Numerically-controlled grinding system for square box

A square box and grinding wheel technology, applied in the direction of grinding machine, grinding frame, grinding bed, etc., can solve the problems of poor grinding effect, low efficiency, incomplete grinding of the box body, etc., and achieve simple structure and convenient use. , excellent grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

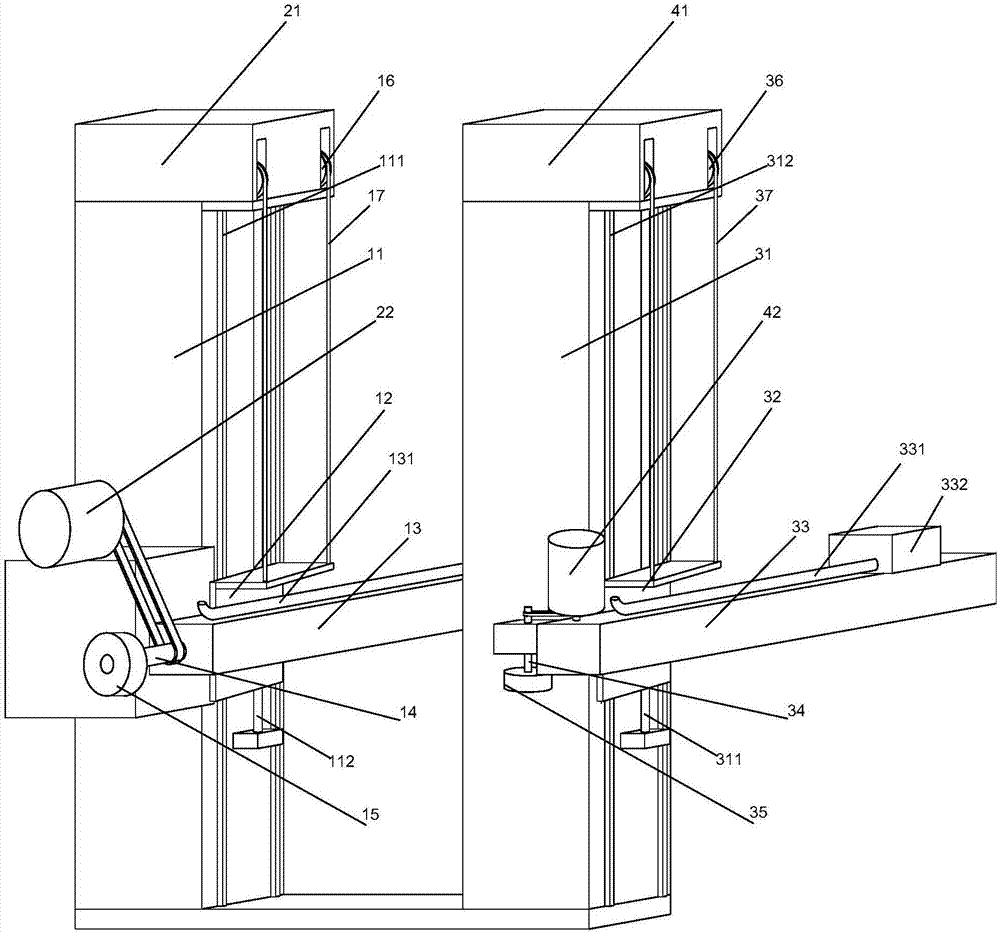

[0018] refer to figure 1 As shown, a square box CNC grinding system proposed by the present invention includes a first grinding mechanism, a first driving mechanism, a second grinding mechanism, a second driving mechanism, a control device and a laser scanning device;

[0019] The first grinding mechanism comprises a first mounting frame 11, a first sliding frame 12, a first moving frame 13, a first rotating shaft 14 and a first grinding wheel 15; Guide rail 111, the first mounting frame 11 is also equipped with a first screw rod 112, the first screw rod 112 is axially parallel to the extension direction of the first sliding guide rail 111, and the first sliding frame 12 is provided with the first screw rod 112. The first internally threaded hole, the first sliding frame 12 is connected with the first screw rod 112 through the first internally threaded hole, the first sliding frame 12 is also provided with a first chute compatible with the first sliding guide rail 111, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com