An extruding garlic seed splitting device

An extruded, split-valve technology, applied in the fields of seed and rhizome processing, agriculture, food science, etc., can solve problems such as low work efficiency, reduce the rate of double and multi-valve, reduce the rate of skin breakage, and avoid prolonged The effect of repeated squeezing and rubbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

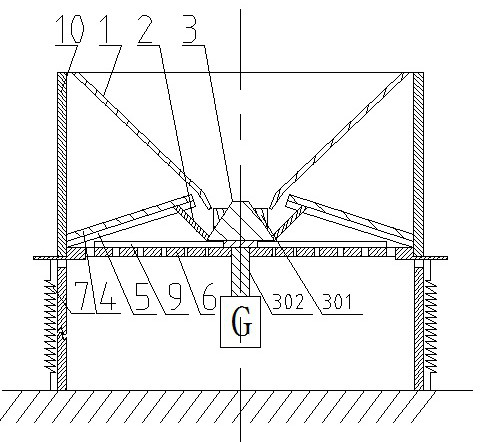

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

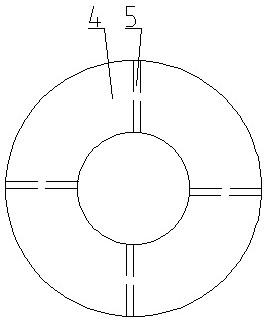

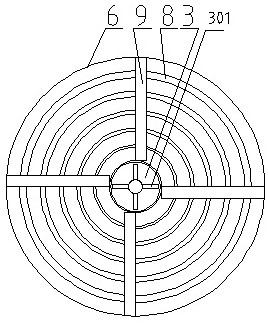

[0020] Such as Figure 1~3 , the described a kind of extrusion type garlic splitting device comprises a cylindrical frame 10, a feed hopper 1 of the self-weight feeding type arranged in the frame 10, an upper part arranged below the feed hopper 1 The extruding plate 4 and the lower extruding plate 6 horizontally arranged below the upper extruding plate 4, wherein the angle between the upper extruding plate 4 and the lower extruding plate 6 is θ to form an extruding chamber, θ is an acute angle, It is characterized in that: directly below the feed hopper 1 and at the center of the lower extrusion plate 6, a garlic guide cone 3 that can dial the garlic into the space between the upper extrusion plate 4 and the lower extrusion plate 6 is provided through rotation, and the garlic guide Garlic cone platform 3 is connected with upper extruding plate 4 by connecting piece. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com