Shield tail sealing grease for high water pressure resistant shield and preparation method thereof

A technology of shield tail sealing and sealing grease, which is applied in the petroleum industry, lubricating compositions, etc., can solve problems such as poor balance, affecting normal construction, and potential safety hazards, and achieves the effect of low price and good pumpability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The embodiment of the present invention also provides a preparation method of shield tail sealing grease for high water pressure resistant shield tunneling. It is used for the above-mentioned sealing grease, and each component is obtained according to the above-mentioned sealing grease formula, including the following steps:

[0023] Dissolve polyisobutylene in base oil 150N, heat up to 50-100°C, stir for 20-40 minutes to obtain a mixed solution; inject the mixed solution into a kneader, set the temperature of the kneader to 50-100°C, then add lignocellulose, Mineral fiber, after stirring for 10 minutes, continue to add organic bentonite, calcium carbonate, talcum powder and barium sulfate; after stirring for 10 minutes, add lithium-based grease, and stir for 30-60 minutes, and filter through a filter with a pore size of 10-15mm to obtain High water pressure resistant shield tail seal grease.

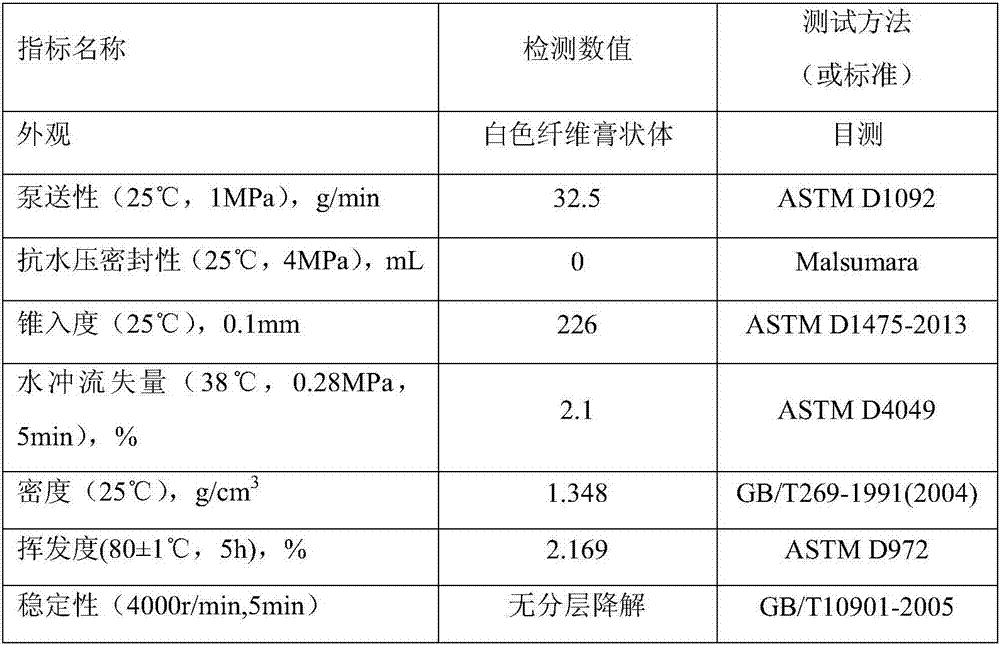

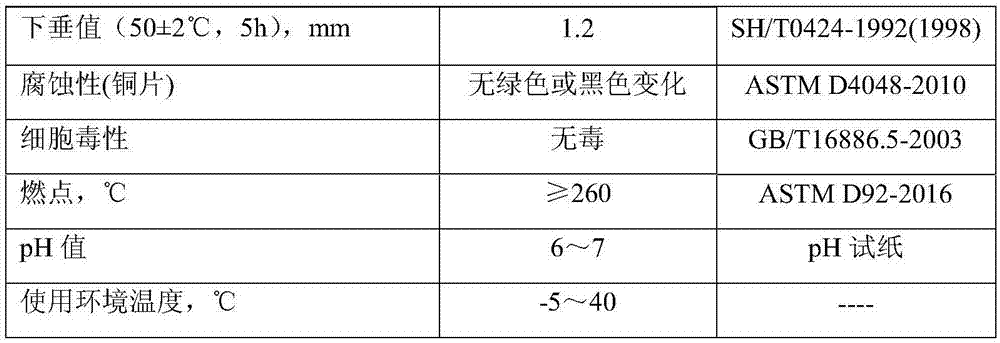

Embodiment 1

[0026] In the present embodiment, the high water pressure resistant shield is used for the shield tail sealing grease, and its formula components are: 14% of base oil 150N, 21% of polyisobutylene (PB1300, PB2400), 17% of lithium base grease, and 6% of organic bentonite , lignocellulose 5%, mineral fiber (sepiolite) 3%, calcium carbonate (heavy) 24%, barium sulfate 5% and talc 5%.

[0027] The preparation process of the shield tail seal grease for high water pressure shield tunneling is as follows: First, dissolve polyisobutylene (PB1300 and PB2400) in base oil 150N, heat up to 50-100°C, and stir for 20-40min; inject the mixed solution into the kneader , set the temperature of the kneader to 50-100°C, then add lignocellulose, mineral fiber (asbestos, sepiolite); after stirring for 10 minutes, continue to add organic bentonite, calcium carbonate (heavy), talcum powder and barium sulfate; stir After 10 minutes, add lithium-based grease, stir for 30-60 minutes, and filter through ...

Embodiment 2

[0033] In the present embodiment, the shield tail sealing grease for high water pressure resistant shield, its formula components and weight percentages are: base oil 150N 12%, polyisobutylene (PB1300, PB2400) 23%, lithium base grease 17%, organic bentonite 4%, lignocellulose 4%, mineral fiber (sepiolite) 4%, the balance is calcium carbonate (heavy) 26%, barium sulfate 8% and talcum powder 2%.

[0034] The preparation method of the shield tail sealing grease for high water pressure resistant shield tunneling is the same as that in Example 1, and will not be described again.

[0035]The test of the shield tail sealing grease sample prepared in this embodiment for high water pressure resistant shield tunneling can withstand a water pressure of 6 MPa at 25°C in the laboratory. The physical and chemical indicators of the shield tail sealing grease for high water pressure resistant shield tunneling are the same as those in the first embodiment.

[0036] Compared with the shield ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com