An integrated alignment and calibration system

An integrated, box-shaped technology, which is applied in the direction of microlithography exposure equipment, instruments, photoplate making process of pattern surface, etc., can solve the problem that the processing accuracy and motion accuracy cannot be absolutely accurate, and the relative position of CCD camera and suction cup camera Inaccurate, inaccurate graphic exposure and other problems, to achieve the effect of improving calibration work efficiency, improving alignment work efficiency, and improving calibration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

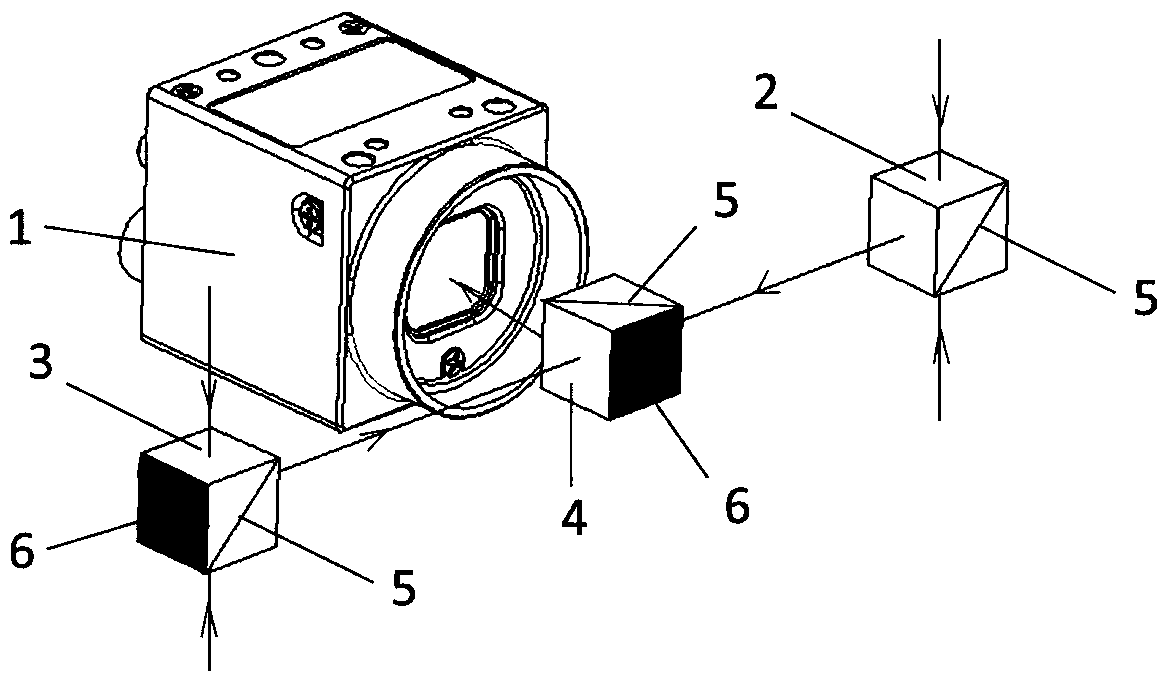

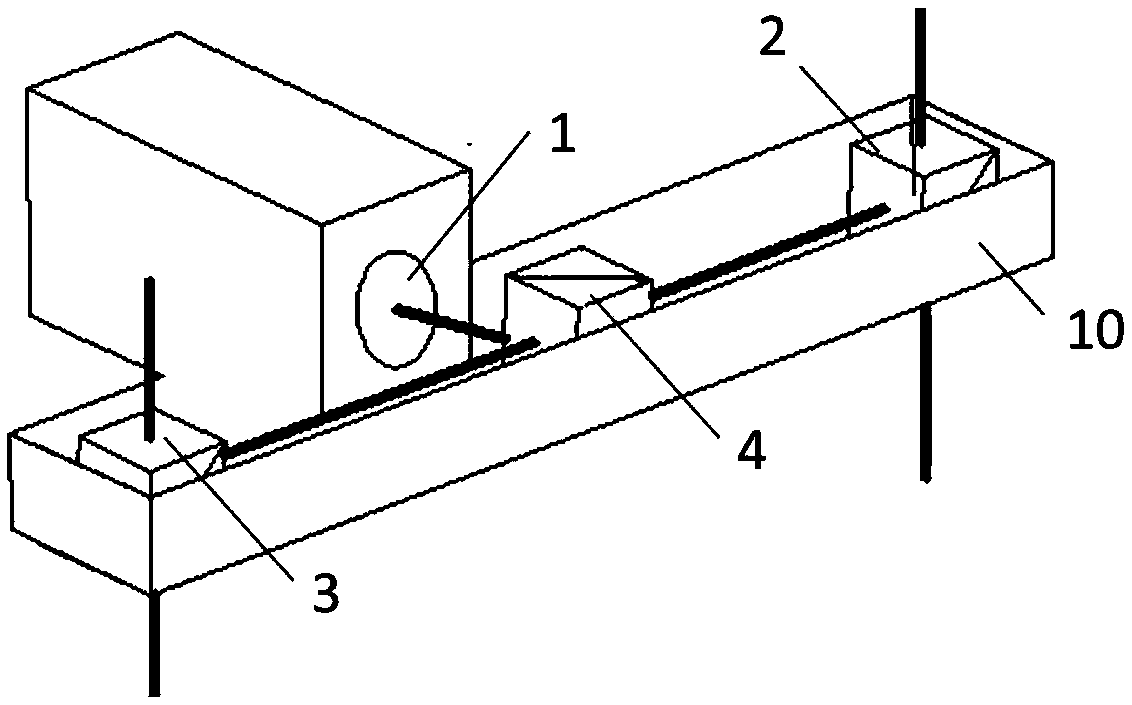

[0028] Embodiment 1 Alignment and calibration integrated system

[0029] Such as Figure 1-Figure 4 The alignment and calibration integrated system of the invention is illustrated as shown.

