earth metal oxide precursor salt solution, the hexamethylenetetramine solution and the aluminum sol to form a premix solution, and keeping the temperature of the premix solution at 5-10°C;

[0023] The premixed solution is granulated by the oil column forming method to obtain aluminum rubber balls;

[0024] After the aluminum rubber balls are aged and washed, they are dried at 100-120°C for 4 hours, 200-300°C for 2-3 hours, 550°C for 3-4 hours, 960-1000°C for 3-4 hours, and cooled Obtain alumina carrier;

[0025] impregnating the alumina carrier with a precursor salt solution of an alkali metal oxide and then drying;

[0026] The dried alumina carrier is impregnated with metal palladium precursor solution, washed wit...

Embodiment 1

[0043] Take by weighing 60g purity ≥ 99.0wt% metal aluminum powder and 240g deionized water add in the 1000ml three-necked flask that has glass stirrer, thermometer, reflux condenser, by aluminum chloride weight ratio Al / Cl=1.4 / 1, (w / w) to the there-necked flask to add concentration of 15wt% hydrochloric acid, the stirring speed is controlled at 1000 rev / min, and the hydrogen generated in the reaction process is exported through the upper opening of the condensing tube. In the initial stage of the reaction between metal aluminum powder and hydrochloric acid, the temperature is rapidly raised to 50°C by external heating, and then the heating is stopped, and then the temperature of the reaction system is maintained at 95-100°C due to the heat release of the aluminum hydrolysis reaction. When the temperature cannot be maintained by the heat of reaction at the later stage of the reaction, the temperature of the system is maintained in the above range by external heating. After th...

Embodiment 2

[0053] Repeat the process of embodiment 1, difference is:

[0054] Change the precursor salt of alkaline earth metal oxide to Mg(NO 3 ) 2 . That is, when adding the precursor salt solution of the alkaline earth metal oxide to the aluminum sol, the Mg(NO 3 ) 2The aqueous solution was added to the aluminum sol and stirred evenly. Based on the weight of the alumina carrier, the loading amount of MgO on the carrier is about 2wt%.

[0055] Change the precursor salt of alkali metal oxide to NaHCO 3 . That is, with 30ml of NaHCO with a concentration of 0.05163mol / L 3 The aqueous solution impregnated 30 g of the macroporous spherical alumina carrier prepared above. Based on the weight of the alumina carrier, the Na on the carrier 2 The O loading is about 0.16wt%.

[0056] Change the metal palladium precursor solution to H 2 PdCl 4 solution. That is, pour 70ml of H with a concentration of 0.00958mol / L and a temperature of room temperature 2 PdCl 4 solution for impregnati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com