Pennisetum sinese planting machine

A planting machine and giant fungus grass technology, which is applied in planting methods, transplanting machinery, applications, etc., can solve the problems of low investment in research and development, low production efficiency, large width and volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

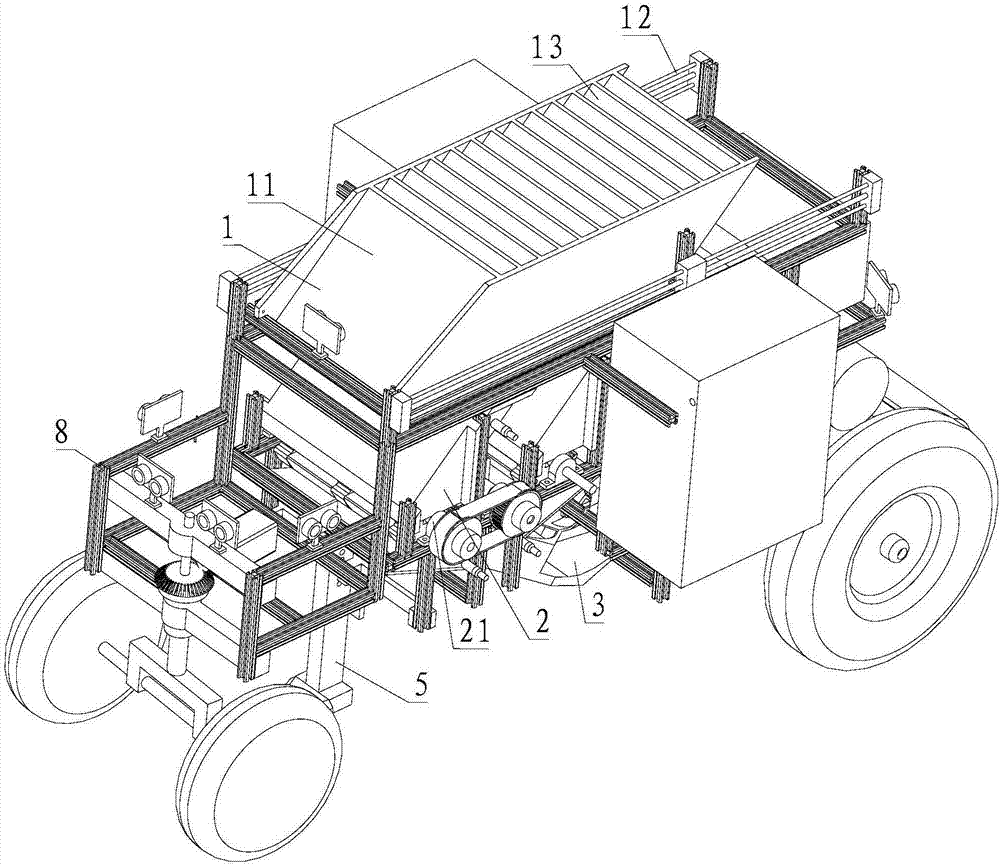

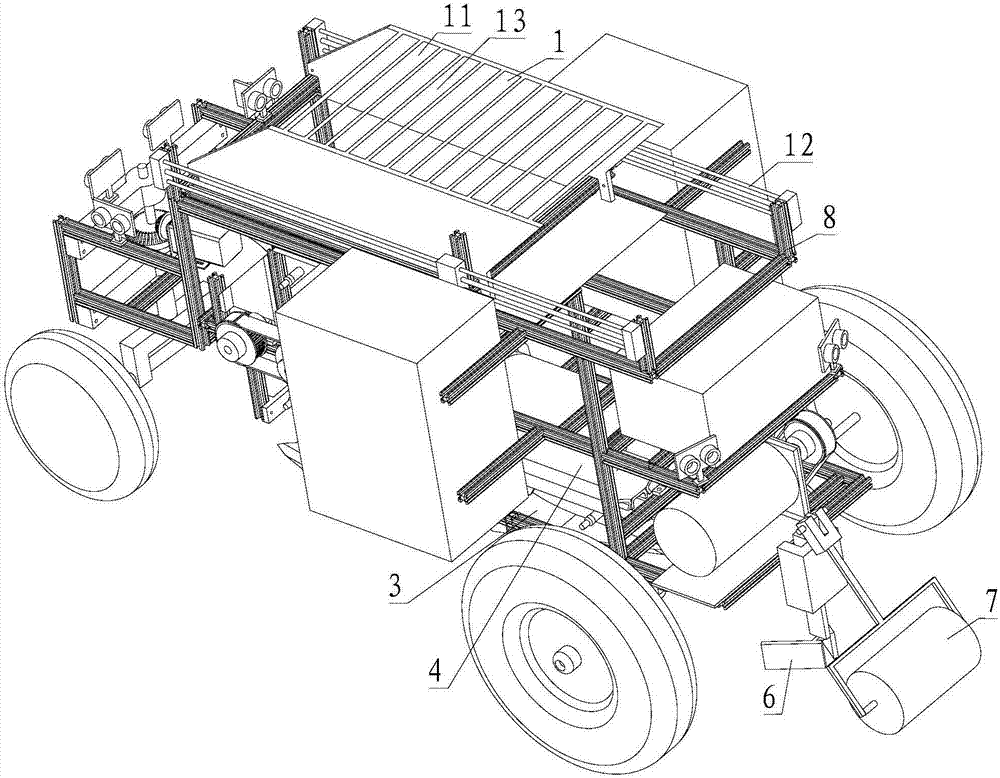

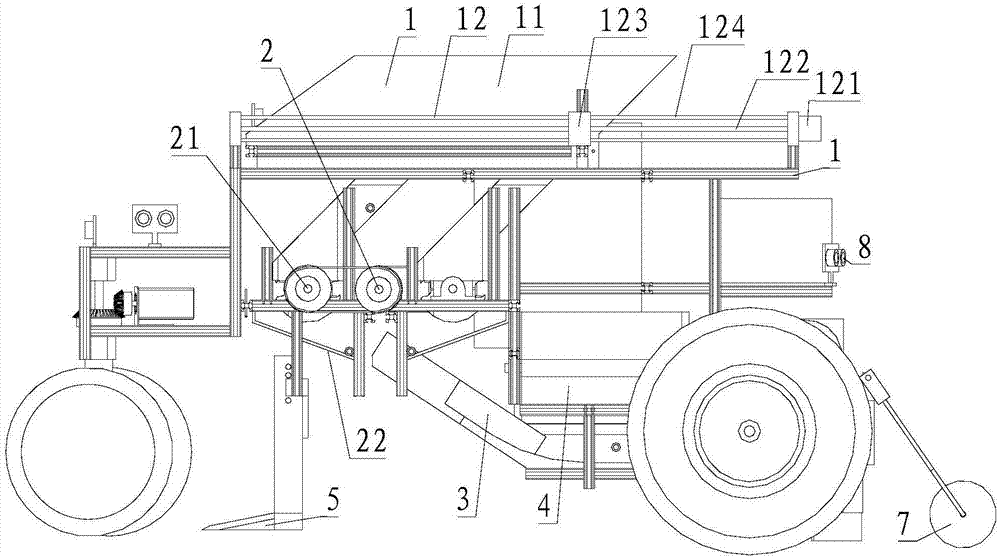

[0058] Please refer to Figure 1 to Figure 10 , Embodiment 1 of the present invention is:

[0059] A giant fungus grass planter, comprising a feeding mechanism 1, a seeding mechanism 2 and a steering mechanism 3, the feeding mechanism 1 includes a seed box 11 and a seed box moving mechanism 12, and the seed box 11 is provided with a plurality of partitions 13. The distance between adjacent partitions 13 is adapted to the width of the Jujuncao seedlings. The seed box moving mechanism 12 drives the seed box 11 to move back and forth along the front and rear directions of the planter. The seed discharge mechanism 2 includes a seeding roller 21 and a seeding motor, the seeding motor drives the seeding roller 21 to rotate, the seeding roller 21 and the partition 13 are arranged perpendicular to the front and rear direction of the planter, and the steering mechanism 3. The upper end is docked with the outlet of the seeding roller 21, and the steering mechanism 3 is used to rotate 9...

Embodiment 2

[0060] Please refer to Figure 1 to Figure 10 , the second embodiment of the present invention is:

