Gas water heater control system conducting adjustment according to gas secondary pressure

A gas water heater and control system technology, applied in fluid heaters, lighting and heating equipment, etc., can solve problems such as inability to effectively close gas passages, hidden safety hazards, and increased risk of gas leakage, so as to improve water comfort and facilitate control , The effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate those skilled in the art to better understand the essence of the present invention, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

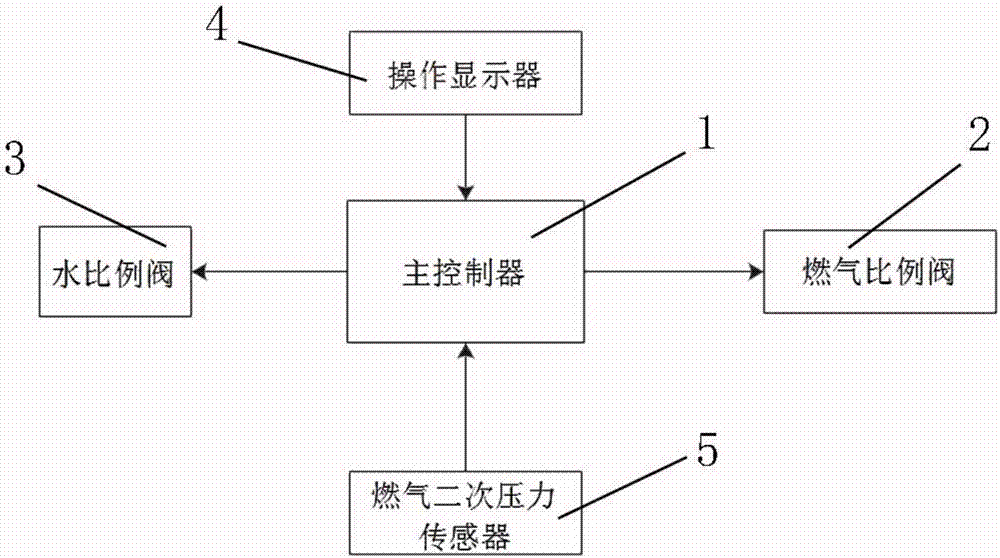

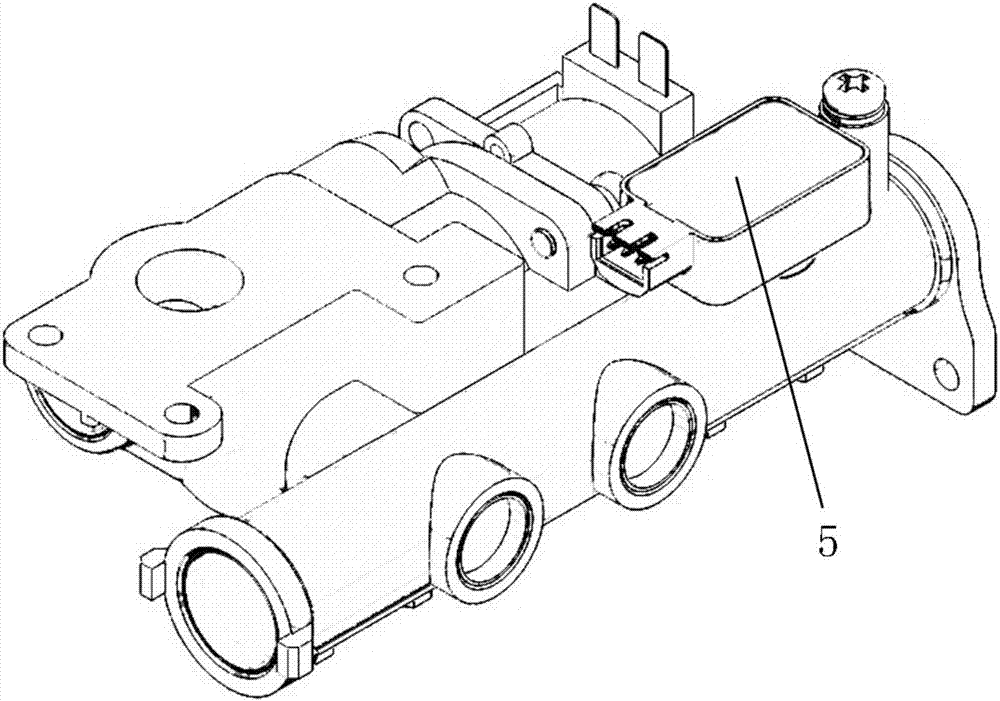

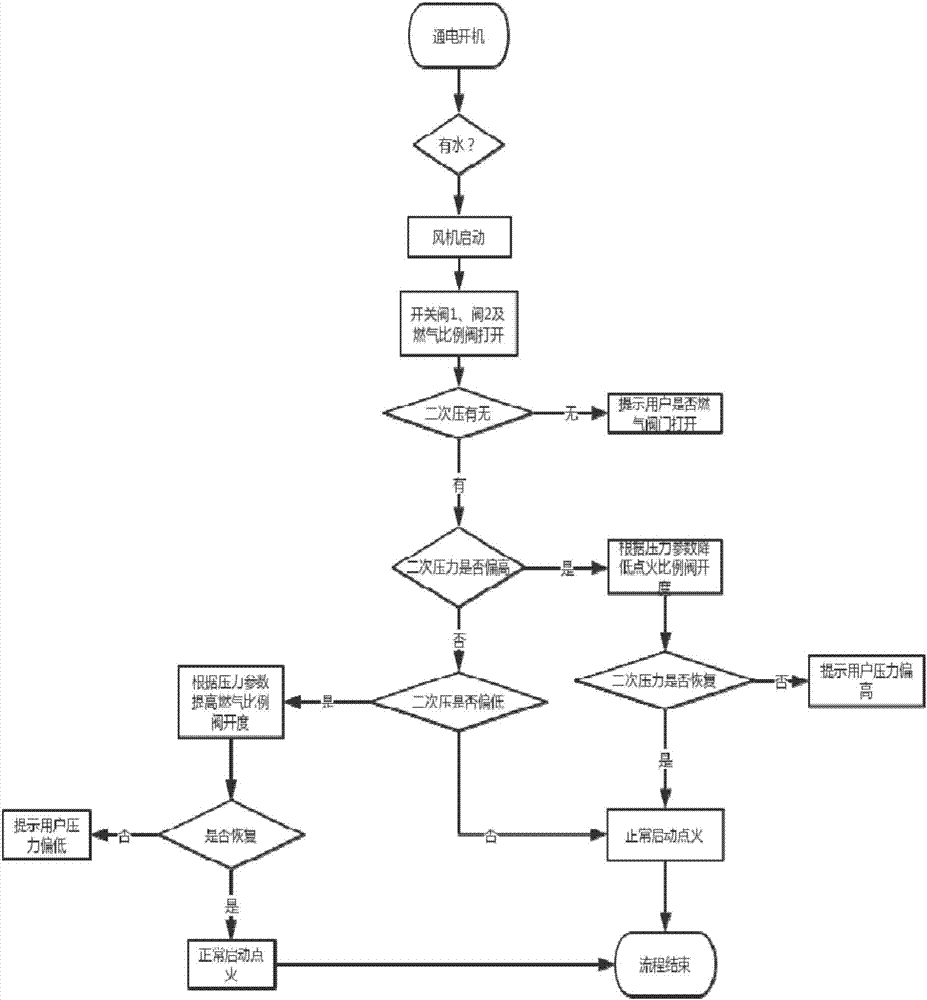

[0019] Such as figure 1 , figure 2 As shown, a gas water heater control system includes: a main controller 1, a gas proportional valve 2, a water proportional valve 3, an operation display 4, and a secondary pressure sensor 5 connected to the main controller 1. The gas secondary pressure The sensor 5 is installed on the gas square pipe of the whole machine and is located after the function of the two-way switch cut-off valve to directly test the gas output secondary pressure. The installation structure of the secondary pressure sensor 5 is that the wall of the secondary gas pipeline extends to the gas In the secondary pipeline, the gas secondary pressure values corresponding to different load states of the gas water heater are stored in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com