Designing of mix ratio of high-performance recycled concrete

A technology of recycled concrete and mix ratio design, applied in the field of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0041] A high-performance recycled concrete mix design, the method is as follows:

[0042] (1) Determine the preparation strength f′ of recycled concrete cu,0 :

[0043] The formula is as described in (I), f' cu,0 =f' cu,k +tσ (I);

[0044] (2) Determine the compressive strength of cement f ce :

[0045] The formula is as described in (II), f ce = γ c f ce,k (II);

[0046] (3) Regression coefficient of recycled aggregate α′ a ,α′ b value;

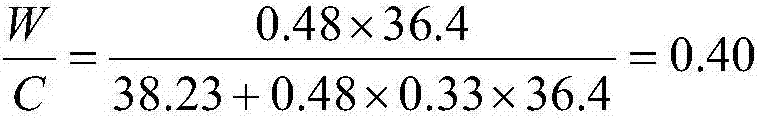

[0047] (4) Determine and calculate the water-cement ratio of recycled concrete

[0048] The formula is as described in (III),

[0049] (5) Calculation of additional water consumption of recycled concrete:

[0050] The formula is as described in (IV), m Δw =2.15%m RCAm Δw =2.15%m RCA (IV);

[0051] (6) Determine the unit water consumption of recycled concrete:

[0052] The formula is as described in (V), m' w0 =165+m Δw (V);

[0053] (7) Determine the amount of recycled concrete cement:

[0054] The formula is ...

Embodiment 8

[0064] Ordinary Concrete Mix Ratio

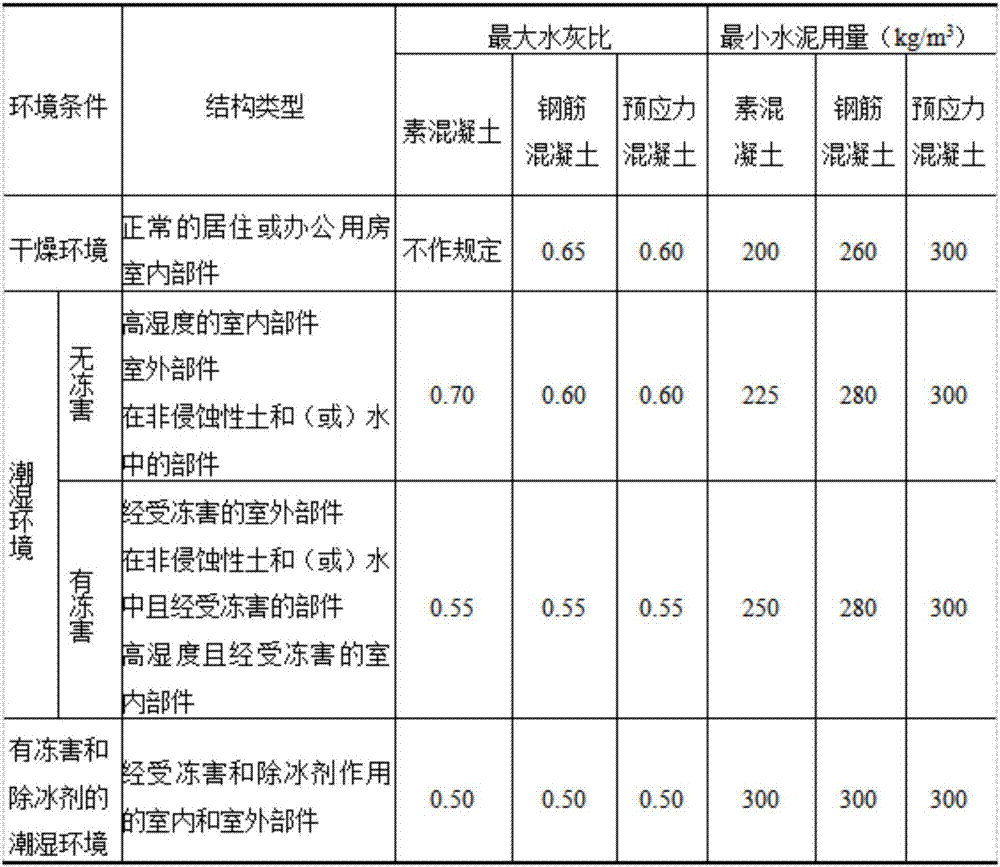

[0065] The basic idea of the mix ratio design of ordinary concrete in my country is: the mix ratio design of concrete depends on the three parameters of water-cement ratio, water consumption and sand rate. According to the preparation strength of concrete and the actual strength of cement, the water-cement ratio is calculated by the Bolomy formula; the water consumption per unit cubic concrete is determined according to the slump and the maximum particle size of coarse aggregate, and then according to the coarse aggregate According to the maximum particle size and water-cement ratio, select the appropriate sand rate, and finally determine the amount of sand and gravel according to the volume method or mass method, and complete the mix ratio of concrete after trial mixing and adjustment. The following takes the preparation of ordinary concrete with a strength grade of C30 as an example to design the mix ratio of ordinary concrete.

[0066...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com