Connection joint of climbing tower crane supporting frame and wall body and implementation method

A technology for connecting nodes and implementing methods, applied in the field of climbing tower cranes, can solve the problems of stress concentration, easy deformation of the ear plate to the outside, large ear plate, etc., and achieves the effect of saving construction period, facilitating safety monitoring, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

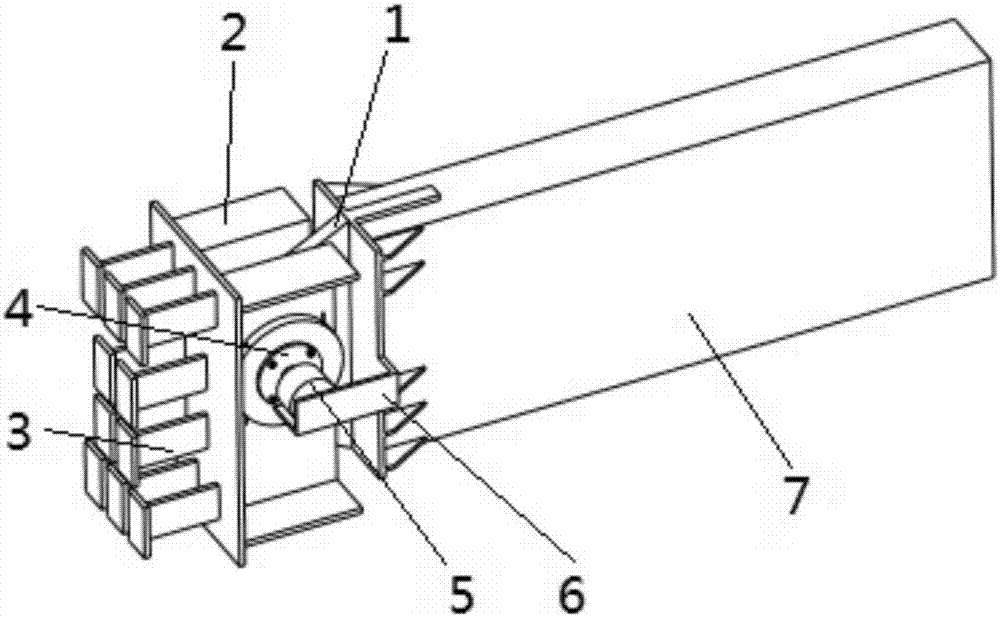

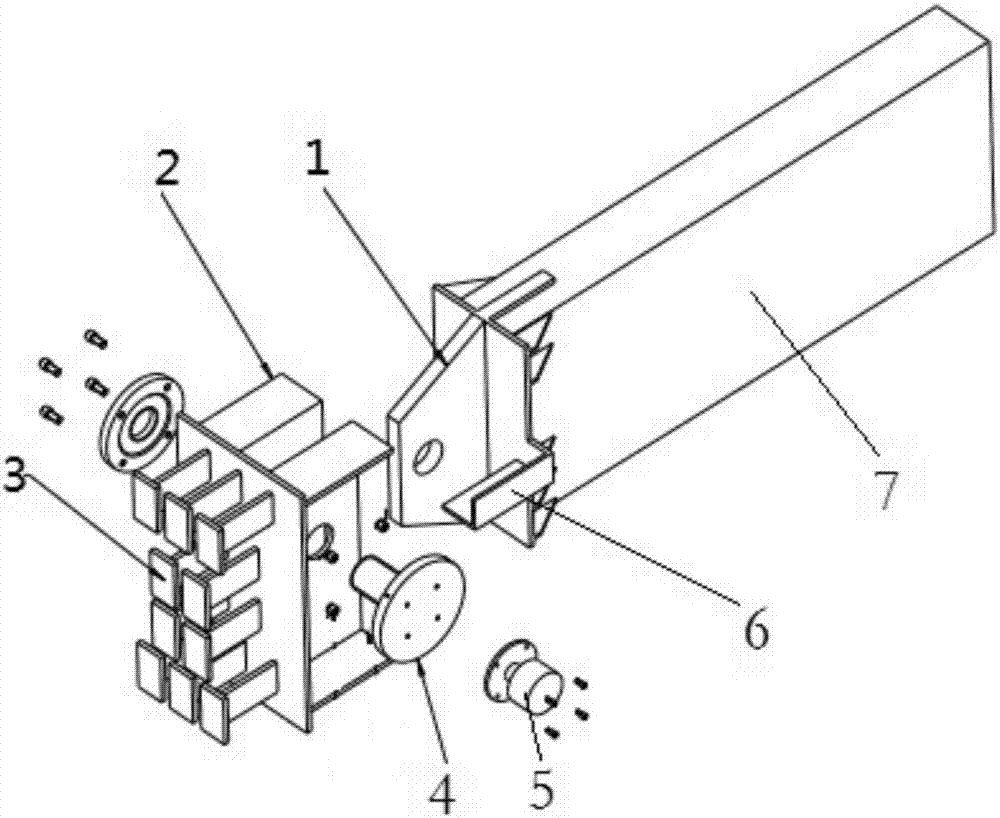

[0031] A method for implementing the connection node between the support frame and the wall of the climbing tower crane, comprising the following steps:

