Grinding method of rust on outer ring of automobile wheel bearing

A technology for bearing outer ring and automobile wheel hub, applied in the field of grinding tools, can solve problems such as poor appearance, labor-intensive, difficult assembly, etc., to ensure the quality of grinding and rust removal, improve grinding efficiency, and avoid the effect of bearing scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

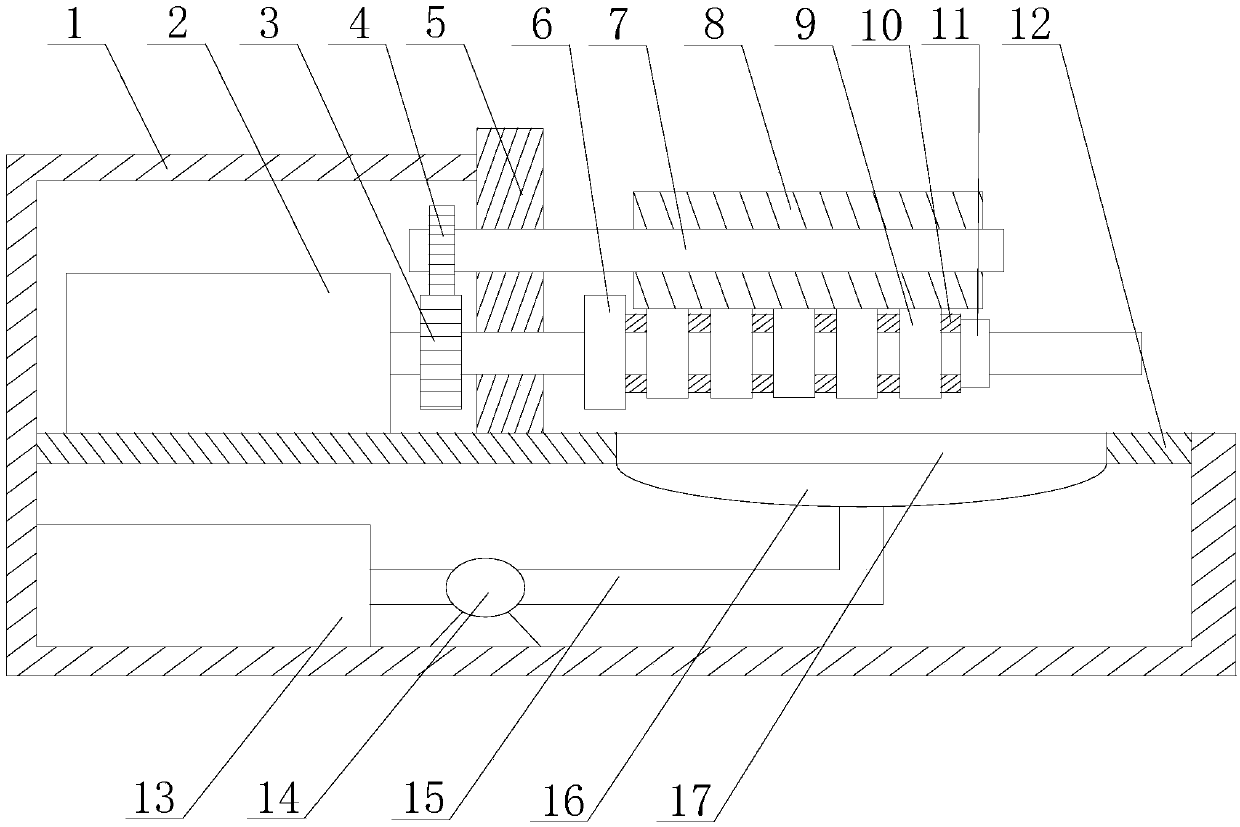

[0021] Such as figure 1 As shown, this embodiment includes the following steps: Firstly, a plurality of bearings 9 and washers 10 are alternately sleeved on the extension section of the output end of the motor 2, and then the nuts 11 are tightened so that the plurality of bearings 9 and washers 10 are tightened. Fix between the screw nut 11 and the limit block 6, start the motor 2, and at the same time when the output end of the motor 2 starts to rotate, the driving gear 3 drives the driven gear 4, forcing the rotating shaft 7 to drive the brush 8 to start rotating, and the brush 8 starts to rotate. The rust on the circumferential wall of the bearing 9 is polished and cleaned; after the rust is thrown out, it falls from the rectangular hole 17, and the fan 14 is started to generate a traction force on the rust in the rectangular hole 17 at the bottom of the support plate 12 to drive the rust scattered on the cover body. The iron rust in 16 quickly moves into the storage box 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com