Equipment testing method and device applied to thermal power plant

A technology of equipment testing and testing devices, which is applied in the direction of measuring devices, material defect testing, and optical testing for flaws/defects. The effect of saving labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

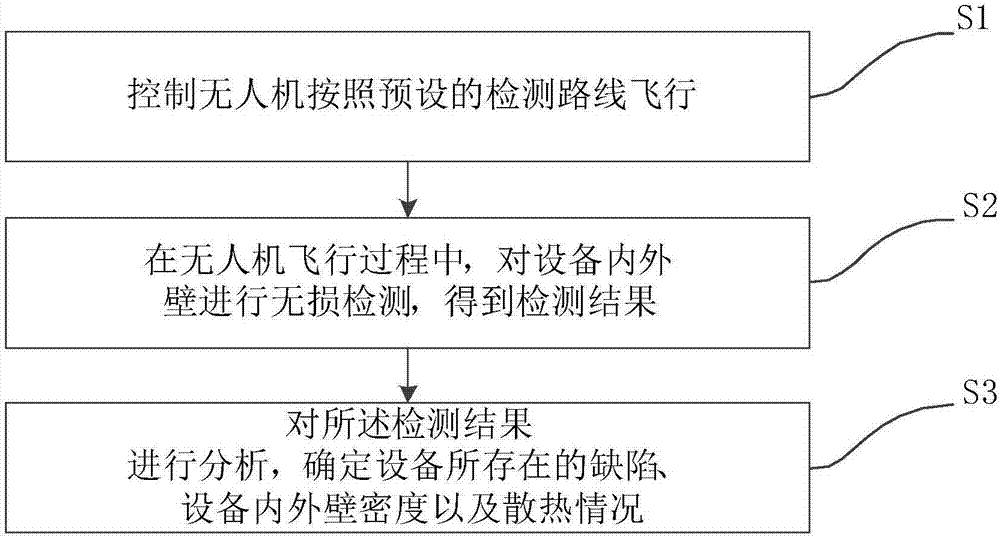

[0036] figure 1 It shows a schematic flowchart of an equipment detection method applied to a thermal power plant provided by Embodiment 1 of the present invention. Such as figure 1 As shown, the device detection method includes:

[0037] Step S1, controlling the UAV 101 to fly according to a preset detection route;

[0038] Step S2, during the flight of the UAV 101, conduct non-destructive testing on the inner and outer walls of the equipment, and obtain the testing results, wherein the equipment includes a boiler, a chimney 200, a desulfurization absorption tower 300 and an air cooling island;

[0039] Step S3, analyzing the detection results to determine the defects existing in the equipment, the density of the inner and outer walls of the equipment, and the heat dissipation.

[0040] The technical scheme of the present embodiment is specifically:

[0041] Step S1, controlling the UAV 101 to fly according to a preset detection route.

[0042] Wherein, the detection rout...

