A method and structure for channel anti-seepage and anti-frost heave

An anti-frost and channel technology, applied in artificial waterways, buildings, water conservancy projects, etc., can solve the problems of anti-frost structure damage, poor anti-frost effect, concrete frost-heave damage, etc., and achieve strong anti-ice push ability and anti-frost effect. Good, improve the effect of stress conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below through specific examples.

[0032] A method for anti-seepage and anti-frost heave of canals, the method steps are as follows:

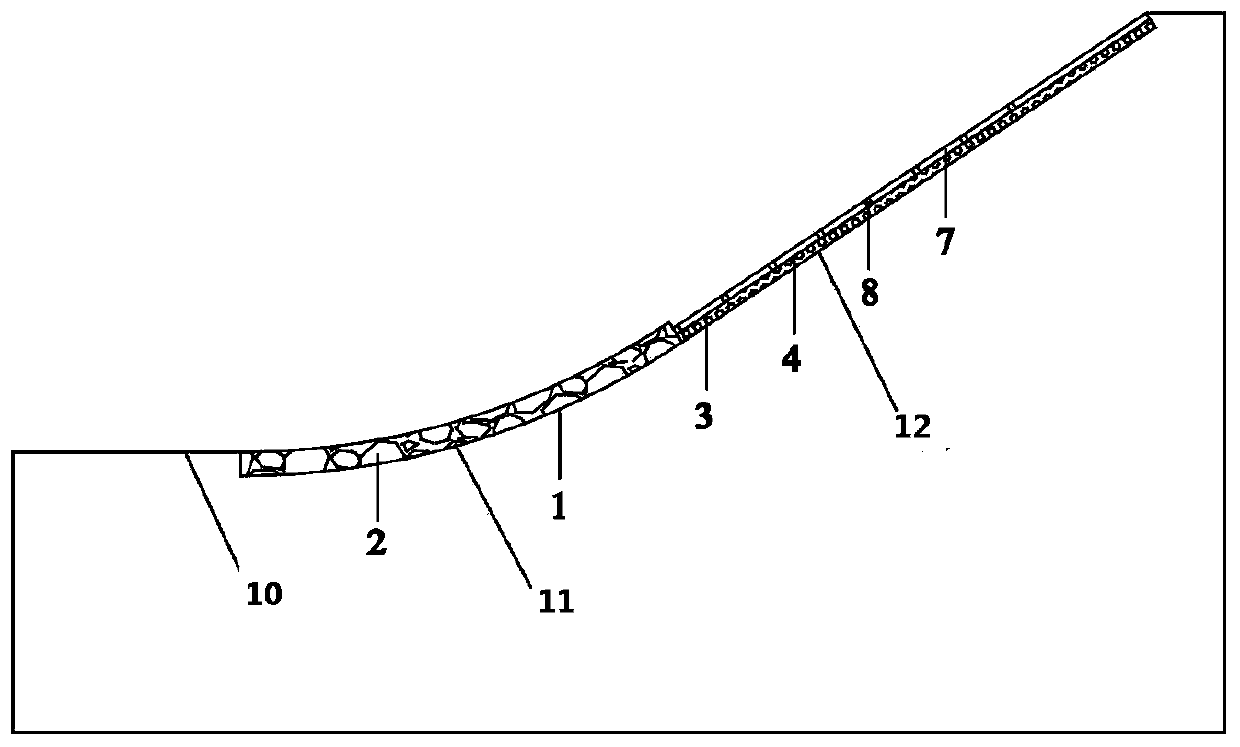

[0033] 1) Roll one side of the canal and then level it so that the leveled canal side is on a horizontal plane, the bottom of the canal is an arc-shaped section with an arc length of 1.97m, and the inclination angle of the canal is 40°, along the canal slope from the bottom of the canal to the top of the canal Lay geotextile 1, geotextile 1 is 500g / m 2 , Concrete 2 is poured along the channel connecting section 11 on the outside of geotextile 1. Concrete 2 is C20 concrete with a thickness of 200mm. The arc-shaped slope foot of the concrete solves the problem that the slope foot of the rectangular channel is easy to be damaged by frost heave, and has good mechanical properties. Can well adapt to frost heave deformation;

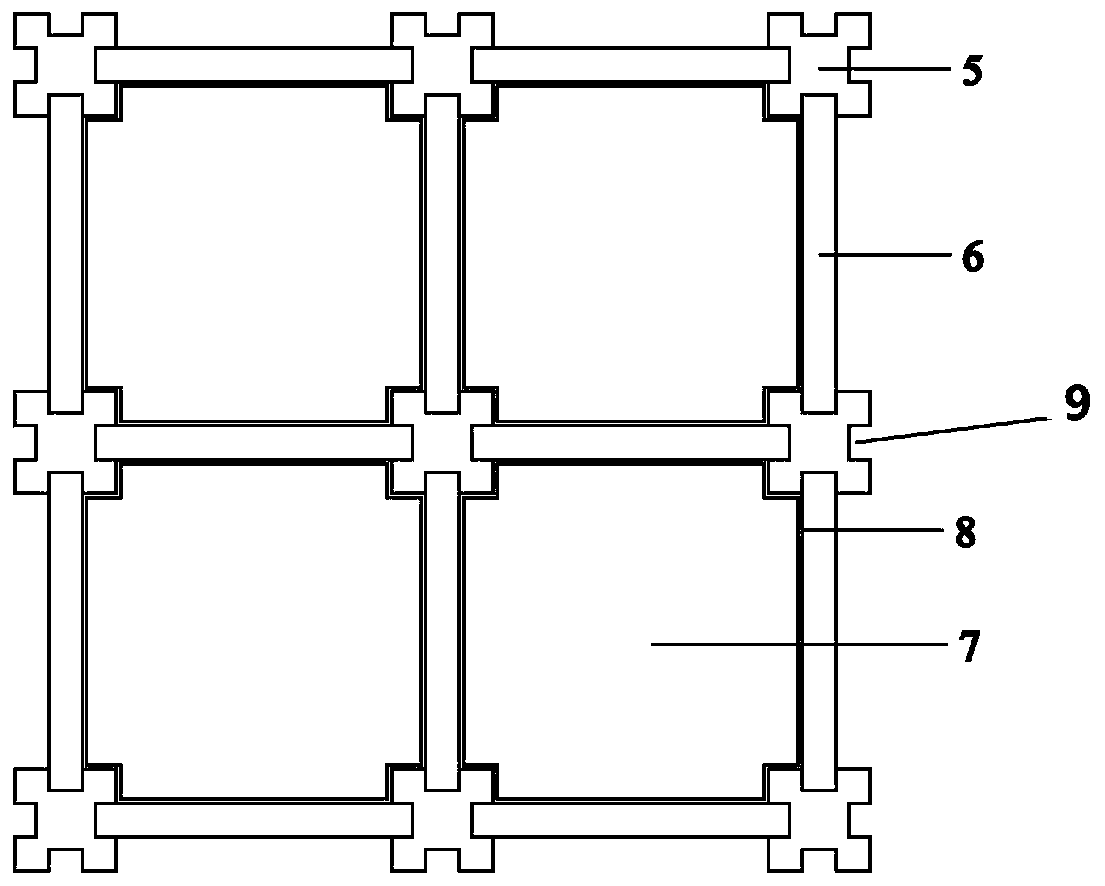

[0034] 2) The edges of both ends of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com