Deep-sea cobalt crust cutting device based on high-pressure water jet flow

A technology of high-pressure water jet and cutting device, which is applied in mineral mining, earth square drilling, special mining, etc. It can solve the problems of fast wear of the reamer head, severe mechanical vibration, and high ore dilution rate, so as to ensure cutting accuracy and prevent Diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

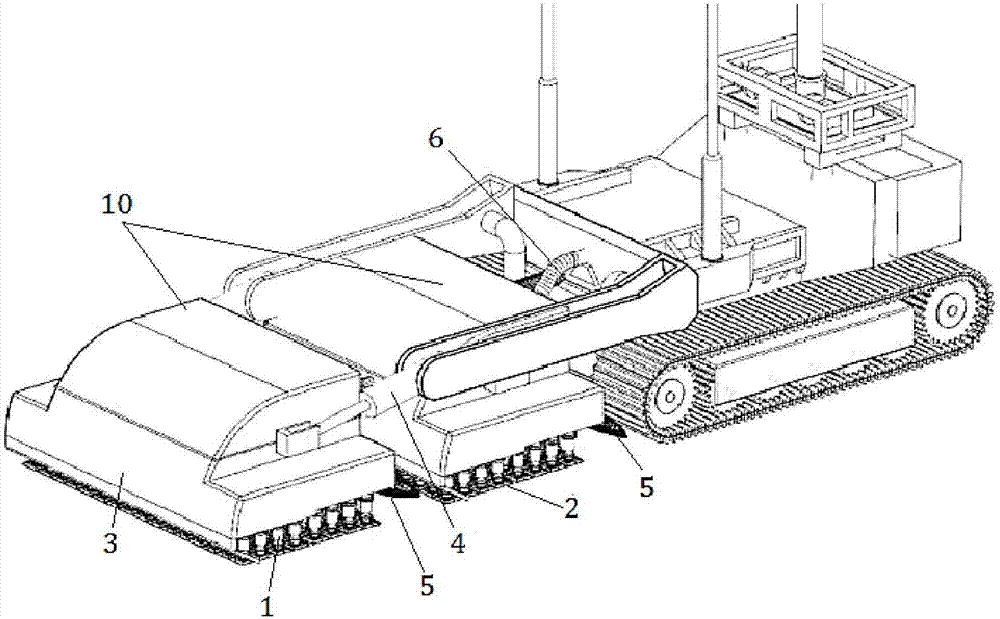

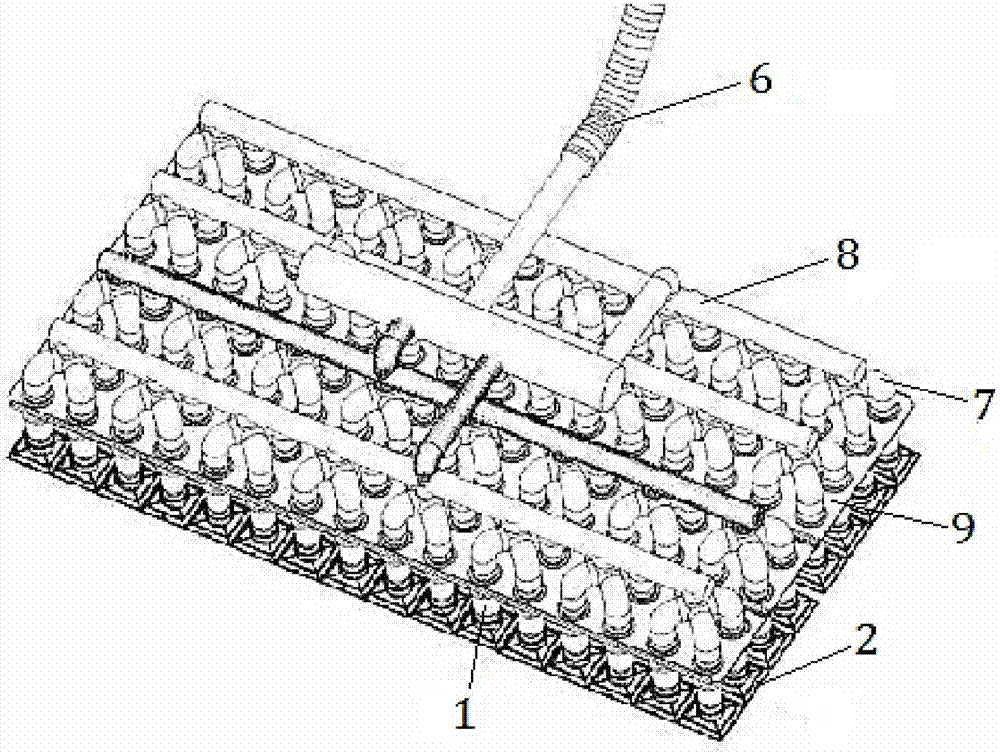

[0030] Such as figure 2 and Figure 4 As shown, this embodiment includes: a high-pressure water delivery system, a high-pressure water jet nozzle unit and a nozzle bracket 2, wherein: the high-pressure water delivery system is connected to the high-pressure water jet nozzle unit, and