Crane control method based on input shaping technology

A technology of input shaping and control methods, applied in the field of crane control, can solve the problems of reducing production efficiency and increasing work costs, and achieve the effects of improving work efficiency, easy implementation, and accurate and effective control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is described in detail:

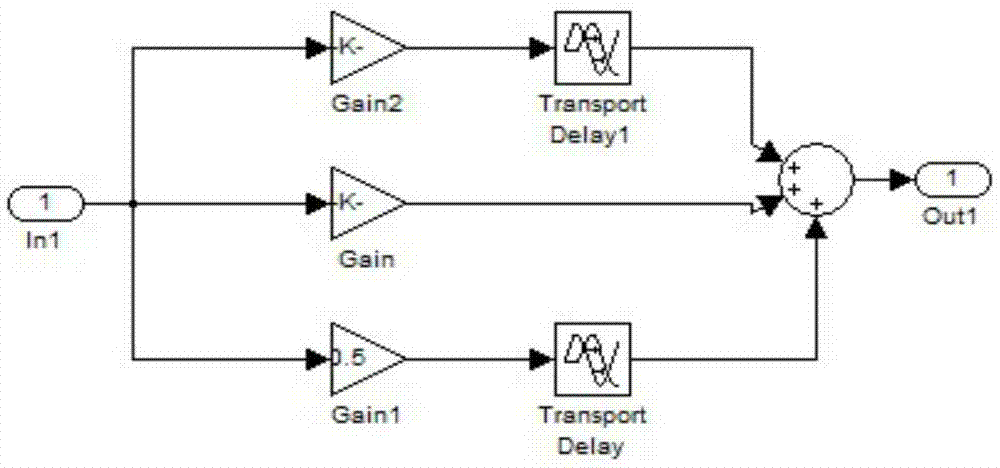

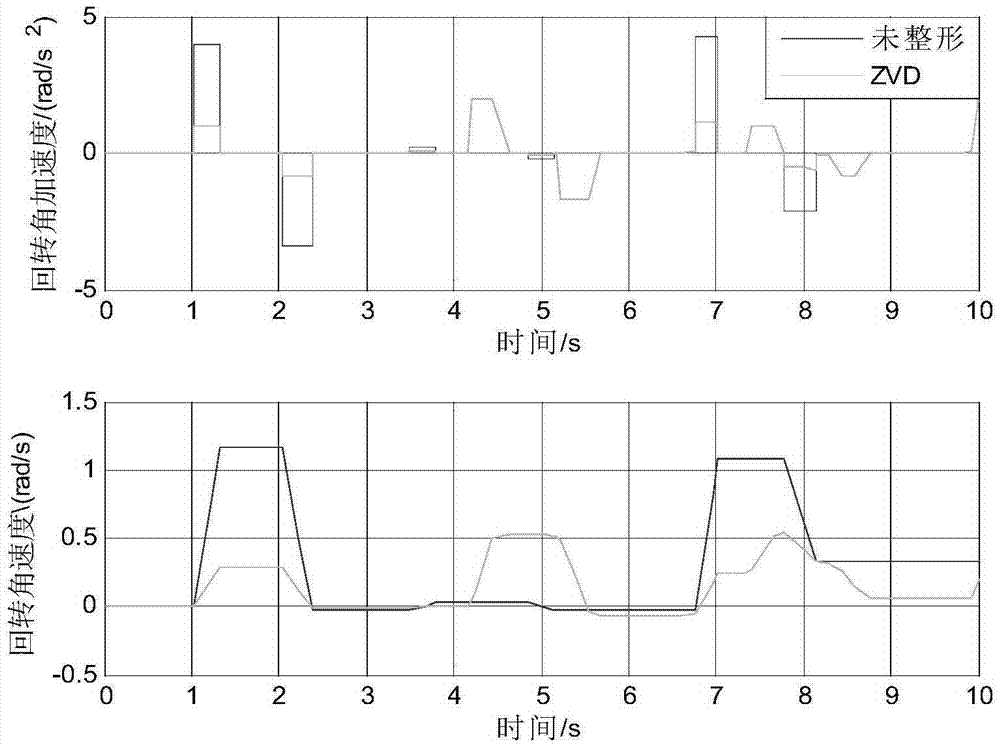

[0020] A crane control method based on input shaping technology, characterized in that by analyzing and solving the mathematical model of the crane based on the Lagrange dynamic equation, aiming at the error existing in the modeling of the actual system, using zero oscillation zero differential (ZVD) input shaping The controller is used to control the crane, and the designed zero-vibration and zero-derivative (ZVD) input shaper for the crane is simulated and verified.