[0061] A giant juncao planting machine, on the basis of the first embodiment, the seeding mechanism 2 also includes two oppositely arranged gathering plates 22, the number of the seeding rollers 21 is at least one, and a plurality of the The seeding rollers 21 are arranged in parallel, the distance between the upper ends of the two gathering plates 22 is adapted to the total width of a plurality of seeding rollers 21, and the distance between the lower ends is adapted to the width of the giant Junction grass seedlings.

Embodiment 3

[0062] Please refer to Figure 1 to Figure 10 , Embodiment three of the present invention is:

[0063] A giant fungus planter, on the basis of the first embodiment, the steering mechanism 3 includes a steering section 31 and a guide section 32, and the steering section 31 includes an inclined bottom plate 311, an arc baffle 312 and a fulcrum shaft 313, The inclined bottom plate 311 is inclined from top to bottom. There are two arc baffles 312, which are relatively arranged on the upper surface of the inclined bottom plate 311. The bottom of the fulcrum shaft 313 is fixed on the inclined bottom plate 311. The fulcrum shaft 313 Set close to one of the arc baffles 312; the guide section 32 includes a horizontal bottom plate 321 and a straight baffle 322, one end of the horizontal bottom 321 is connected to the bottom of the inclined bottom 311, and the straight baffle 322 has two , relatively arranged on the upper surface of the horizontal bottom plate 321, one end of the straig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com