Optimization and recombination method for well network of in-situ leaching uranium mining

A technology of in-situ leaching for uranium mining and well pattern, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., and can solve problems such as the impact of uranium resource leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In the method for optimizing and reorganizing in-situ leaching uranium well pattern according to the present invention, when the uranium concentration of the leaching liquid of the leaching unit in the well site mining area is 6-10 mg / L, the position of the pumping liquid well is adjusted; the boundary of the mining area is the injection liquid If the well is not adjusted to be an extraction well, it is ensured that all the periphery of the mining area are injection wells;

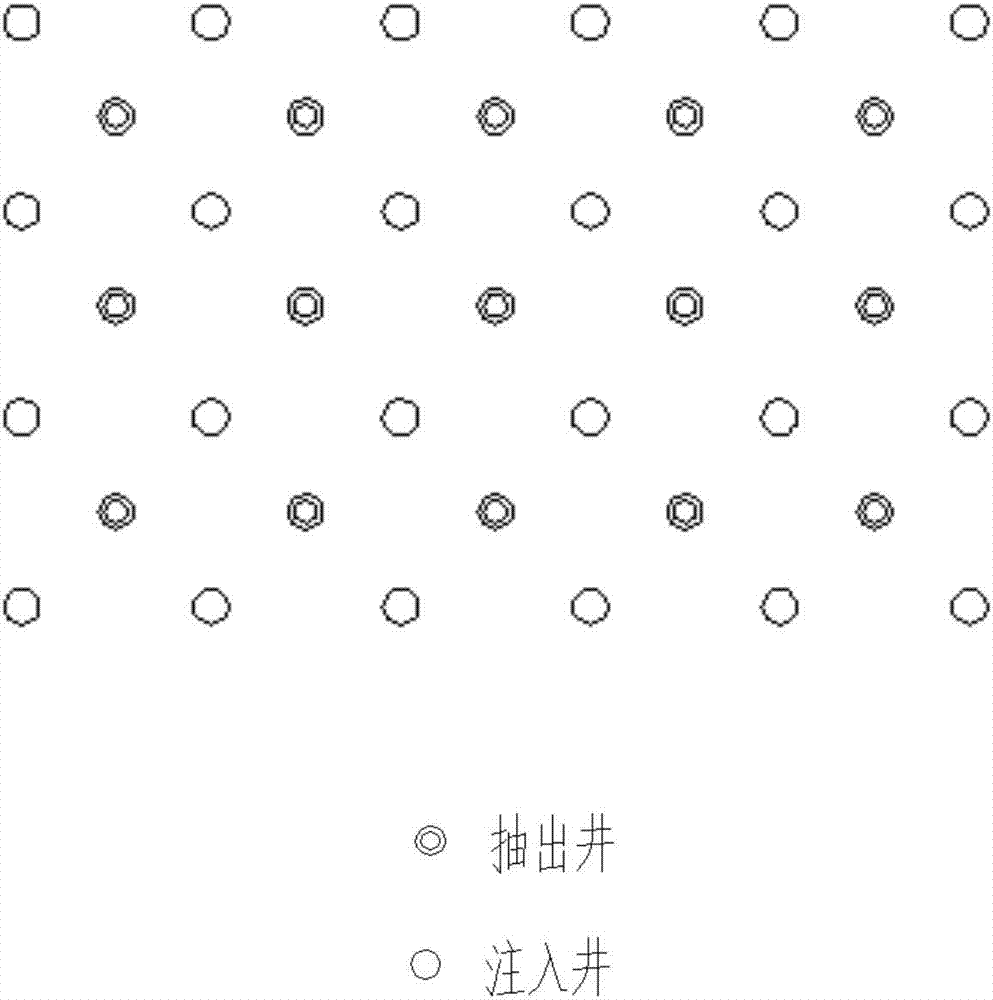

[0029] like figure 1 When the well type shown is five-point type, the adjacent extraction wells are connected in a straight line, and the adjacent injection wells are connected in a straight line, the original extraction well is changed to an injection well, and the original injection well is changed to an extraction well, and the adjusted well type is not yet five-point type, such as figure 2 shown.

[0030] The size of the extraction well is 148×10mm, and the size of the injection well is 148×1...

Embodiment 2

[0035] In the method for optimizing and reorganizing in-situ leaching uranium well pattern according to the present invention, when the uranium concentration of the leaching liquid of the leaching unit in the well site mining area is 6-10 mg / L, the position of the pumping liquid well is adjusted; the boundary of the mining area is the injection liquid If the well is not adjusted to be an extraction well, it is ensured that all the periphery of the mining area are injection wells;

