Quick clamping fixture suitable for machining of original natural jade with complicated shape

A complex shape and natural technology, applied in the field of quick clamping fixtures and fixtures, can solve the problems of difficult to guarantee clamping reliability, large differences in the position of the surface to be processed, low replacement efficiency, etc. The effect of high clamping efficiency and high clamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

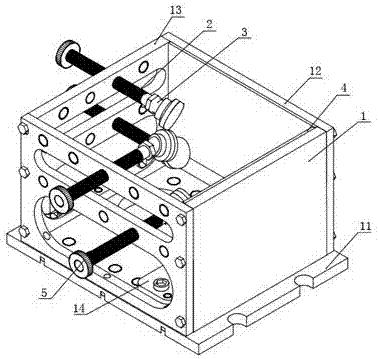

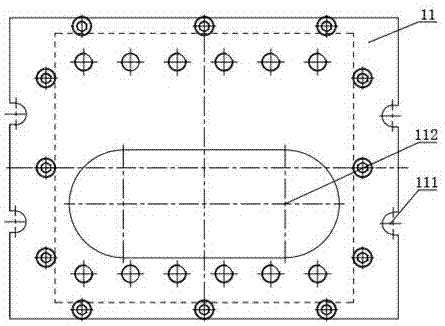

[0016] Embodiment 1: see figure 1 , a fast clamping fixture suitable for processing natural raw jade with complex shapes, including a fixture base 1 and a clamping mechanism 2 . The fixture base 1 is composed of a base plate 11 and four side plates 12 arranged on the base plate and forming a rectangle, forming a stable frame structure. Wherein, at least any two adjacent side plates are provided with a clamping mechanism 2, and the position of the clamping mechanism 2 is adjusted and fixed through the threaded hole 3 located on the side plate; The other side plates not equipped with the clamping mechanism 2 and the bottom plate 11 jointly restrict the movement of the clamped part in X, Y and Z directions.

[0017] One, two or three clamping mechanisms 2 are arranged on the bottom plate 11 .

[0018] The clamping mechanism 2 is composed of a universal support 21 and a screw 22. The universal support 21 includes a spherical mandrel and a spherical sleeve. One end of the spheric...

Embodiment 2

[0020] Embodiment 2: (figure omitted), a quick clamping fixture suitable for processing natural raw jade with complex shapes, including a fixture base and a clamping mechanism. The fixture base is composed of a bottom plate and three side plates arranged on the bottom plate and forming a triangle, forming a stable frame structure. Wherein, any side plate is provided with a clamping mechanism, and the clamping mechanism is composed of a universal support and a screw rod, and the screw rod passes through the threaded hole and is perpendicular to the side plate, and the position is adjusted by the and fixed; the clamping head of the clamping mechanism 2 together with the other side plates and the bottom plate 11 not equipped with the clamping mechanism limit the movement of the clamped piece in the X, Y and Z directions.

Embodiment 3

[0021] Embodiment 3: (figures omitted), a quick clamping fixture suitable for complex-shaped natural raw jade processing, including a fixture body and a telescopic mechanism, the fixture is a polygonal hollow structure, and the upper part is an open structure to form The storage opening for placing the workpiece to be clamped is provided with a telescopic mechanism on at least two sides of the fixture body that are perpendicular to the plane where the storage opening is located and adjacent to each other. The working direction of the telescopic mechanism is perpendicular to The surface where it is located points to the inside of the fixture body. A universal support is connected to the inner end of the telescopic mechanism. The telescopic mechanism pushes the universal support to move along the working direction of the telescopic mechanism so that the universal support is the same as the universal support The opposite surface and the surface far away from the storage opening jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com