A pilot test method for producing high-purity mung bean protein powder

A protein powder, mung bean technology, applied in the protein composition of vegetable seeds, protein food ingredients, food science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

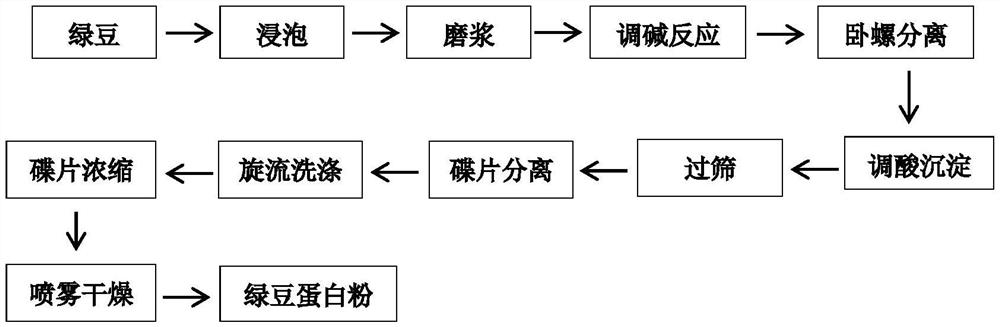

Method used

Image

Examples

Embodiment 1

[0030] (1) Take 100Kg mung beans (protein content 22%) from a certain place of origin, rinse the mung beans once with water according to the weight ratio of mung beans and water of 1:5, drain the washing water, and then soak the mung beans with the same weight of water for 2 hours;

[0031] (2) The mixed liquid of mung bean and water obtained in step (1) enters a pulverizer for coarse crushing. The coarse pulverizer has a built-in screen of 40 mesh. During the pulverization process, continue to add clear water to mix the mung bean milk to prevent the temperature from rising. The mung bean milk is transported to the colloid mill through the pipeline for fine crushing, and the crushed mung bean milk is passed through a 100-mesh vibrating sieve to remove the sieved matter;

[0032] (3) adjusting the pH value of the mung bean milk obtained in step (2) to 8.5 using an aqueous sodium hydroxide solution with a concentration of 10% by weight, and insulated for 30 minutes;

[0033] (4)...

Embodiment 2

[0039] (1) Take 100Kg of mung beans (protein content 22%) from a certain place of origin, rinse the mung beans once with water according to the weight ratio of mung beans and water of 1:4, drain the washing water, and then soak the mung beans with the same weight of water for 3 hours;

[0040] (2) The mixed liquid of mung bean and water obtained in step (1) enters a pulverizer for coarse crushing. The coarse pulverizer has a built-in screen of 40 mesh. During the pulverization process, continue to add clear water to mix the mung bean milk to prevent the temperature from rising. The mung bean milk is transported to the colloid mill through the pipeline for fine crushing, and the crushed mung bean milk is passed through a 100-mesh vibrating sieve to remove the sieved matter;

[0041](3) Adjust the pH value of the mung bean milk obtained in step (2) to 8.0 using an aqueous sodium hydroxide solution with a concentration of 10% by weight, and insulate and react for 30 minutes;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com