Special car for angle steel cleaning

A special vehicle and angle steel technology, applied in the directions of cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of easy sticking to concrete, difficult to clean angle steel, dirty ground, etc. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

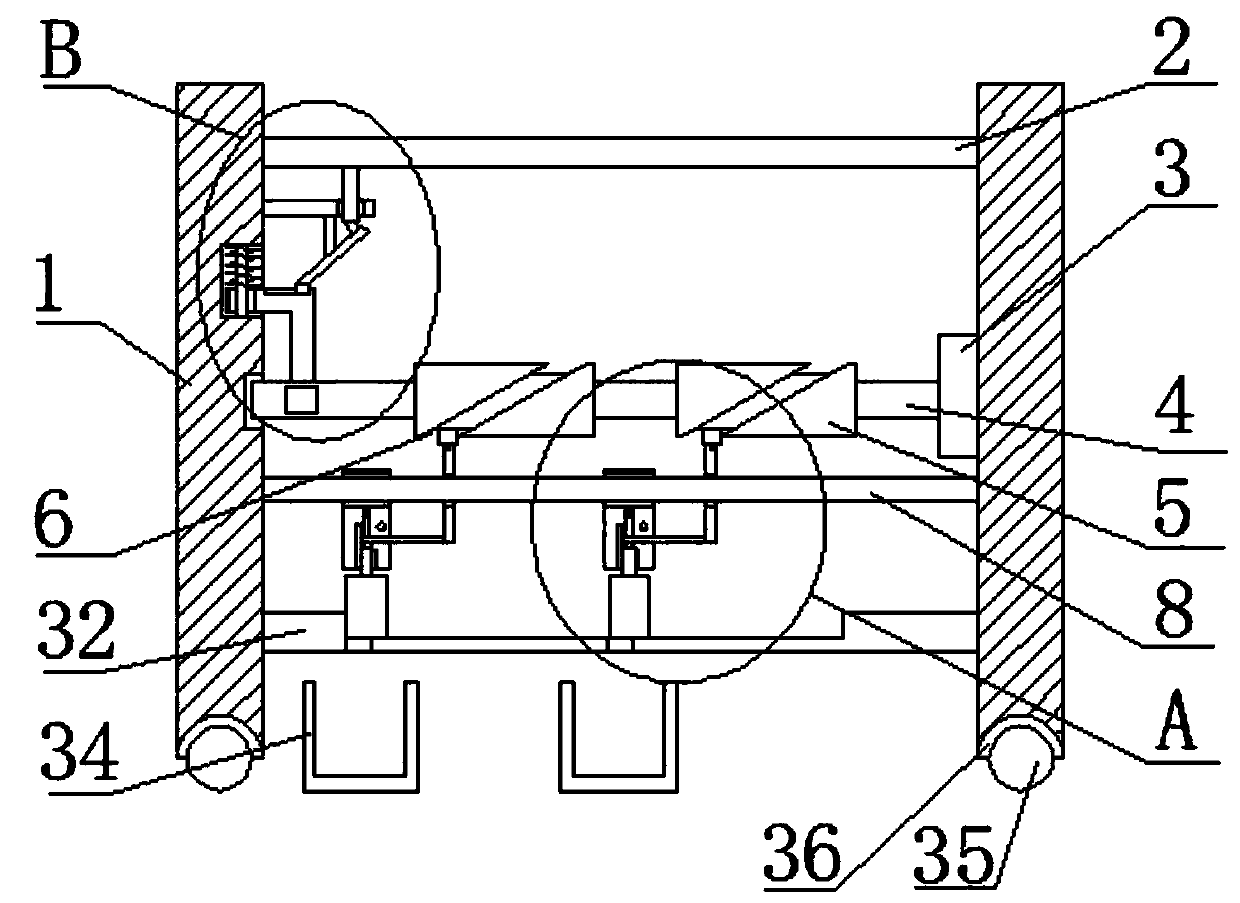

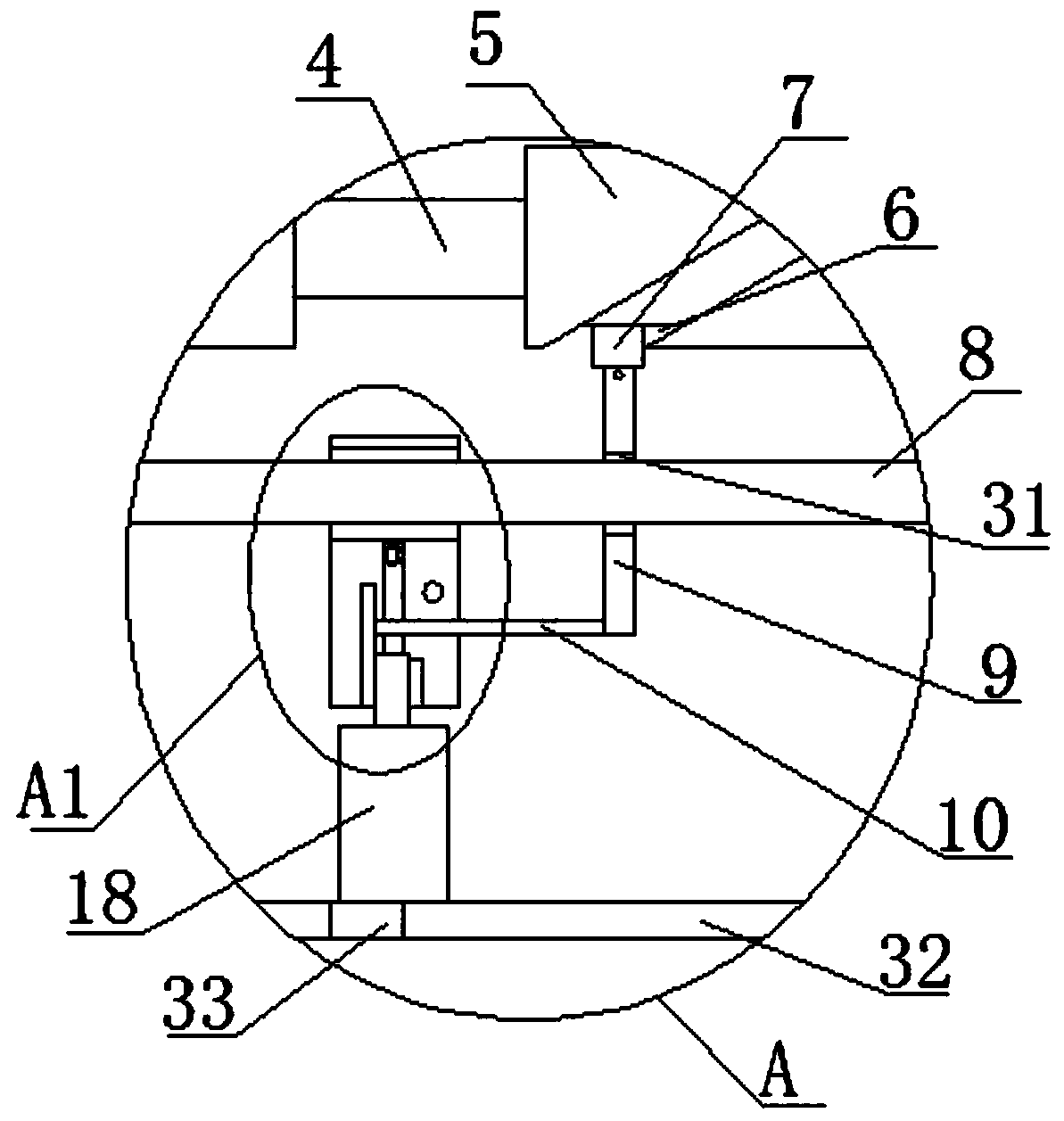

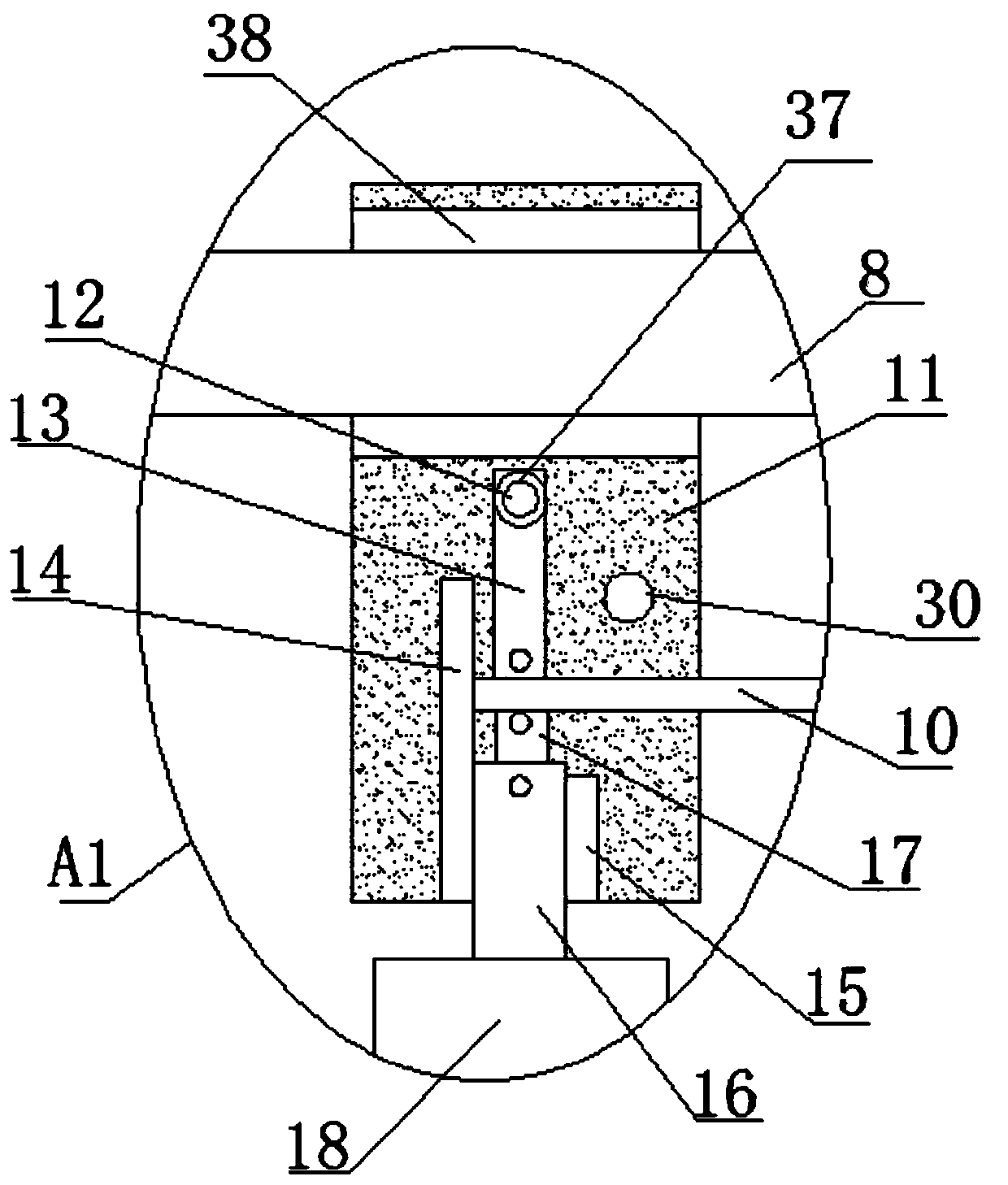

[0028] as attached Figure 1-5 As shown, a special vehicle for angle steel cleaning includes two adjacent support plates 1, the side of the two support plates 1 close to each other is fixedly installed with the same support member 2, and the lower part of the support member 2 is fixedly installed on the The motor 3 on one side of the support plate 1, the output shaft of the motor 3 is fixedly installed with the rotating shaft 4 through the coupling, and the end of the rotating shaft 4 away from the motor 3 is rotated and installed on the corresponding side of the other supporting plate 1. Two cylindrical blocks 5 are fixedly sleeved on the shaft 4, and an annular groove 6 is opened on the cylindrical block 5. The annular groove 6 is arranged obliquely, and a slider 7 is slidably installed in the annular groove 6, and the two support plates 1 are close to each other. The same fixed rod 8 located below the slider 7 is fixedly installed on one side, the fixed rod 8 is movably sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com