Variable area ratio ejector based on electronic expansion valve

A technology of electronic expansion valve and injector, which is applied in the direction of injection device, liquid injection device, fluid circulation arrangement, etc., can solve the problems of high process requirements and nozzle movement delay, and achieve the effect of small size, easy installation and miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings (the given examples are only used to explain the present invention, and are not intended to limit the scope of the present invention).

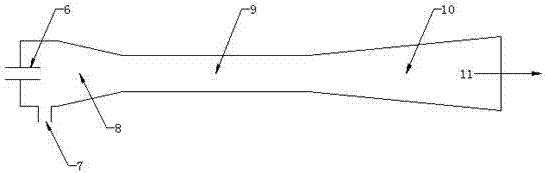

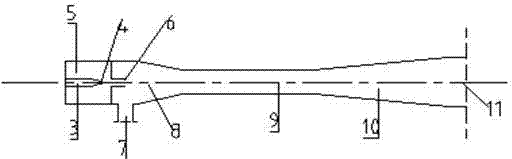

[0020] see figure 1 , A typical injector mainly includes five parts: nozzle 6, secondary flow inlet 7, suction chamber 8, mixing chamber 9 and diffuser section 10. After the high-temperature and high-pressure primary flow fluid at the inlet of the injector passes through the nozzle, the flow rate increases and the pressure decreases, creating a vacuum effect in the suction chamber to suck the secondary flow fluid. The primary flow is fully mixed, and the final mixed fluid passes through the diffuser section, where the velocity decreases and the pressure increases.

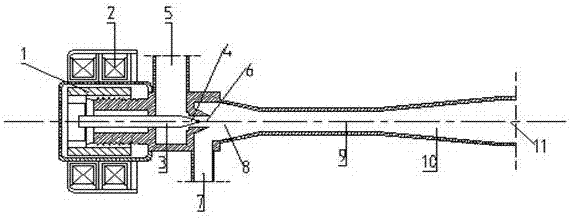

[0021] Please refer to figure 2 , the high-pressure superheated refrigerant vapor (primary flow fluid) in the ejector inlet section 5 passes through the main nozzle 6, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com