Dry beneficiation process for extracting iron ore concentrates from extremely lean sand iron ore

A technology for iron concentrate and iron ore, which is applied in the field of dry beneficiation technology for extracting iron concentrate, can solve the problems of low ore yield, complicated process and high investment, and achieves low development cost, reduced processing capacity and fine particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take the beneficiation of an iron sand ore containing 6.88% magnetic iron in a sandy loose accumulation in China as an example.

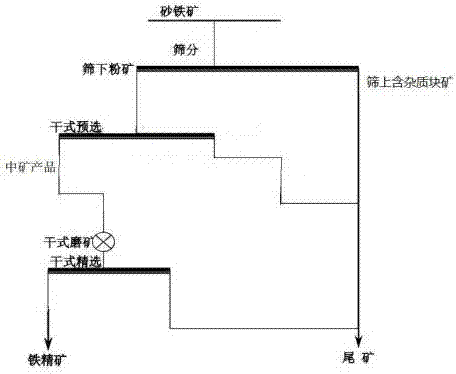

[0024] use as figure 1 The shown dry beneficiation process for extracting iron concentrate from extremely lean sand iron ore has the following process steps:

[0025] (1) Screening and removing impurities of iron placer ore: feed iron placer ore into a vibrating screen with a sieve hole size of 3mm to obtain lump ore containing impurities on the sieve and fine ore under the sieve;

[0026] (2) Dry pre-selection: feed the fine ore obtained in step (1) into a dry-type magnetic separator with a magnetic field strength of 0.2t and a drum line speed of 0.6m / s for magnetic separation to obtain medium ore products and weak magnetic or non-magnetic For tailings products, the ore grade is increased to 16.12%, the yield is 18.71%, the iron recovery rate is 43.86%, and 81.29% of the weakly magnetic or non-magnetic tailing waste sand is discarded, and t...

Embodiment 2

[0030] Take the beneficiation of an iron sand ore containing 3% magnetic iron in a sandy loose accumulation in China as an example.

[0031] use as figure 1 The shown dry beneficiation process for extracting iron concentrate from extremely lean sand iron ore has the following process steps:

[0032] (1) Screening and removing impurities of iron placer ore: feed iron placer ore into a vibrating screen with a screen hole size of 8mm to obtain lump ore containing impurities on the screen and fine ore under the screen;

[0033] (2) Dry pre-selection: Feed the fine ore obtained in step (1) into a dry magnetic separator with a magnetic field strength of 0.5t and a drum line speed of 1.2m / s for magnetic separation, and then feed it into a magnetic field with a strength of 0.4t. The dry magnetic separator with a speed of 1.8m / s performs secondary magnetic separation to obtain medium ore products and weak magnetic or non-magnetic tailings products, and the ore grade is increased to 23...

Embodiment 3

[0037] Take the beneficiation of a sandy iron sand ore containing 10% magnetic iron as an example.

[0038] use as figure 1 The shown dry beneficiation process for extracting iron concentrate from extremely lean sand iron ore has the following process steps:

[0039] (1) Iron placer ore screening and impurity removal: Feed placerite ore into a vibrating screen with a sieve hole size of 12mm to obtain lump ore with impurities on the sieve and fine ore under the sieve, and the yield on the sieve is 11.21%;

[0040] (2) Dry pre-selection: Feed the fine ore obtained in step (1) into a dry magnetic separator with a magnetic field strength of 0.3t and a drum line speed of 1.8m / s for magnetic separation. Magnetic gangue, ore iron grade increased to 17%;

[0041] (3) Dry grinding: dry-type closed-circuit grinding is performed on the medium ore product obtained in step (2) to obtain a grinding product with a particle size of less than 200 mesh and a particle fraction content of 30%; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com