Processing method of forged aluminum alloy two-piece car wheel rim

A processing method and two-piece technology, applied in the field of special forging, can solve problems affecting driving safety and air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

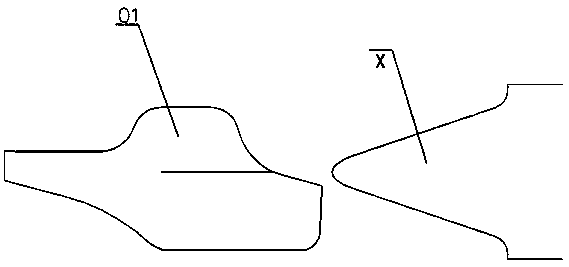

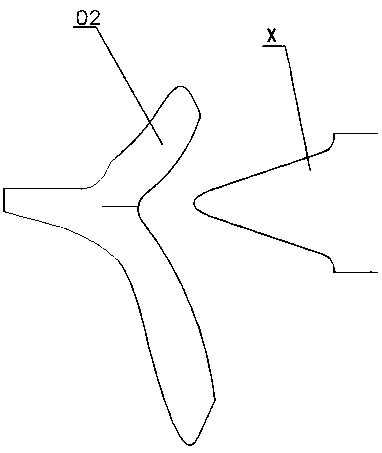

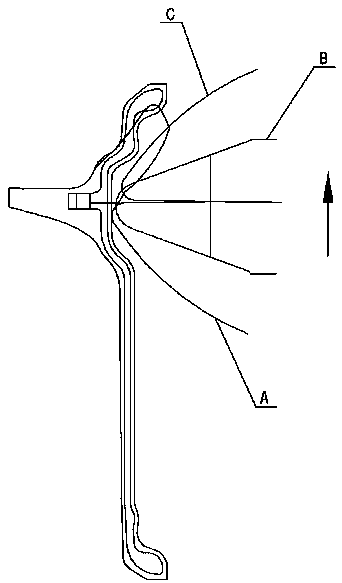

[0016] The invention relates to a processing method for forging aluminum alloy two-piece car wheel rims, such as figure 1 — Figure 4 shown, including the following steps:

[0017] ①. Preheating: Take a piece of aluminum rod, and use a heating furnace to preheat it to above 460°C, generally not exceeding 500°C;

[0018] ②, Pre-pressing: Forging and pressing the preheated aluminum rods through a 2000T hydraulic press, forging and pressing into a cake-shaped rough billet;

[0019] ③ Forming forging: place the cake-shaped rough blank in the forming forging die accurately by the manipulator, and carry out die forging with a rotary forging hydraulic press of about 8000T to obtain a rough blank with a thin center and thick sides;

[0020] ④, Punching and shaping: the obtained blank is shaped under a 630T hydraulic press through a shaping die, and at the same time, the excess waste in the middle is washed away, and finally a ring forging 01 with a slightly thinner middle and thicke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com