[0032] S1. Weld the second connecting lug plate 2 on the side of the embedded part 3; the two sides of the second connecting lug plate 2 are connected with a constraining plate having a certain angle with the second connecting lug plate 2, and the constraining plate is used to ensure the second connection during welding The lug plate 2 is perpendicular to the embedded part 3, so that the second connecting lug plate 2 can be prevented from being deformed to the outside without a fixing plate during welding.

[0033] S2. Insert the first connecting lug 1 on the side of the main beam 7 of the support frame between the second connecting lugs 2, and insert the pin 4.

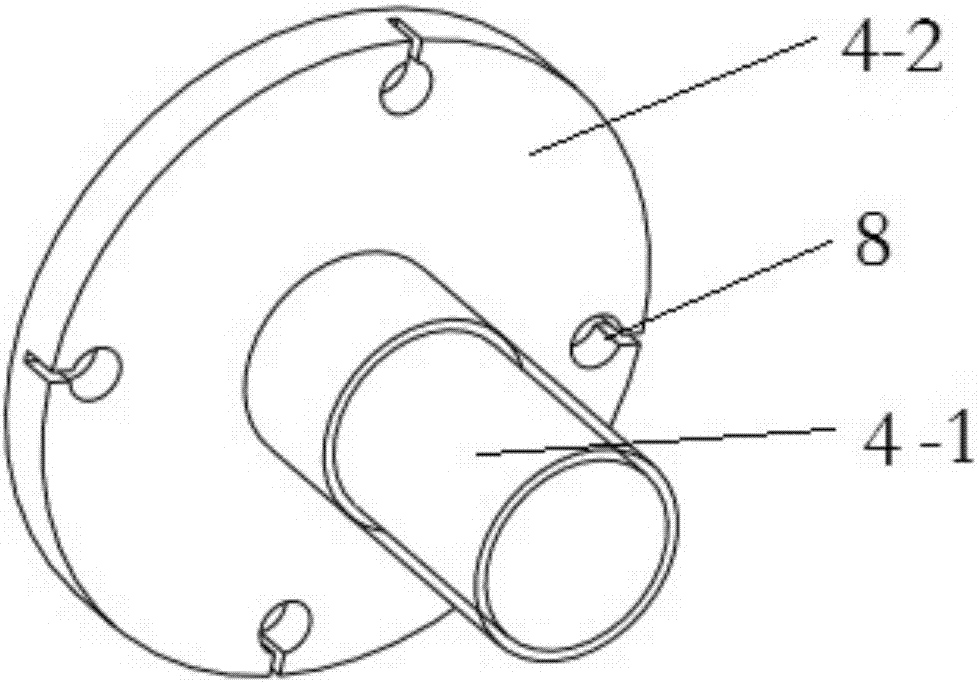

[0034] S3. Put the pre-tightening force applying device 5 on the mounting bracket 6 to apply a pre-tightening force to the pin shaft 4 . A pressure sensor 8 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com