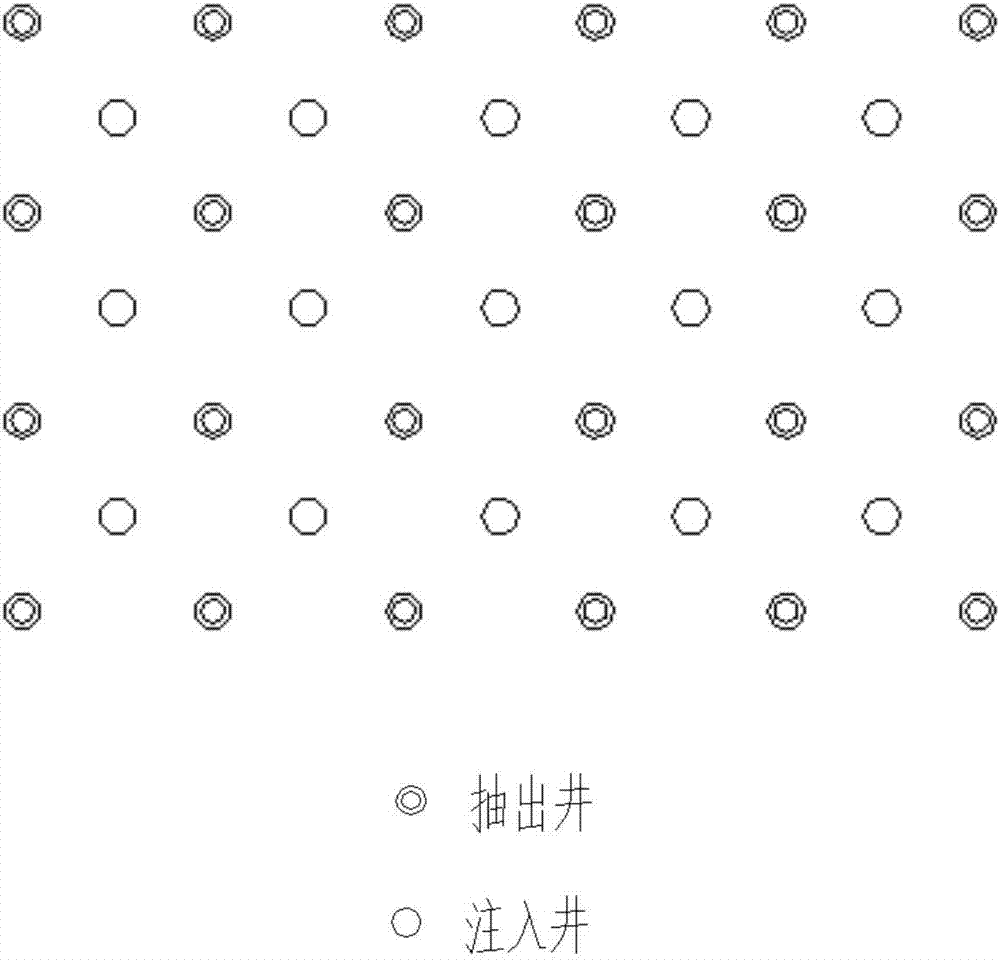

[0036] like image 3 As shown, when the well type is a seven-point type, the extraction wells are connected by a line, and two injection wells are spaced between every two extraction wells, and they are translated in the same direction along the straight line. The injection well is changed to the extraction well, and the adjusted well type is still the seven-point type; Figure 4 shown.

[0037] The size of the extraction well is 148×10mm, and the size of the injection well is 148×10mm.

[0038] ...

Embodiment 3

[0042] In the method for optimizing and reorganizing in-situ leaching uranium well pattern according to the present invention, when the uranium concentration of the leaching liquid of the leaching unit in the well site mining area is 6-10 mg / L, the position of the pumping liquid well is adjusted; the boundary of the mining area is the injection liquid If the well is not adjusted to be an extraction well, it is ensured that all the periphery of the mining area are injection wells;

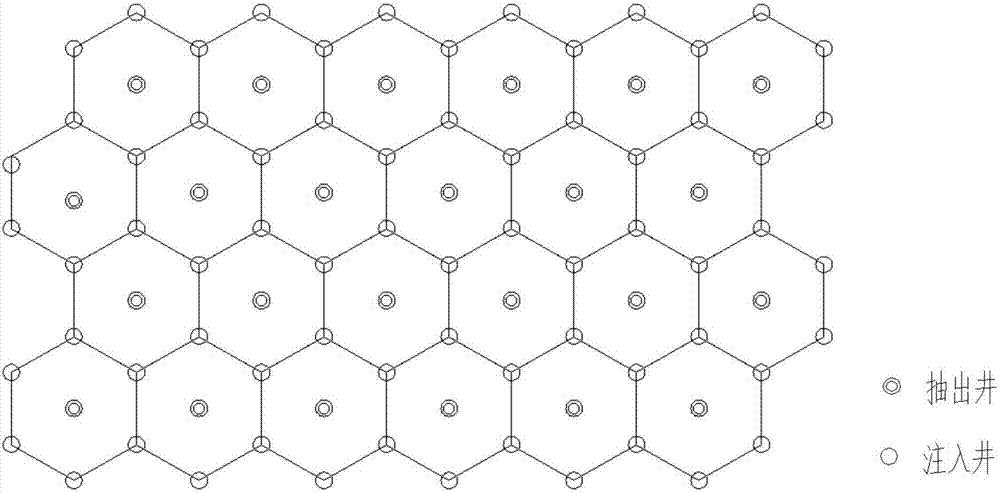

[0043] like Figure 5 As shown, when the well type is determinant type I, the extraction wells are connected, the injection wells are connected, the extraction wells are translated in the same direction to the adjacent injection wells, the original extraction wells are changed to injection wells, and the original translation wells are changed to injection wells. Change the original injection well to the extraction well, and ensure that the adjusted well type is still the determinant type I, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com