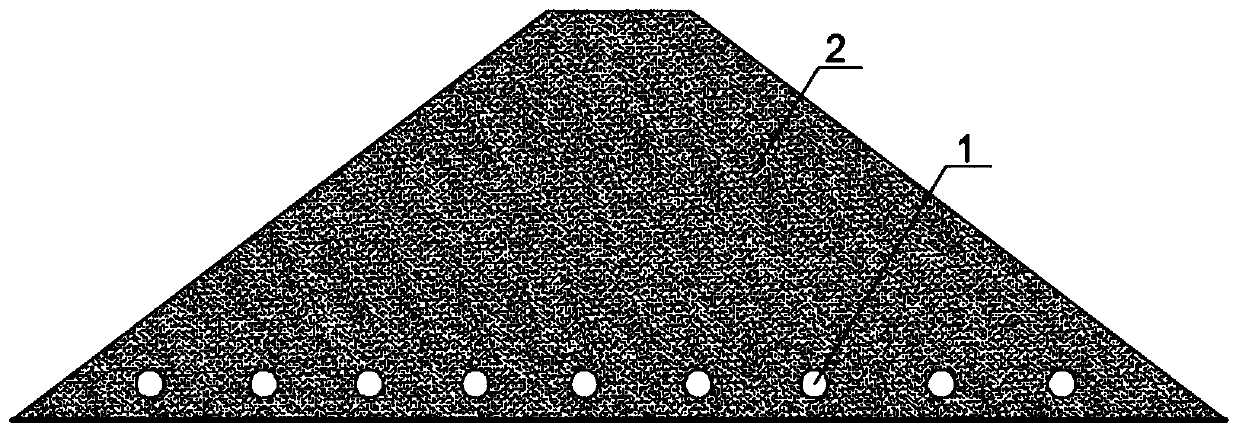

Method for processing fly ash by microorganisms and producing building materials from fly ash

A technology of processing method and production method, applied in the fields of energy and environment, to achieve the effects of high dry density, lower concrete cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

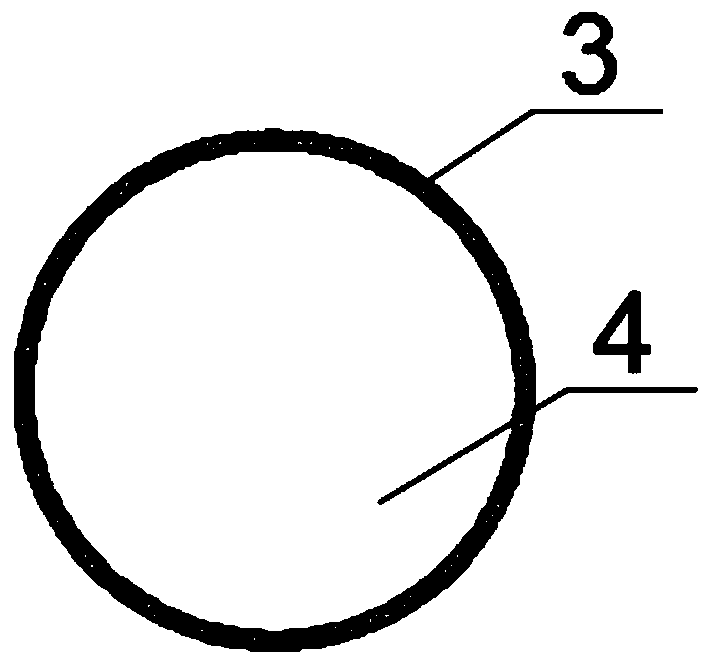

Method used

Image

Examples

Embodiment 1

[0032] Step 1. Preparation of Bacillus pasteurian bacteria liquid:

[0033] Bacterial freeze-dried powder activation: The purchased Bacillus sporosarcina pasteurii (National Culture Collection No. ATCC11859) was vacuum-dried in the state of freeze-dried powder and stored in an ampoule bottle. Prepare liquid medium first, each liter of medium contains 20g of yeast extract, 25mg of manganese sulfate, 5mg of nickel chloride, 15g of ammonium chloride, and adjust the pH to 9-10 with 1mol / L sodium hydroxide. The culture medium and the solid culture slant for inoculation were sterilized by high-temperature steam at 121°C for 20 minutes, and then placed in a sterile operating table to cool down before use. Heat the upper end of the ampoule bottle with an alcohol lamp, drop a few drops of water to break it, take out the inner tube with tweezers, drop 1ml of the above prepared medium to dissolve the dry powder, then pour it into a culture tube containing 6ml of culture medium, and mix w...

Embodiment 2

[0042] This embodiment is an evaluation embodiment of the reinforcement effect of treating fly ash deposits with different concentrations of Bacillus pasteurian bacteria liquid in the treatment method of the above-mentioned embodiment 1.

[0043] Step 1. The lower limit of bacterial concentration

[0044] Cultivate the Pasteurella bacterium liquid by the method in embodiment 1, culture time is less than 40h, or the higher bacterium liquid of concentration is diluted to 10 7After the concentration of cfu / mL is below, process the fly ash accumulation body, the concentration of nutrient solution is 0.5mol / L (the ratio of calcium chloride to urea is 1:1), the efficiency of processing fly ash is low, and the fly ash is difficult to cement into a block .

[0045] Step 2. The upper limit of bacterial concentration

[0046] Centrifuge the bacteria solution normally cultured for 40-60 hours to increase the concentration to 10 9 Above cfu / mL, take samples from different parts of the ...

Embodiment 3

[0050] This example is an example of evaluating the effect of using different concentrations of urea and calcium chloride nutrient solution to treat fly ash deposits in the above treatment method.

[0051] Step 1. Consider microbial treatment of fly ash deposits with different concentrations of nutrient solution

[0052] This example uses about 3×10 8 Cfu / mL concentration of Bacillus Pasteurella bacteria solution to treat fly ash accumulations, the amount of microbial bacteria solution is controlled between 100L and 200L per ton; the concentration and ratio of urea and calcium chloride in the nutrient solution are changed, and nutrition is perfused 8 times solution, the total amount of nutrient solution was 5 times the total amount of bacterial solution added; details are shown in Table 2.

[0053] Table 2

[0054]

[0055]

[0056] Step 2. Detection of reaction efficiency and reinforcement effect

[0057] Collect the effluent of each test, detect the calcium ion conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com