Machine tool main shaft pull broach mechanism reliability testing device

A technology of machine tool spindle and test device, which is applied in the testing of machine/structural components, measuring device, testing of mechanical components, etc., can solve the problems that the performance of the broaching mechanism cannot be fully reflected, and the reliability test of the spindle broaching mechanism cannot be completed. Achieve the effect of eliminating invalid loading force, high reliability, and simple test device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

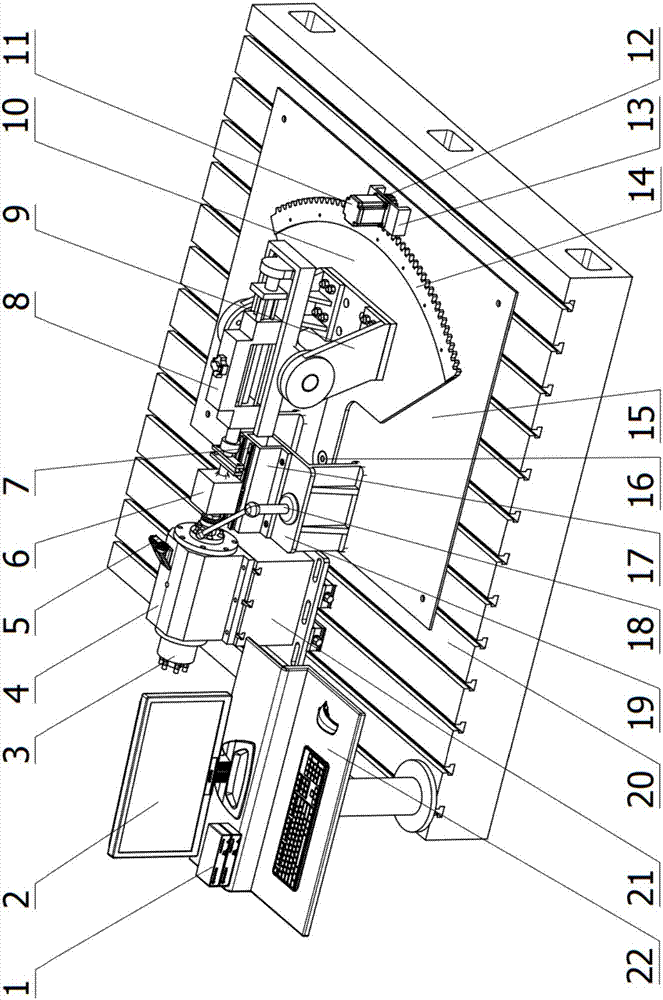

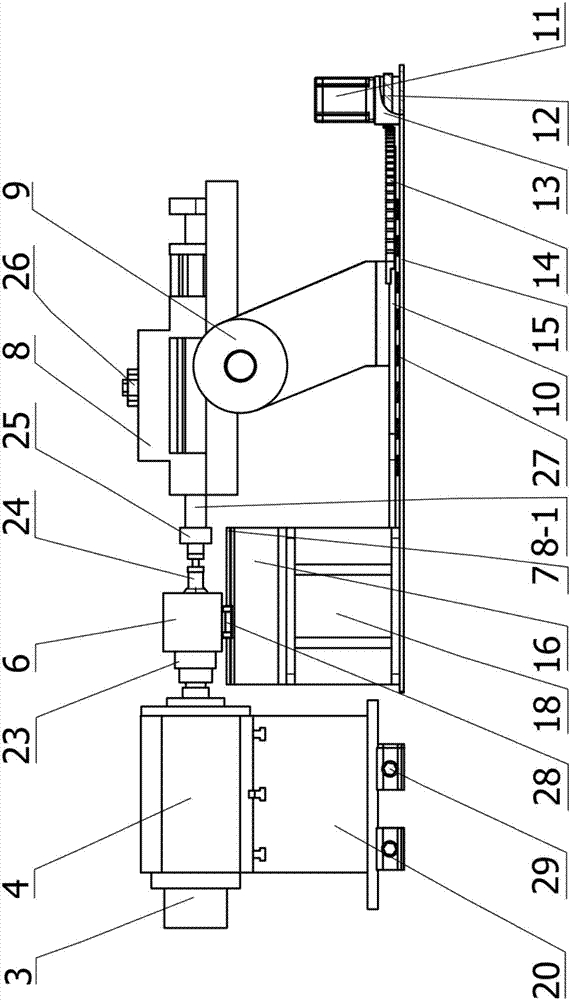

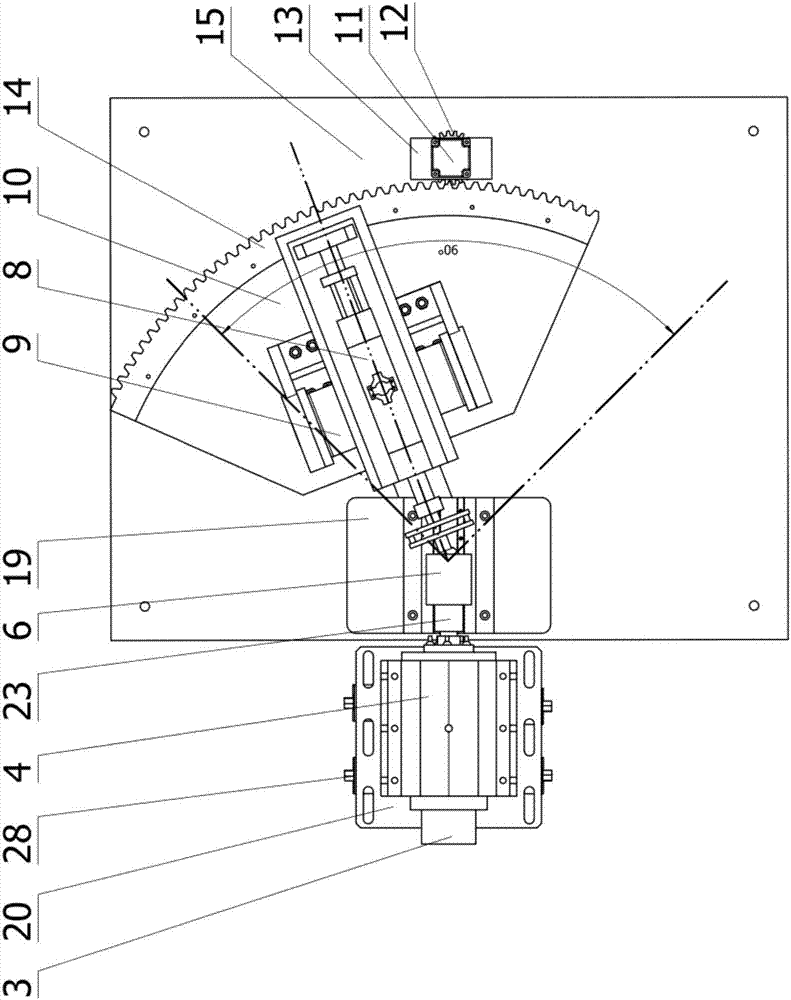

[0051] The present invention is described in detail below in conjunction with accompanying drawing:

[0052] A reliability test device for a main shaft broaching mechanism according to the present invention is composed of four major parts: a main shaft installation module, a simulated tool handle module, a loading module and an auxiliary module. Its function and composition are described as follows:

[0053] The spindle installation module realizes the installation function of the tested spindle. The module includes a main shaft 3, a main shaft pulling claw 3-1, a main shaft holding clamp 4, a main shaft supporting table 21 and a screw trimmer 29;

[0054] The loading module realizes simulating the action of the tool changing manipulator, provides power for changing the tool handle and provides dynamic cutting force that changes in size and direction. This module includes an electro-hydraulic servo loading mechanism 8, a loading rod 8-1, a loading mechanism base 9, a loading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com