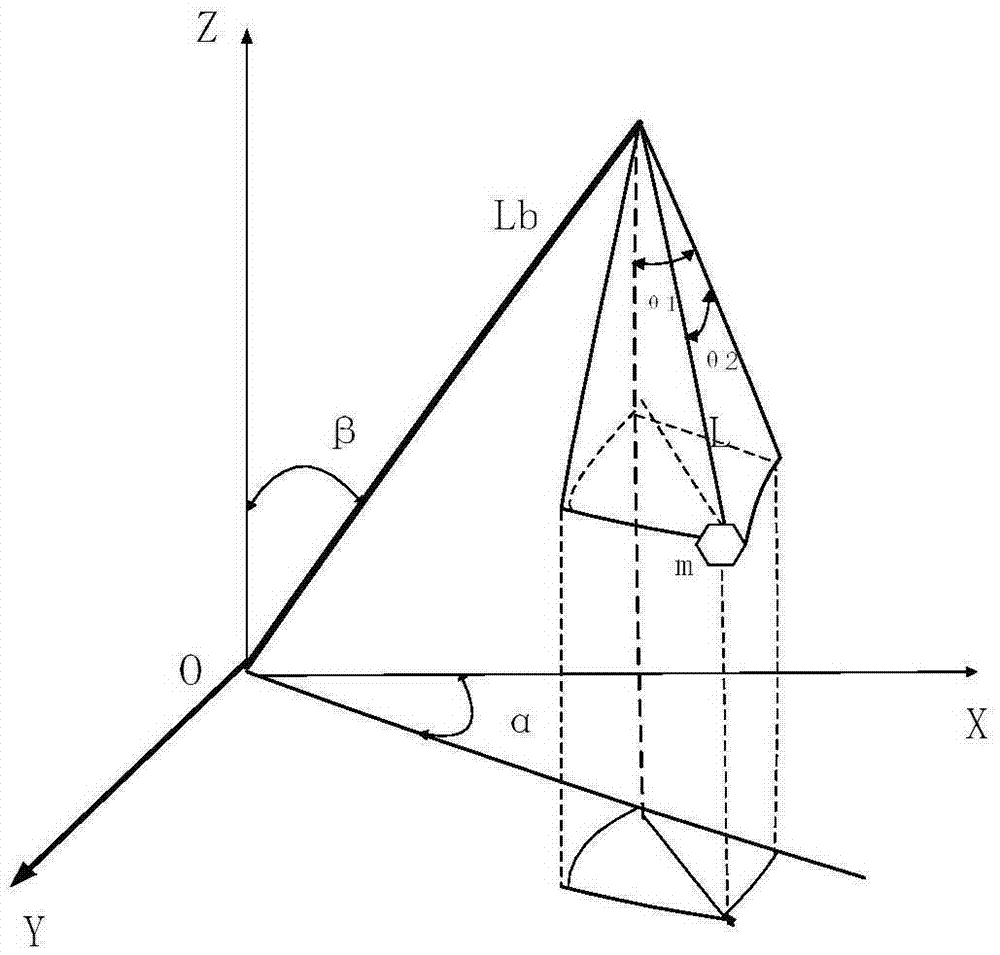

[0021] combine figure 1 In the physical model of the crane, the residual swing of the load can be expressed as the swing angle θ in the plane of the boom 1 and the swing angle θ out of the plane of the boom 2 . Let the mass of the load be m and the length of the boom be L B , the length of the rope is L, the angle between the plane of the boom and the horizontal axis of the crane (that is, the X axis) is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com