Sweet potato wine preparation device

A preparation device, sweet potato technology, applied in the preparation of alcoholic beverages and other directions, can solve the problems of high labor intensity, complex operation procedures, etc., and achieve the effects of low investment and operation costs, simple overall structure, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

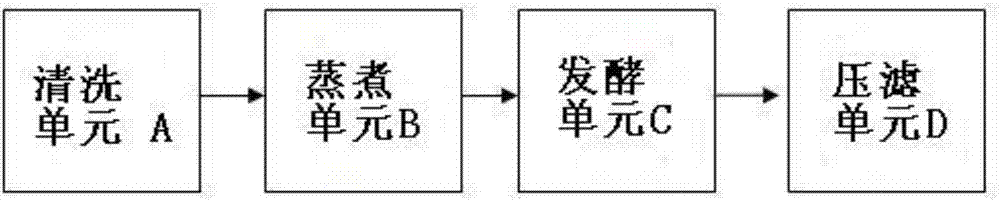

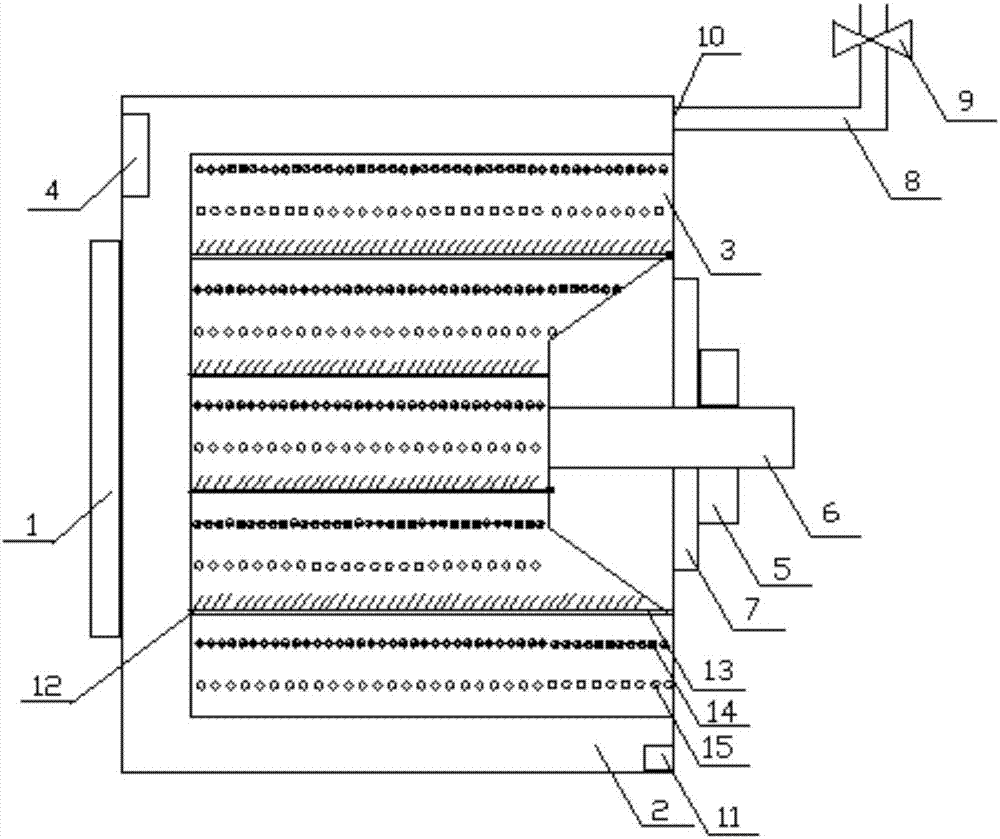

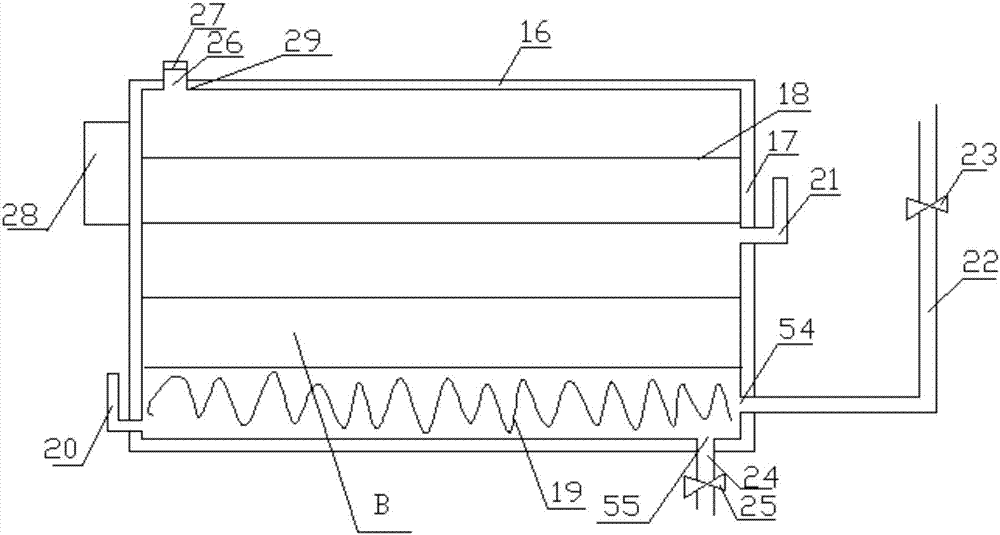

[0036] The main structure of the sweet potato wine preparation device involved in this embodiment includes a cleaning unit A, a cooking unit B, a fermentation unit C, and a filter press unit D, and the functional units are composed of a conveyor belt, a transfer device, or an electromechanical connection. figure 1 In the integrated device shown, the main structure of the cleaning unit A includes a material inlet and outlet 1, an outer barrel 2, a drum 3, a controller 4, a first motor 5, a drum shaft 6, a bearing seat 7, and a first water inlet pipe 8 With the first water inlet valve 9, the front side of the outer barrel 2 of the vertically arranged cavity structure is provided with a material inlet and outlet 1, and the cavity of the outer barrel 2 is provided with a rotatable drum 3 for washing, cylindrical or prismatic The axis of the drum 3 of the structure is parallel to the horizontal ground. A drum shaft 6 is arranged at the center of the rear side of the drum 3. The drum...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that the axis of the cylindrical drum 3 of the cleaning unit A forms an acute angle with the horizontal ground, and the inclined drum 3 is arranged to help increase the tumbling effect of the sweet potatoes as the raw material, making cleaning easier thorough.

Embodiment 3

[0050] The difference between this embodiment and Embodiment 1 is: the heater 19 of the cooking unit B is arranged on the left and right sides or any one side of the box body 16, a water tank is arranged below the heater 19, and the second water inlet pipe 22 It is connected with the water tank and can effectively reduce the temperature difference between the multi-layer trays 22, so that the raw material sweet potatoes are heated evenly and have the same maturity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com