All-season refrigerant rapid filling and recovery system for compressor test system

A testing system and recovery system technology, applied in refrigerators, refrigerants, refrigeration components, etc., can solve problems such as strong dependence, affecting the performance test progress of refrigeration compressors, and the inability of recovery devices to open the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

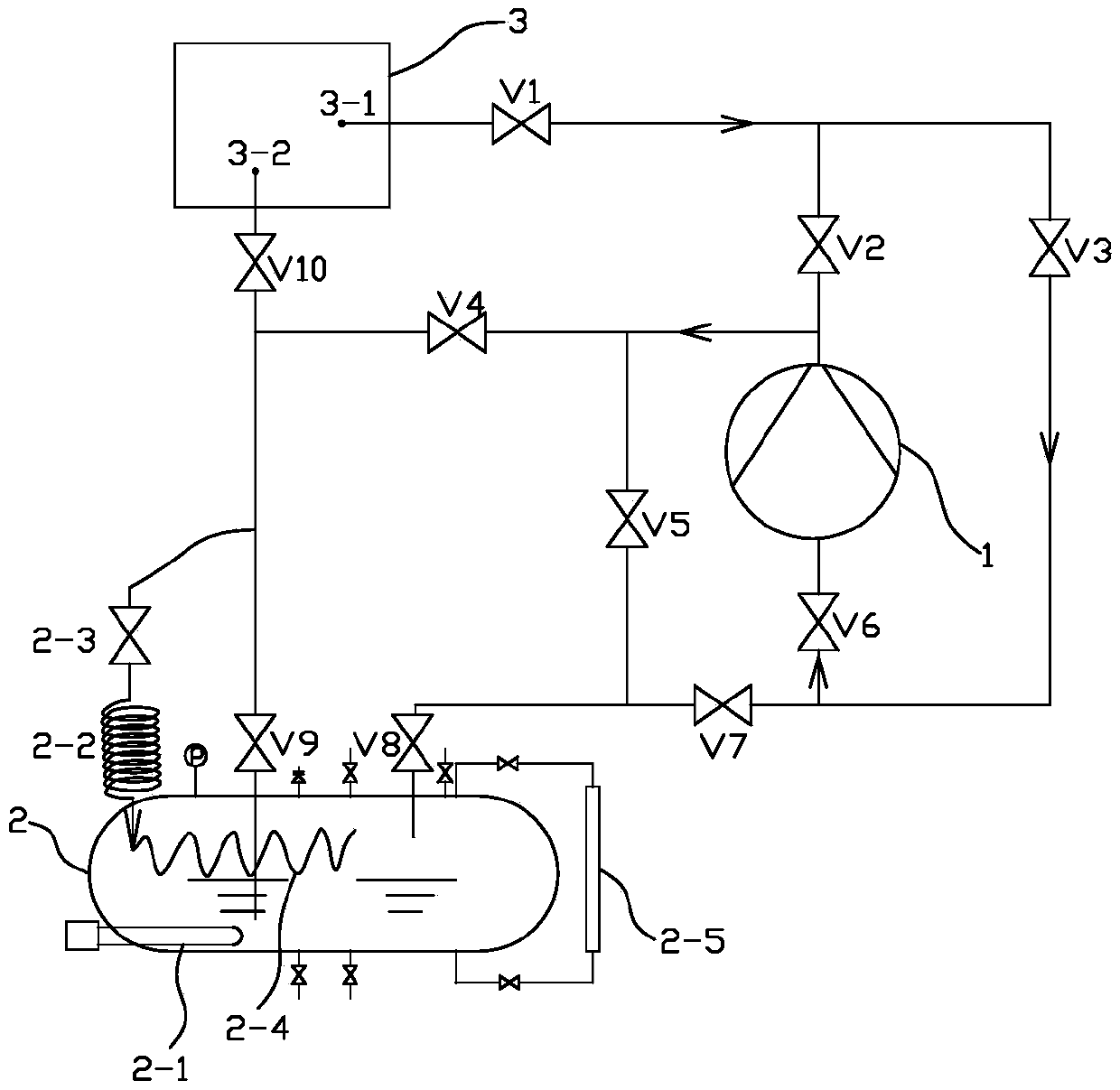

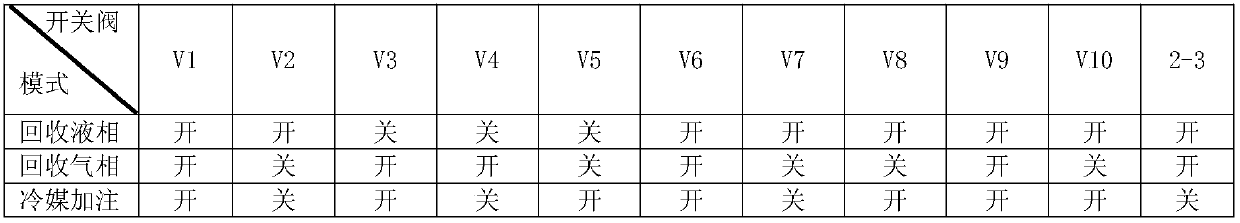

[0025] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

[0026] The present invention includes a compression condensing unit 1 and a refrigerant storage tank 2;

[0027] When the refrigerant is filled: the inlet of the compression condensing unit 1 is connected to the gas-phase refrigerant interface 3-1 provided on the compressor test system 3, and the outlet of the compression condensing unit 1 is connected to the refrigerant storage tank 2. The refrigerant storage tank 2 communicates with the liquid-phase refrigerant interface 3-2 on the compressor test system 3; the refrigerant storage tank 2 is provided with a heating device 2-1 for heating and vaporizing the liquid-phase refrigerant; The device 2-1 includes an electric heating tube arranged in the refrigerant storage tank 2;

[0028] When the refrigerant is recovered: the inlet of the compression condensing unit 1 is connected to the refrigerant storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com