Rock brittleness index evaluation method based on full stress-strain curve

A technology of strain curve and rock brittleness, applied in the field of rock mechanics, can solve problems such as only applicable, cumbersome methods, errors, etc., to achieve the effect of strong pertinence, simple operation, and improved rationality and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

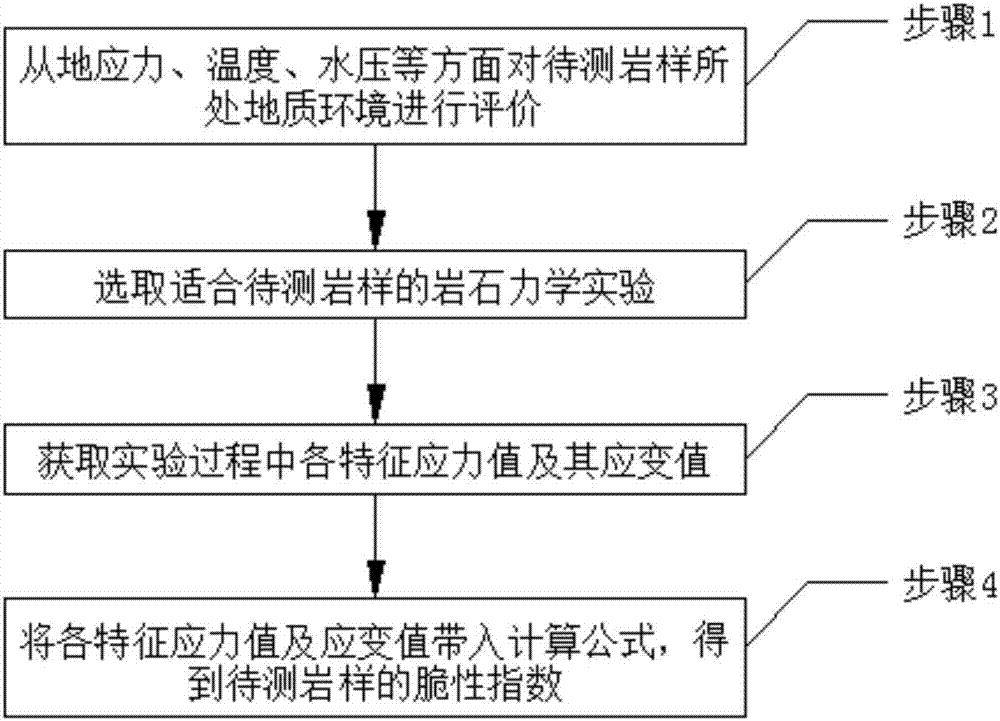

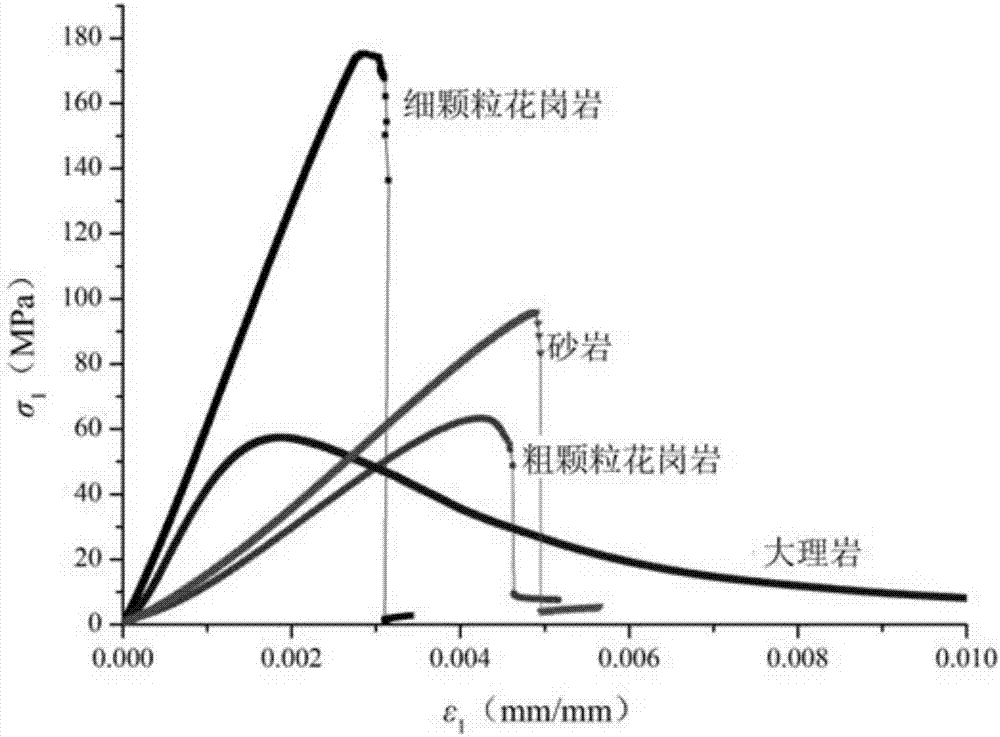

[0025] Evaluate the brittleness index of marble, sandstone, coarse-grained granite, and fine-grained granite exposed on the surface, such as figure 1 As shown, the method for calculating the brittleness index provided by the embodiments of the present invention includes the following steps:

