Spiral shaft type separating machine for filament and staple fibers

A technology of fiber separator and screw shaft, which is applied in fiber separation, fiber treatment, textiles and papermaking, etc. It can solve the problems of poor dust removal effect, achieve the effect of enlarged space, long spindle and high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with accompanying drawing and embodiment, and wherein accompanying drawing constitutes a part of this application, but those skilled in the art should know that the following embodiment is not the only limitation that the technical scheme of the present invention is done, Any equivalent transformation or modification made under the spirit of the scheme shall be deemed to belong to the protection scope of the present invention.

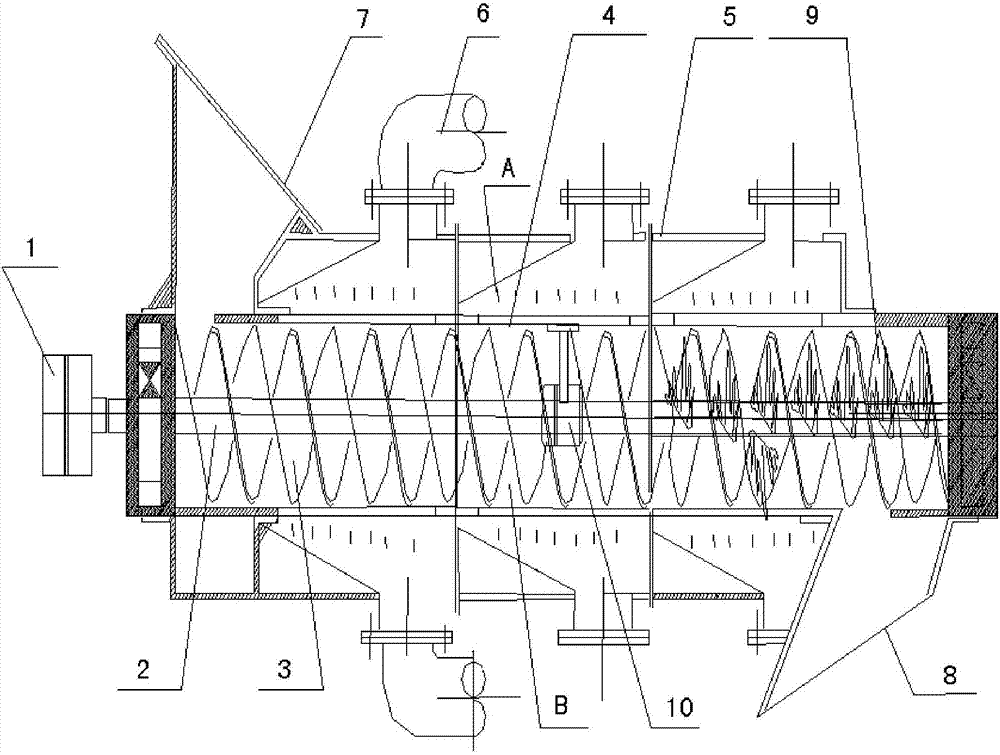

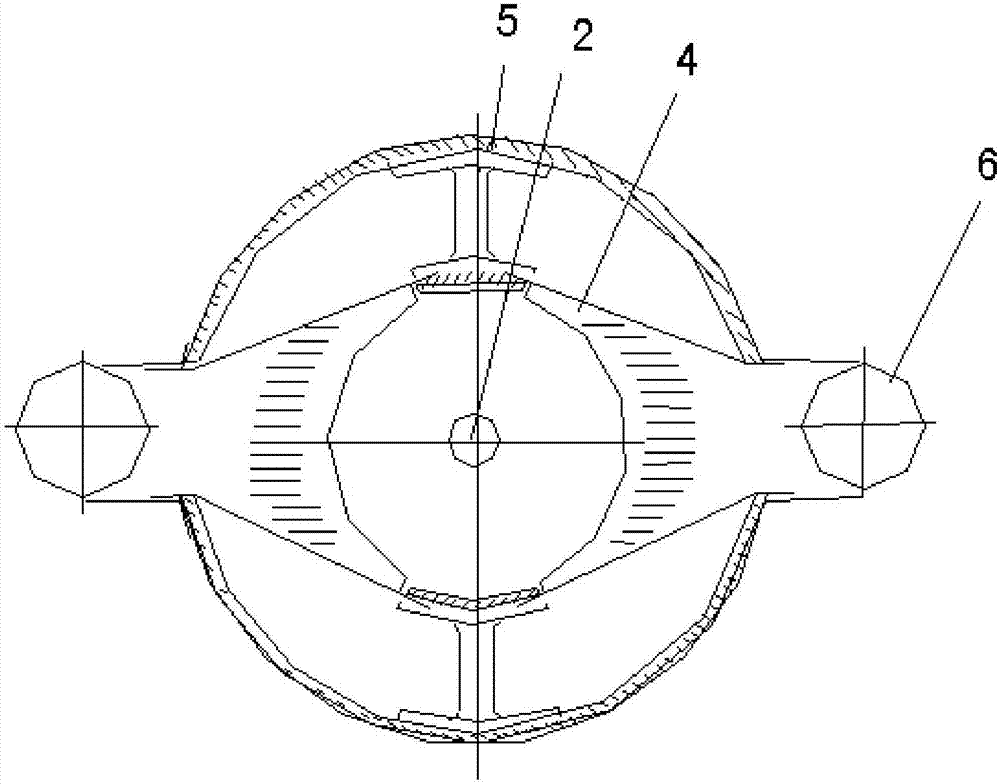

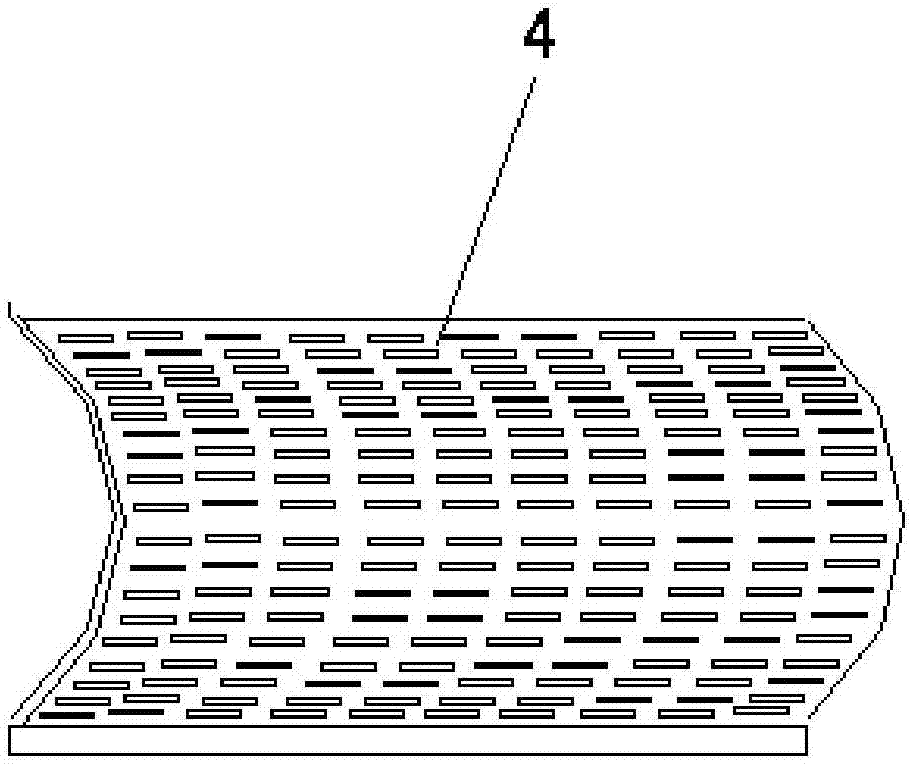

[0027] Such as figure 1 , figure 2 As shown, the machine consists of motor 1, main shaft 2, screw blade 3, screen cylinder 4, host casing 5, negative pressure tube 6, feed hopper 7, discharge hopper 8 and other main components. The main body of the device is constructed of metal.

[0028] The motor 1 is connected to the main shaft 2 through a coupling, the main shaft 2 is supported by the frame and placed in the screen cylinder 4, and the helical blade 3 is installed on the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com