An edge stretching machine controlling device, a method of detecting edge stretching wheels winded with molten glass and a system

A control device and edge pulling machine technology, applied in the direction of measuring devices, glass forming, glass forming, etc., can solve the problems of long time consumption, low accident handling efficiency, equipment damage, etc., to save operation steps and improve accident handling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

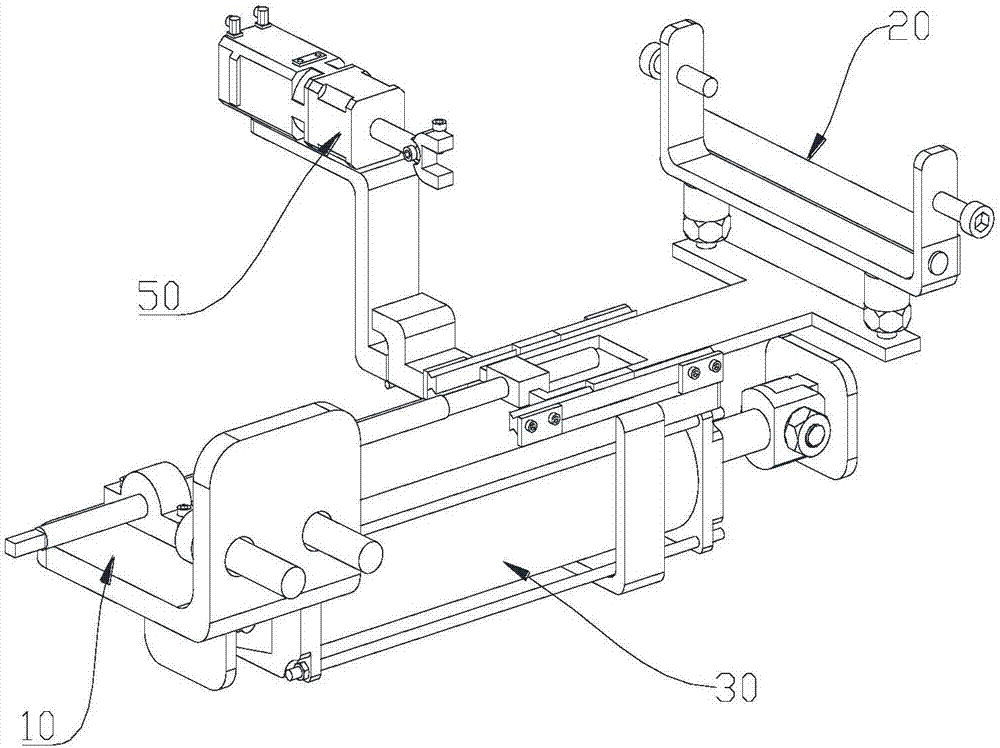

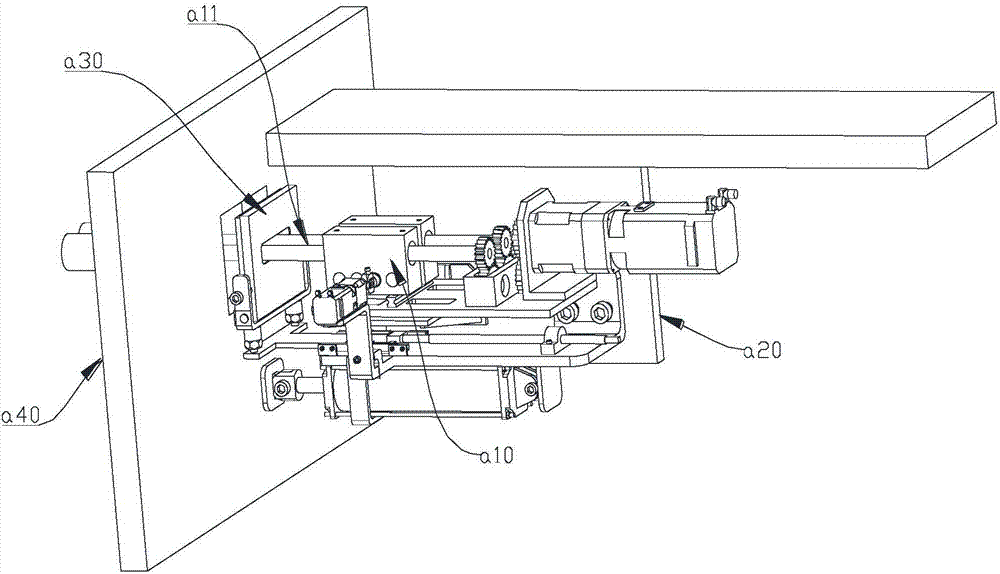

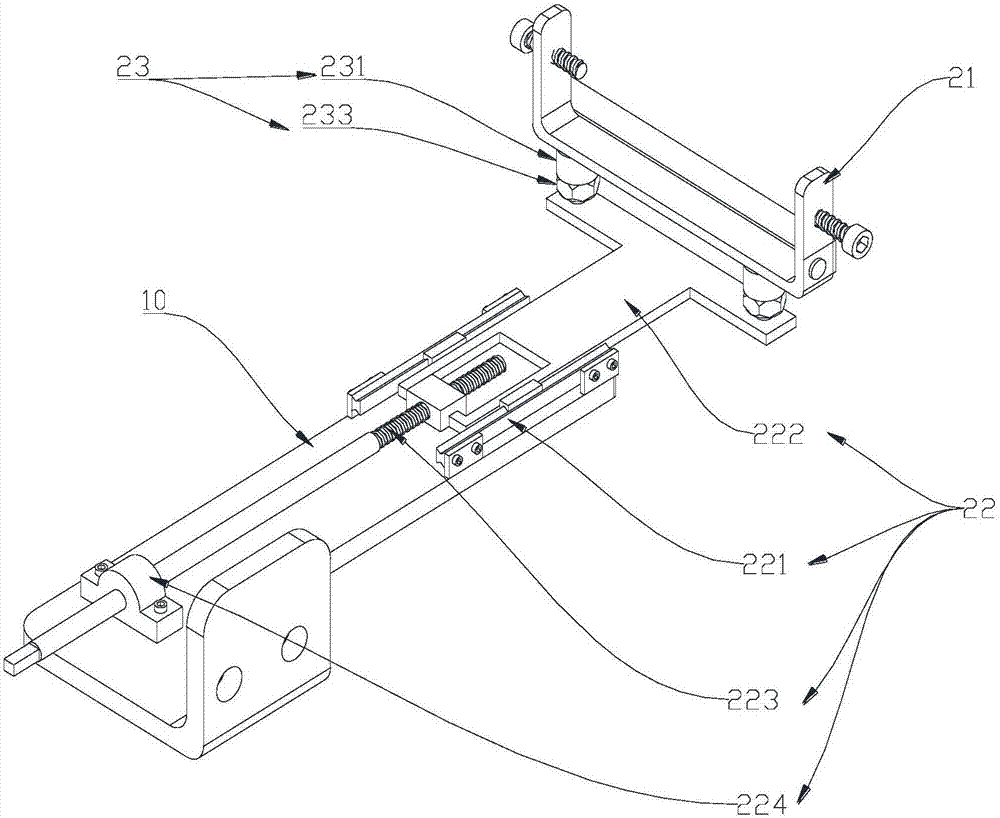

[0067] Such as figure 1 with figure 2 As shown, an embodiment of the present invention proposes an edge pulling machine control device, which includes:

[0068] The fixed bracket 10 is used to connect with the edge pulling machine a10 or the edge pulling machine hanger a20; specifically, the fixing bracket can be prepared from a steel plate with a thickness of 10-15mm to meet the requirements of weight support, and the connection method can be fixed by bolts connect;

[0069] The front fender locking mechanism 20 is used for fixing the front fender a30 , and the front fender locking mechanism 20 is arranged on the fixing bracket 10 .

[0070] Among them, the front baffle a30 is used as a joint sealing part between the edge pulling machine a10 and the mouth of the shaping furnace a40. In the liquid crystal glass production and molding process system, the edge pulling shaft a11 extends from the opening on the front baffle a30 into the shaping furnace a40 internal.

[0071] ...

Embodiment 2

[0089] Embodiment 2 of the present invention provides a method for detecting molten glass wrapped around the edge pulley of the edge puller by the control device of the edge puller, which is characterized in that it includes:

[0090] Identify the output torque value of the drive motor on the edge pulling machine that outputs power for the edge pulling shaft;

[0091] According to the output torque value, it is judged whether the edge pulling wheel of the edge pulling machine is wound around the molten glass;

[0092] If the output torque value is greater than the set threshold, it is judged that the edge puller of the edge puller is wrapped around the molten glass;

[0093] The specific threshold can be set according to the actual situation, for example, a range value is set at 0.8-1.5Nm.

[0094] Specifically, if the output torque value is less than the set threshold, it is determined that the edge pulley of the edge puller is not wrapped with molten glass.

[0095] Compar...

Embodiment 3

[0097] A production and molding process system for liquid crystal glass, characterized in that it includes:

[0098] Shaping furnace;

[0099] Edge pulling machine guide rail;

[0100] An edge-drawing machine hanger, which is slidably connected to the guide rail of the edge-drawing machine;

[0101] The edge pulling machine is arranged on the hanging frame of the edge pulling machine;

[0102] Edge pulling machine control device, including:

[0103] Fixed bracket, used to connect with edge pulling machine or edge pulling machine hanger;

[0104] The front baffle locking mechanism is used to fix the front baffle, and the front baffle locking mechanism is arranged on the fixing bracket;

[0105] The fixing bracket is fixed on the edge pulling machine or the hanging frame of the edge pulling machine.

[0106] In the technical solution provided by the embodiment of the present invention, the front baffle locking mechanism can be fixed on the edge pulling machine or the edge pul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com