Method for detecting sedimentation degree of barium sulfate

A technology of barium sulfate and scale, applied in the direction of volume measuring instrument/method, measuring device, measuring capacity, etc., can solve the problems that the detection of sedimentation does not have specific detection, does not involve the production of lead paste, etc., and achieves simple test and detection steps, easy to test The detection result is easy to measure and the test detection accuracy is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

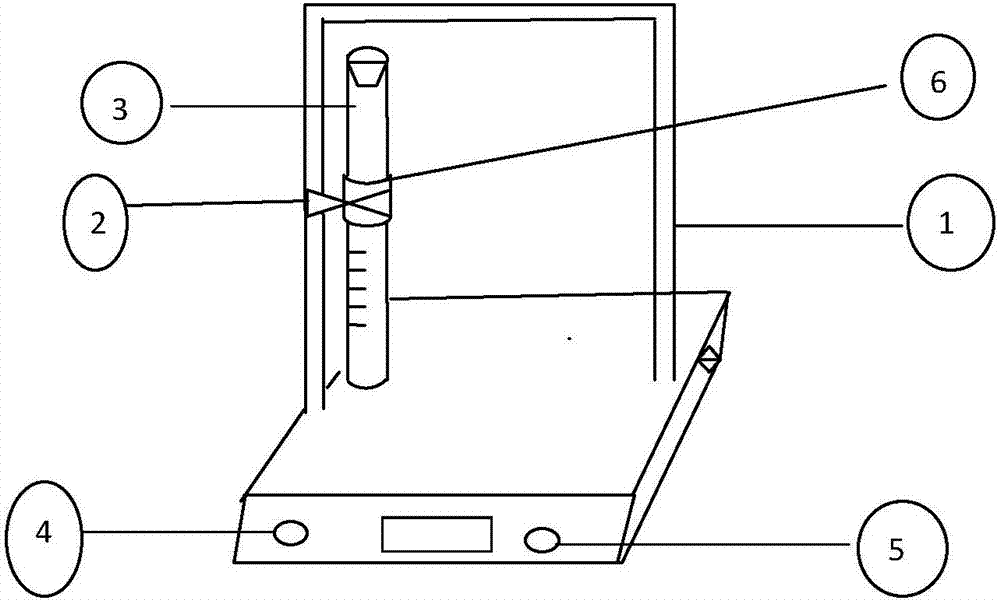

[0023] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0024] Such as figure 1 Shown, the present invention comprises motor frame 1, motor 2, scale colorimetric tube 3 with stopper, motor switch 4, timer, scale colorimetric tube fixture 6; Timer and timer switch 5 link to each other, motor 2 and motor frame 1 is connected, the scaled colorimetric tube 3 is clamped in the scaled colorimetric tube fixture 6, and the scaled colorimetric tube fixture 6 is connected with the motor 2; when the motor switch 4 is turned on, the motor 2 can rotate clockwise or counterclockwise;

[0025] The sedimentation degree of barium sulfate is detected according to the following steps:

[0026] (1) First weigh a certain amount of barium sulfate sample and put it into the graduated colorimetric tube 3 with the stopper removed;

[0027] (2) Add an appropriate amount of water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com