[0026] Evaluate the geological environment of the four rocks: the surface is exposed, the stress is small, and there is no influence of temperature, water pressure, etc.;

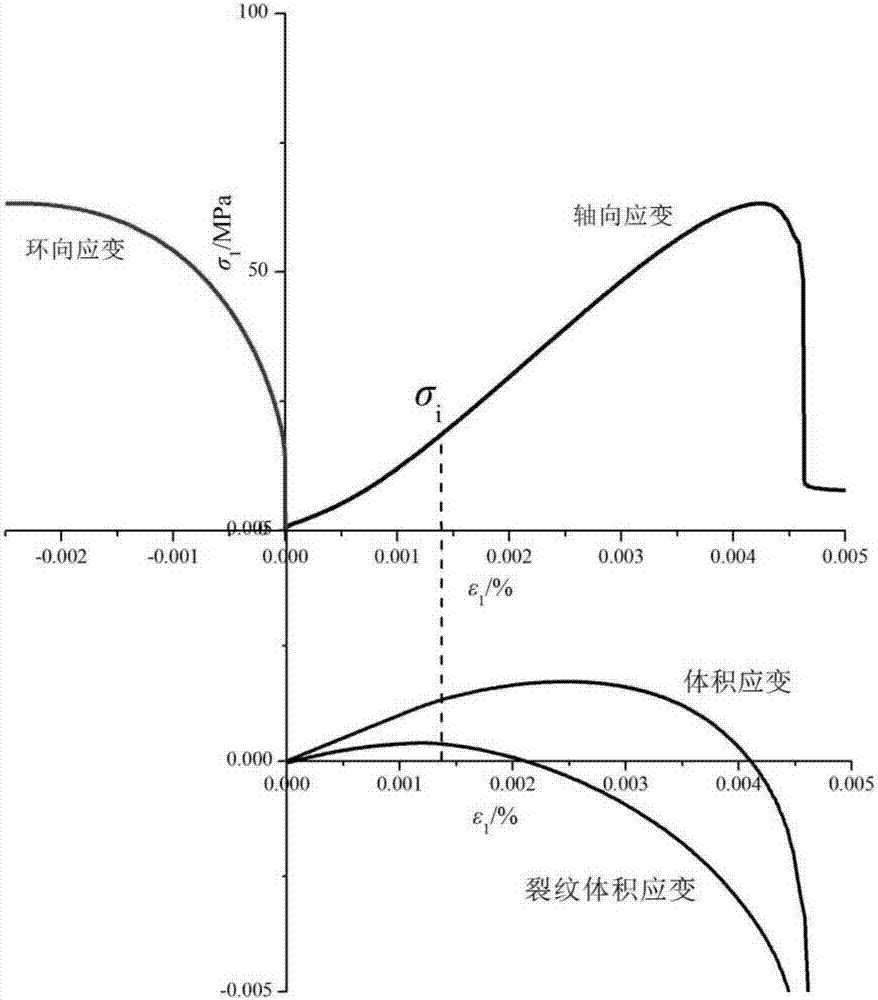

[0027] Due to the simple geological environment of the rock sample, the uniaxial compression experiment was selected. The experimental loading system adopts three-stage control. At the beginning of the experiment, the axial displacement control is adopted. When the axial pressure reaches 70% of the peak strength, it is switched to the circumferential displacement. Control, the circumferential displacement rate increases step by step, the initial setting value is 0.0025mm / s, when the curve reaches the peak value and beg...

Embodiment 2

[0036] Evaluate the brittleness index of marble at 20°C, 40°C, 60°C, and 90°C, such as figure 1 As shown, the method for calculating the brittleness index provided by the embodiments of the present invention includes the following steps:

[0037] Evaluate the geological environment of rocks at four temperatures: rocks with high geothermal temperature are generally buried deep underground, with large in-situ stress and no influence of water pressure;

[0038] The triaxial compression test is selected, and the confining pressure is 20MPa due to the large ground stress;

[0039] The characteristic stress values obtained during the experiment and their corresponding strains are shown in Table 2. The characteristic stress values include crack initiation stress, peak stress, and residual stress;

[0040] Concrete characteristic stress value and strain value thereof of table 2 embodiment two

[0041]

[0042] The calculation method of brittleness index with consideration of ...

Embodiment 3

[0046] Evaluate the brittleness index of marble under water pressure of 0MPa, 4MPa, 8MPa and 12MPa, such as figure 1 As shown, the method for calculating the brittleness index provided by the embodiments of the present invention includes the following steps:

[0047]Evaluate the geological environment of rocks under four kinds of water pressure: rocks with high water pressure are generally buried deep underground, with abundant groundwater, large in-situ stress, and no temperature influence;

[0048] The triaxial compression test is selected, and the confining pressure is 20MPa due to the large ground stress;

[0049] The characteristic stress values obtained during the experiment and their corresponding strains are shown in Table 3. The characteristic stress values include crack initiation stress, peak stress, and residual stress;

[0050] Concrete characteristic stress value and strain value thereof of table 3 embodiment three

[0051]

[0052] Bring into the calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com