Method for preparing rock core for shale experiments

A core and shale technology, applied in the preparation of test samples, etc., can solve the problems of error in experimental results, inability to simulate the characteristics of shale pore roar, etc., and achieve the effect of accurate experimental results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0042] It should be noted that the test core prepared in the first embodiment of the present invention can be used in a shale micro-fracture plugging experiment, and this experiment can truly evaluate the plugging effect of the plugging agent on shale micro-fractures. The concrete steps of rock core preparation method of the present invention are as follows:

[0043] (1) if figure 1 As shown, the core used in the present invention is real formation shale or outcrop rock. Adopt dry method or liquid nitrogen cooling method to drill rock core column 1, the diameter of rock core column 1 is preferably 20~30mm (particularly

[0044] 25 mm), the ratio of the length to the diameter of the core column 1 is preferably 0.2-2.

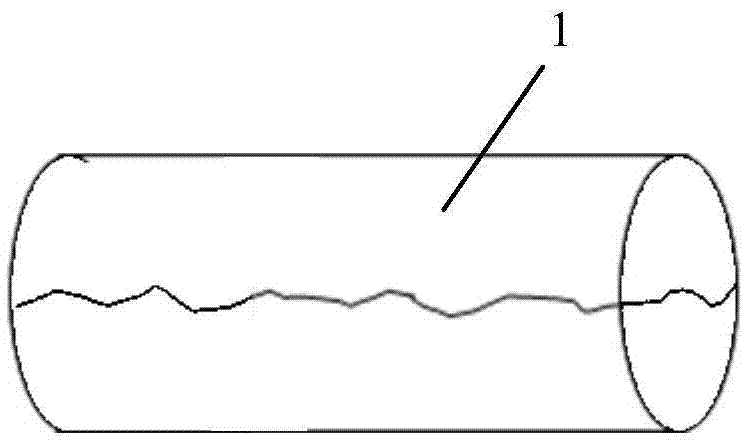

[0045] (2) if figure 2 As shown, a fracture maker is used to create fractures in the core column 1. Preferably, the fractures are located in the middle of the cross section of the core column 1.

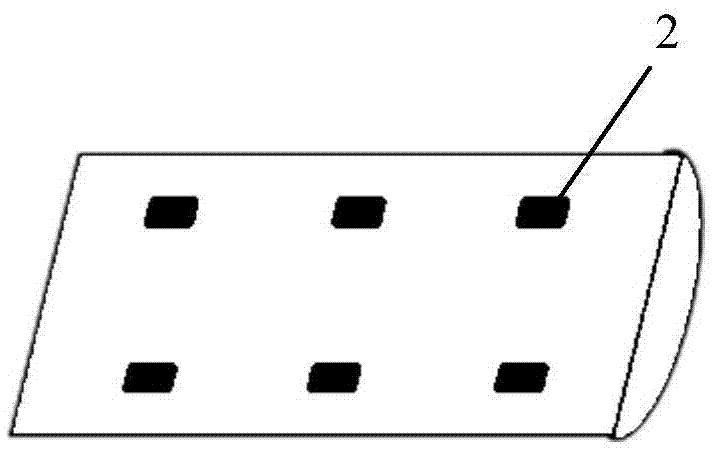

[0046] (3) if image 3 As shown, make a group of rectangular...

no. 2 example

[0054] It should be noted that the rock core prepared in the second embodiment of the present invention can be used in the shale pressure penetration experiment, which can truly reflect the process of pressure transmission in the shale. The concrete steps of rock core preparation method of the present invention are as follows:

[0055] (1) The rock core used in the present invention is real formation shale or outcrop rock. The shape is not required, but the rock surface must be clean.

[0056] (2) Spray a layer of release agent evenly on the inner wall of the mold to facilitate demoulding. Wherein, the diameter of the mold is preferably 35-40 mm, especially 38 mm, but not limited thereto.

[0057] (3) if Figure 7 As shown, a material is injected into the mold to form a wrapping layer 3 for wrapping the core 1'.

[0058] Wherein, the wrapping layer 3 may use epoxy resin and curing agent mixed uniformly in a certain proportion, preferably the epoxy resin and curing agent ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com