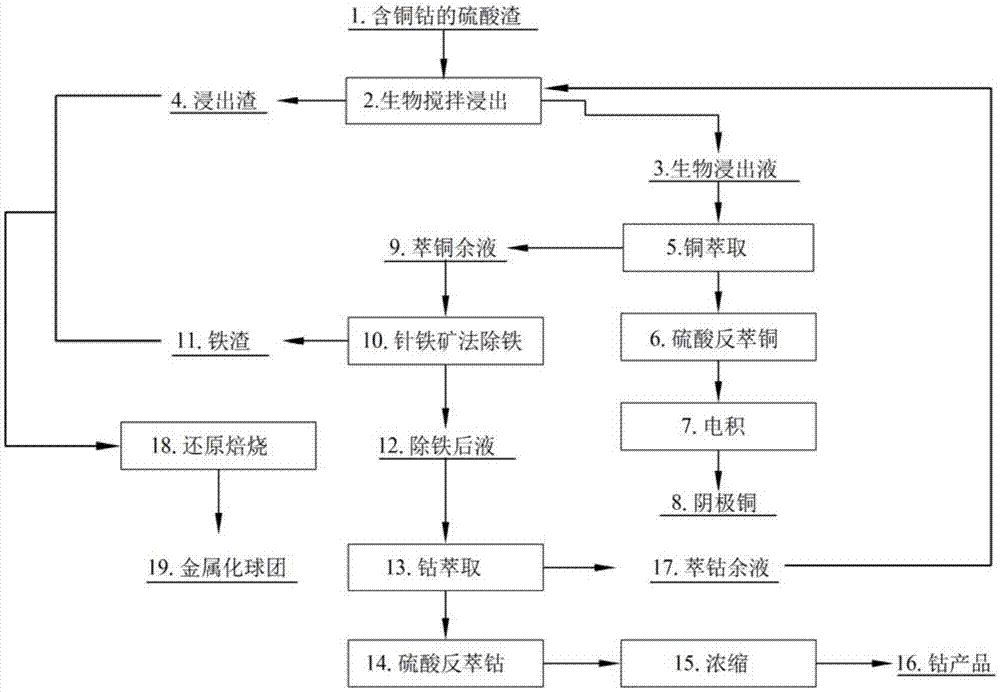

Process for comprehensive recovery of copper-cobalt-containing sulfuric acid slag

A sulfuric acid slag, copper-cobalt technology, applied in the direction of photographic process, photographic auxiliary process, process efficiency improvement, etc., can solve the problems of affecting quality, waste, high sulfur content of metallized pellets, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The invention is applied to the sulfuric acid slag produced by the acid production of a certain pyrite concentrate in the Congo. The grade of copper in the sulfuric acid slag is 0.5%, the grade of cobalt is 0.06%, and the grade of iron is 68.54%.

[0021] (1) Bioleaching

[0022] The sulfuric acid slag was subjected to bioleaching, the pH value was maintained at 2.0, the pulp concentration was 25%, and Sulfobacillus thermosulfiooxidans 6Y-1 was inoculated for leaching. The reaction period was 3 hours, and the temperature was 65°C. Continuous leaching was adopted. The leaching rates of copper and cobalt both reached 85%.

[0023] (2) Recovery of copper in leaching solution

[0024] The concentration of copper in the leaching solution reaches above 0.5g / L, and M5640 is used for extraction, the extraction ratio (v / v) A:O=4:1, three-stage countercurrent extraction, sulfuric acid (180g / L) back extraction ratio (v / v) O:A=2:1, after two-stage stripping, enter electrowinnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com