A method and device for improving the utilization rate of zinc powder in zinc sulfate liquid purification

A liquid purification, zinc sulfate technology, applied in the field of metallurgy and chemical industry, can solve the problems affecting the utilization rate of zinc powder, less zinc powder, etc., and achieve the effects of improving the utilization rate of zinc powder, high work efficiency, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

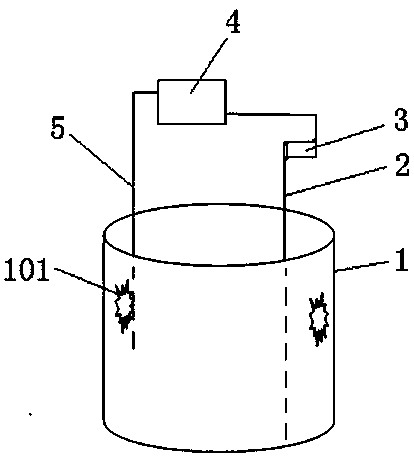

[0027] A method for improving the utilization rate of zinc powder when zinc sulfate liquid is purified at low temperature, is characterized in that it comprises the following steps:

[0028] 1) Add zinc powder in an amount of 1g / L to the purification reaction tank 1, so that the zinc powder and the impurity ions in the zinc sulfate solution undergo a replacement reaction, and the reaction time is 1 hour;

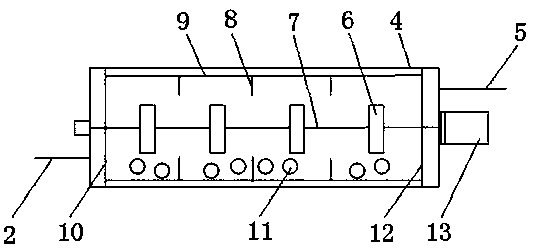

[0029] 2) Send the reaction mixture in step 1) into the cavity of cylinder 4 through pump 3, feed pipe 2, and inlet. The flow rate of the reaction mixture and the volume ratio of the purified reaction tank are: 3:1 (m 3 / h:m 3 ), control the rotating speed of the stirring shaft 7 in the cavity of the cylinder body 4 to be 2900 rev / min, make the reaction mixture react in the cavity of the cylinder body 4 for 6 seconds, and let the cladding be in the rotating turbine 6, friction parts 11, separators 8. Under the action of the wear-resistant lining plate 9, it is separated fro...

Embodiment 2

[0033] A method for improving the utilization rate of zinc powder when zinc sulfate liquid is purified at high temperature is characterized in that it comprises the following steps:

[0034] 1) Add zinc powder in an amount of 4g / L to the purification reaction tank 1, so that the zinc powder and the impurity ions in the zinc sulfate solution undergo a replacement reaction, and the reaction time is 2.5 hours;

[0035] 2) Send the reaction mixture in step 1) into the cavity of the cylinder 4 through the pump 3, feed pipe 2, and inlet. The flow rate of the reaction mixture and the volume ratio of the purified reaction tank are: 6:1 (m 3 / h:m 3), control the rotating speed of the stirring shaft 7 in the cavity of the cylinder body 4 to be 3200 rpm, make the reaction mixture react in the cavity of the cylinder body 4 for 15 seconds, and let the cladding be in the rotating turbine 6, the friction piece 11, the separator 8. Under the action of the wear-resistant liner 9, it will be s...

Embodiment 3

[0039] A method for improving the utilization rate of zinc powder when zinc sulfate liquid is purified at high temperature is characterized in that it comprises the following steps:

[0040] 1) Add zinc powder in an amount of 2g / L to the purification reaction tank 1, so that the zinc powder and the impurity ions in the zinc sulfate solution undergo a replacement reaction, and the reaction time is 2 hours;

[0041] 2) Send the reaction mixture in step 1) into the cavity of cylinder 4 through pump 3, feed pipe 2, and inlet. The flow rate of the reaction mixture and the volume ratio of the purified reaction tank are: 4:1 (m 3 / h:m 3 ), control the rotating speed of the stirring shaft 7 in the cavity of the cylinder body 4 to be 3000 rev / min, make the reaction mixture react in the cavity of the cylinder body 4 for 10 seconds, and let the cladding be in the rotating turbine 6, the friction member 11, the separator 8. Under the action of the wear-resistant liner 9, it will be separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com