Filler reaction tower

A technology of packed reaction tower and reaction tower, which is applied in special compound water treatment, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of insufficient gas-liquid contact, waste of resources, low catalytic efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below with reference to the accompanying drawings and examples.

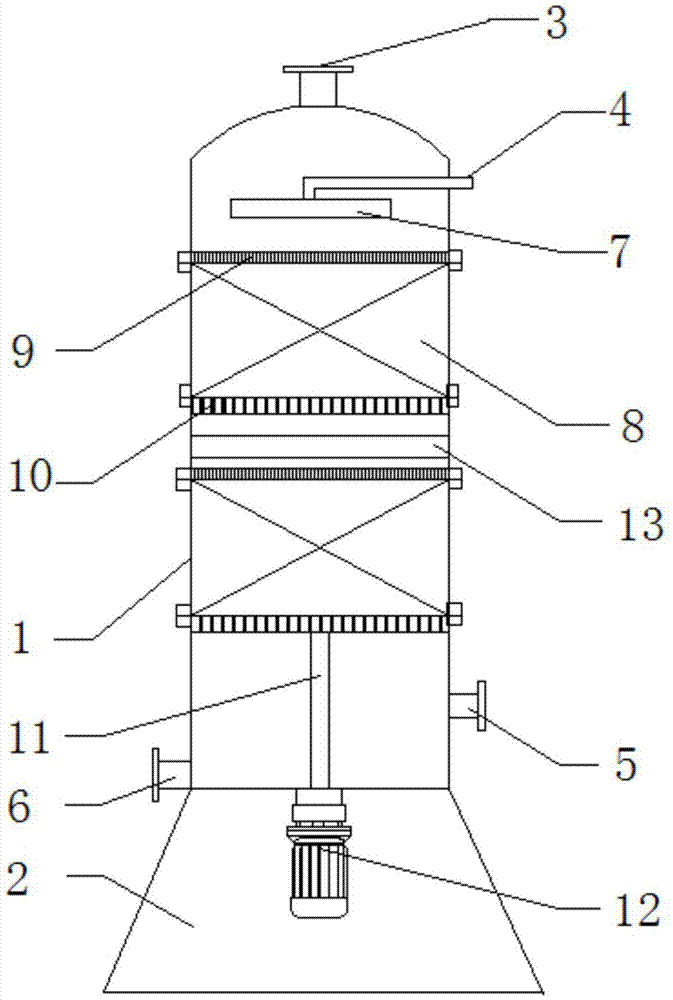

[0013] A packed reaction tower, comprising a tower body 1 and a skirt 2, the skirt 2 is arranged at the lower part of the tower body 1, the top of the tower body 1 is provided with a gas outlet 3, the top side wall is provided with a liquid inlet 4, and the bottom The side wall is provided with an air inlet 5 and a liquid outlet 6, and the inside of the tower body 1 is provided with a liquid distributor 7 and a packing layer 8, and the liquid distributor 7 communicates with the liquid inlet 4 and is arranged on the packing layer. 8, the upper surface of the packing layer 8 is fixed with a pressure plate 9, and the lower surface is fixed with a support grid 10, and the support grid 10 is power-connected with the reduction motor 12 in the skirt 2 through the rotating shaft 11.

[0014] In order to further improve the catalytic efficiency, the packing layer 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com