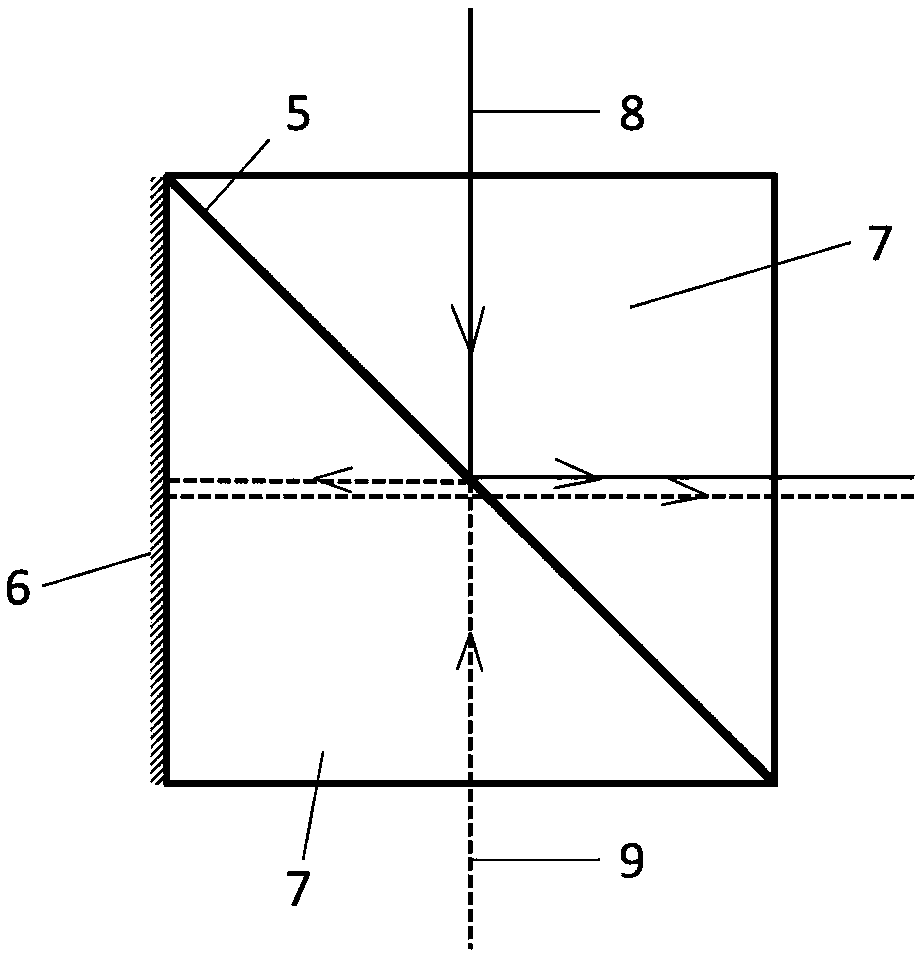

[0030] The alignment and calibration integrated system includes a CCD camera 1 and an optical path assembly. The CCD camera 1 is set horizontally, and the lens of the CCD camera 1 faces the horizontal direction. Prism assembly 4, each group of prism assemblies comprises 2 oppositely arranged triangular prisms 7, and said triangular prism 7 is a triangular prism structure whose cross section is an isosceles right triangle, and the faces where the hypotenuses of 2 triangular prisms 7 of each group of prism assemblies are opposite Close to the setting, a semi-transparent and semi-reflective film 5 is arranged between the two sides; 3 groups of prism assemblies are arranged in a straight line, wherein the middle group of prism assemblies 4 is located directly in front of the lens of the CCD ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com