Simple hip joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

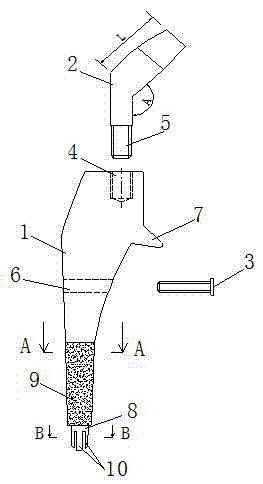

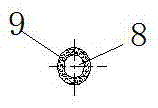

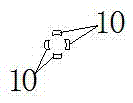

[0031] As attached to the manual Figure 1-3As shown, a simple hip joint includes a femoral stem 1, a femoral neck 2 and a fastening rod 3; the upper end surface of the head of the femoral stem 1 is provided with a threaded hole 4; the lower part of the femoral neck 2 is a positive column as a whole Body shape, the upper part is set as an offset inclined column, and the lower end of the femoral neck 2 is set as a threaded rod 5; the threaded rod 5 is directly connected with the threaded hole 4; The inner interference fit has a fastening rod 3, and a tapered protrusion 7 is provided on the side of the middle part of the femoral stem 1 close to the femoral neck 2; the lower part of the femoral stem 1 consists of a handle body 8 and a The ring-shaped sleeve layer 9 is composed of a multi-level porous material; the end of the handle body at the lower part of the femoral stem 1 protrudes from the ring-shaped sleeve layer 9, and the end of the handle body is set to be coaxial with t...

Embodiment 2

[0042] As attached to the manual Figure 4-5 As shown, a simple hip joint includes a femoral stem 1 and a femoral neck 2; the upper end surface of the head of the femoral stem 1 is provided with a threaded hole 4; Offset inclined column, and the lower end of the femoral neck 2 is set as a threaded rod 5; the threaded rod 5 is directly connected with the threaded hole 4; the middle part of the femoral stem 1 is provided with a tapered protrusion 7 on the side close to the femoral neck 2; The lower part of the femoral stem 1 is composed of a handle body 8 and an annular sheath 9 attached to the outer surface of the handle body 8. The annular sheath 9 is made of a multi-stage porous material; the end of the lower part of the femoral stem 1 protrudes An annular sheath 9, and the end of the handle body is set as two discontinuous annular parts 10 coaxial with the femoral stem 1; the multi-level porous material used in the annular sheath 9 in this embodiment is porous titanium, whic...

Embodiment 3

[0054] As attached to the manual Figure 6-7 As shown, a simple hip joint includes a femoral stem 1, a femoral neck 2 and a fastening rod 3; the upper end surface of the head of the femoral stem 1 is provided with a mounting hole 4; the lower part of the femoral neck 2 is a positive cylinder shape, the upper part is set as an offset inclined column; the lower part of the femoral neck 2 is directly installed in the installation hole 4 through interference fit; the middle part of the femoral stem 1 is provided with a hole 6, and the interference fit in the hole 6 is fastened Insertion rod 3; the lower part of its femoral stem 1 is composed of a handle body 8 and an annular sheath 9 attached to the outer surface of the handle body 8, and the annular sheath 9 is made of a multi-stage hole material; the lower part of its femoral stem 1 The end of the body protrudes from the annular sheath 9, and the end of the handle body is set as a discontinuous annular part 10 coaxial with the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com