Stable and reliable bearing polishing machine

A polishing machine and bearing technology, applied in the field of grinding tools, can solve problems such as poor appearance, difficult assembly, poor reliability, etc., and achieve the effect of ensuring the quality of grinding and derusting, avoiding scrapping of bearings, and consistent grinding progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

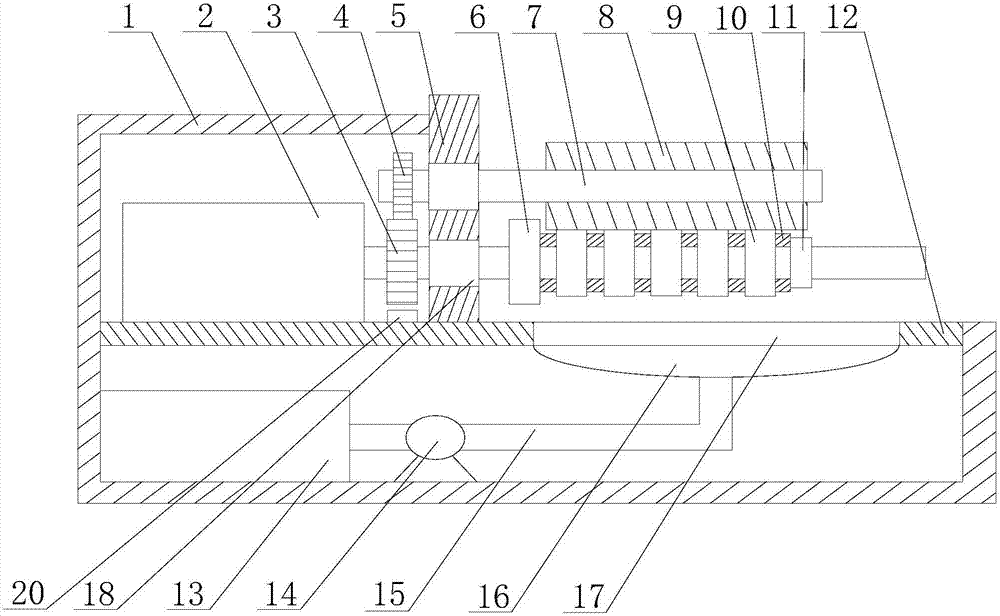

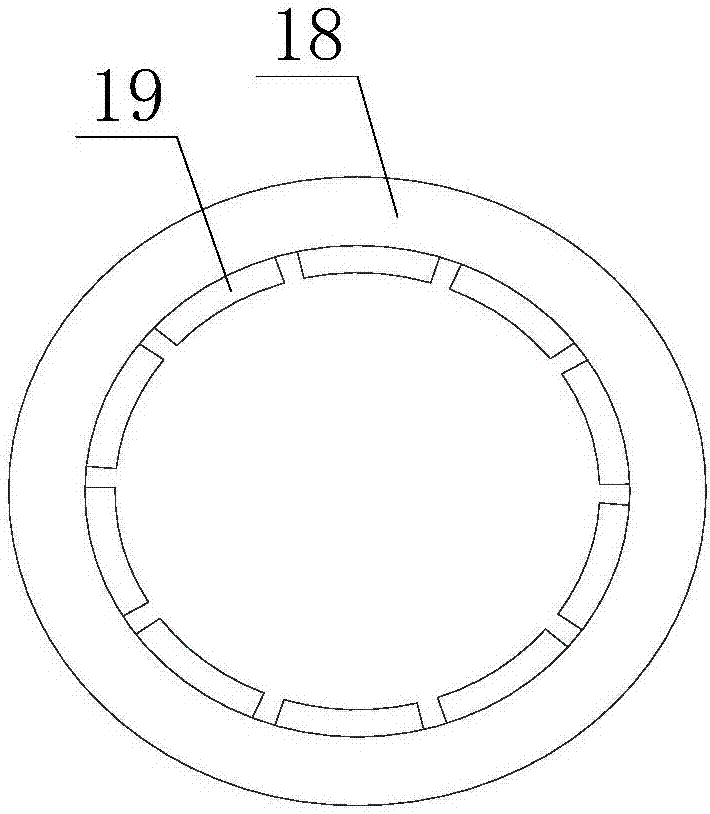

[0022] Such as Figure 1~2 As shown, this embodiment includes a U-shaped frame 1 and a support plate 12 fixed in the frame 1. A motor 2 and a column 5 are respectively installed on the support plate 12, and the output end of the motor 2 moves through the column. 5 extends outward horizontally after the lower section, and the rotating shaft 7 moves through the upper section of the column 5 and is parallel to the output end of the motor 2. The output end of the motor 2 is provided with a driving gear 3 and a limit block 6 respectively located on both sides of the column 5 , there is an external thread on the extension section of the output end of the motor 2, the screw nut 11 cooperates with the external thread, and a plurality of washers 10 are set between the limit block 6 and the screw nut 11, and the bearings 9 are alternately arranged on the two washers 10, the outer diameter of the washer 10 is greater than the inner diameter of the outer ring of the bearing 9, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com