Embodiment 2

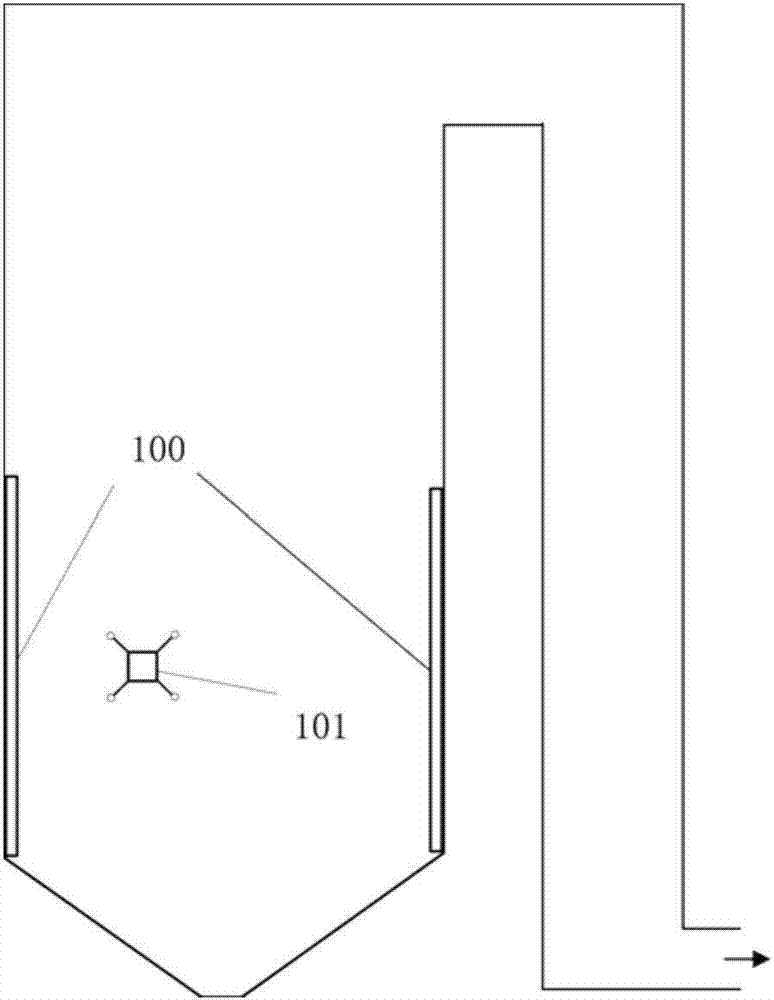

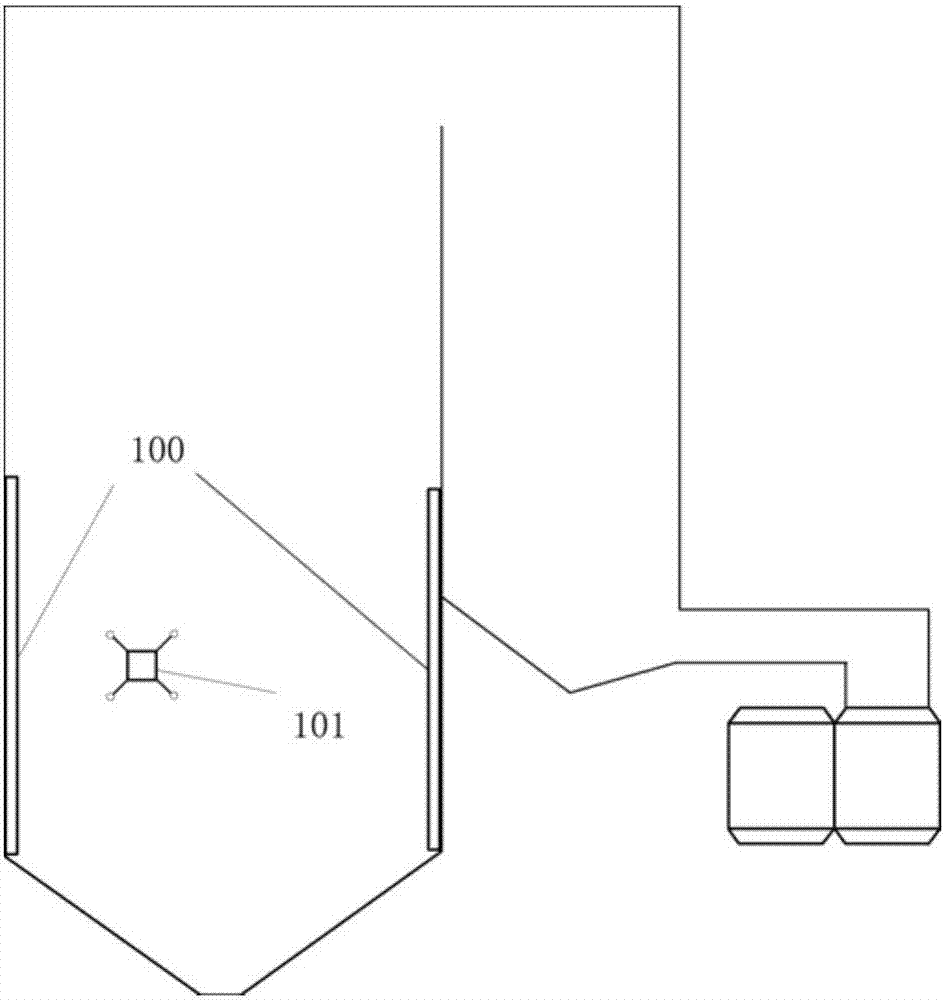

[0056] Corresponding to Embodiment 1 of the present invention, Figure 8 A schematic structural diagram of an equipment detection device applied to a thermal power plant provided by an embodiment of the present invention is shown. Such as Figure 8 As shown, an equipment detection device applied to a thermal power plant includes: an unmanned aerial vehicle 101, a control device 102, a detection device 103, a data analysis device 104, and a lighting device 105; wherein, as Figure 4 As shown, the detection device 103 and the lighting device 105 are both installed on the drone 101 .

[0057] Preferably, the control device 102 is a radio remote controller, which is used to control the UAV 101 to fly according to a preset detection route, control the detection device 103 to perform non-destructive testing on the inner and outer walls of the equipment, and control the lighting device 105 to Lighting during inspection. Wherein, the detection route is preset according to the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com