the top of each nozzle 1 in the high-pressure water jet nozzle unit is arranged on On the support frame 9, the bottom of each nozzle 1 is spherical and connected to the nozzle bracket 2 through a spherical hinge structure;

[0031] The high-pressure water delivery system includes a connected high-pressure water main pipeline 6 and a high-pressure water pipeline 8, wherein: the high-pressure water pipeline 8 is arranged in one-to-one correspondence with each group of nozzles 1 and is connected by a telescopic tube 7;

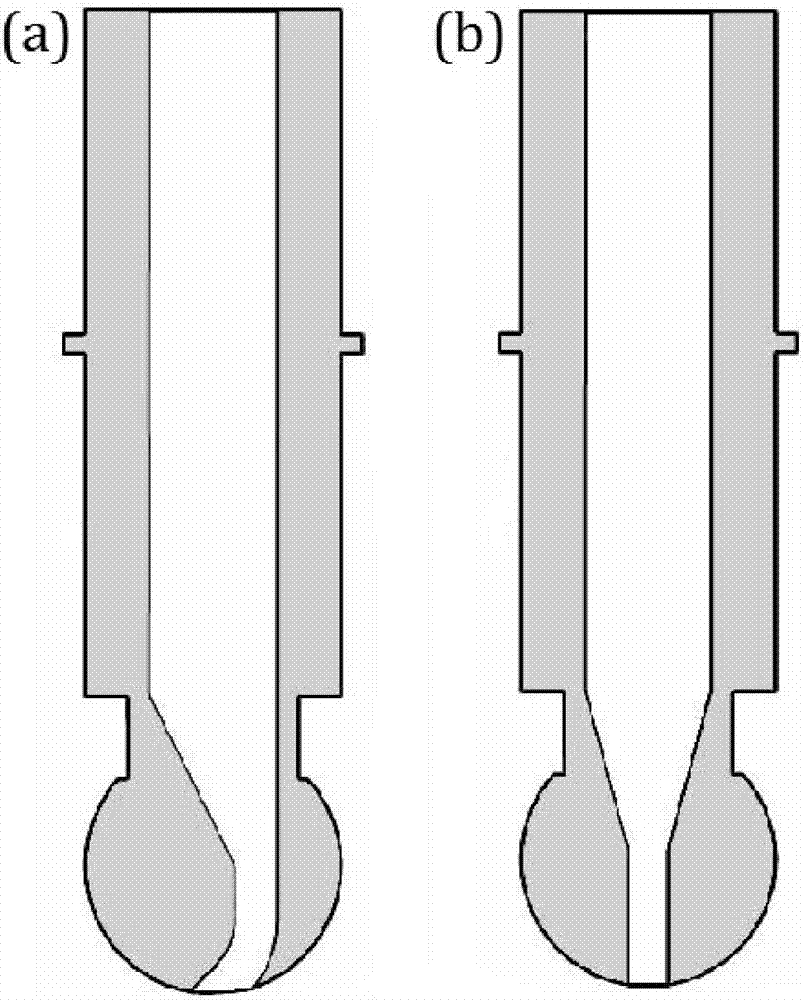

[0032] Such as Figure 5 As shown, the nozzle bracket 2 is a hollow frame structure, a spherical shell is fixed inside the frame, and an injection port is opened on the spherical ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap