Measurement method for local surface resistance of contaminated insulator

A technology of surface resistance and measurement method, applied in the direction of measurement device, measurement of electrical variables, measurement of resistance/reactance/impedance, etc., can solve problems such as affecting measurement accuracy, and achieve elimination of contact resistance, simple operation, and overcoming large dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

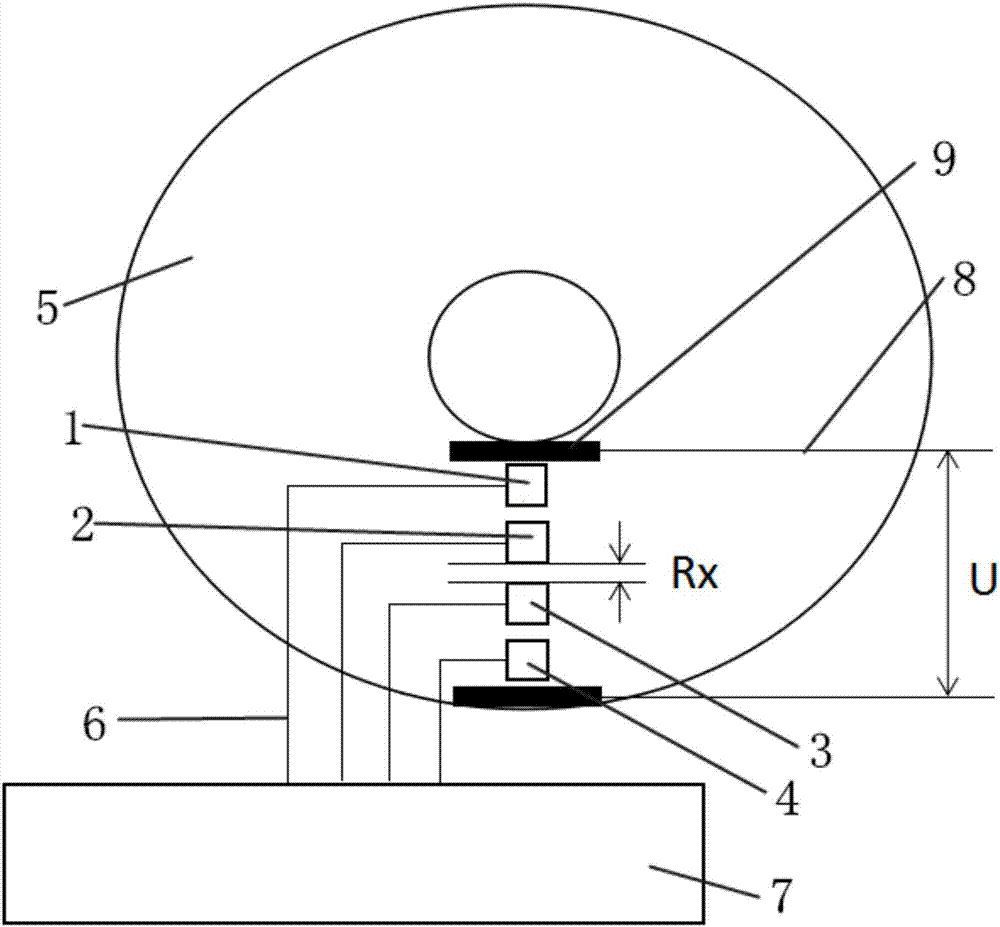

Embodiment 1

[0039] The sticking area of the aluminum foil tapes 1, 2, 3, 4 on the polluted insulator 5 to be tested is an arc edge with the same radius from the center of the polluted insulator 5 to be tested.

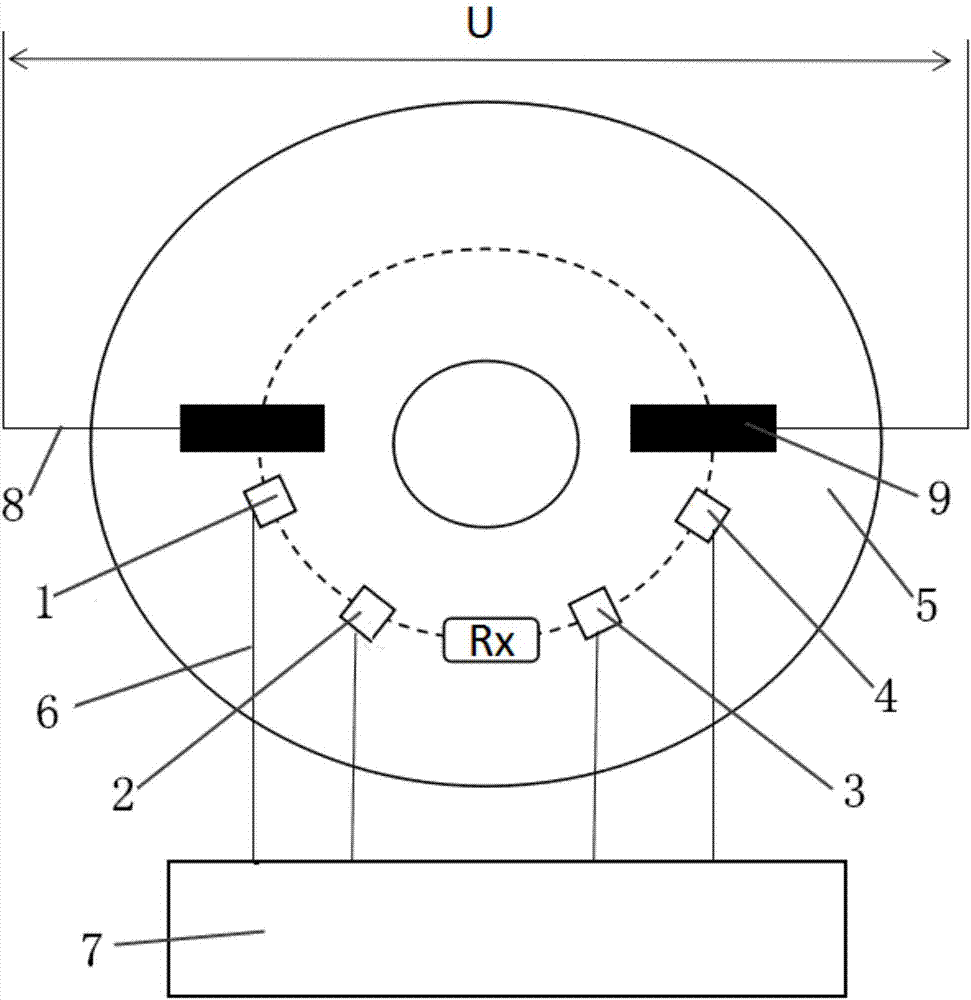

Embodiment 2

[0041] The sticking area of the aluminum foil tapes 1, 2, 3, 4 on the polluted insulator 5 to be tested is a diameter at the center of the polluted insulator 5 to be tested.

[0042] In the above two embodiments, the partial division methods of the aluminum foil tapes 1, 2, 3, and 4 to the polluted insulator under test can ensure the stability of the current flow when the overall pressure is applied to the polluted insulator under test.

[0043] In the above-mentioned embodiment 1, when a voltage is applied to the polluted insulator 5 as a whole, the two ends of the applied voltage should preferably be the same arc edges pasted on the insulator 5 by the aluminum foil tape 1, 2, 3, and 4, so as to ensure the continuity of the current. shortest path.

[0044] In the above-mentioned embodiment 2, when a voltage is applied to the measured dirty insulator 5 as a whole, the two ends of the applied voltage should preferably be the two ends of the same diameter pasted on the tested in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com