Firing device capable of removing inner carbon ash and eliminating noise

A technology of trigger and noise reduction, applied in nailing tools, manufacturing tools, etc., can solve problems such as loud noise, firing duds, blocking, etc., to eliminate noise, improve work efficiency, and reduce damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

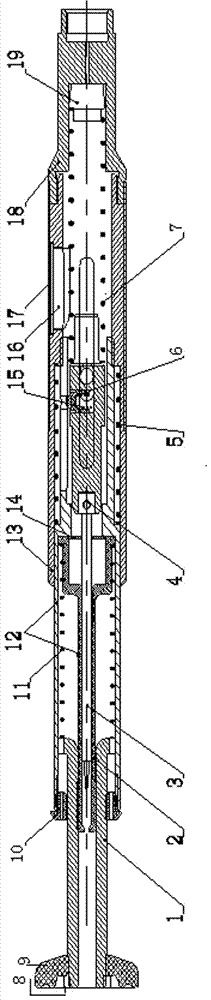

[0012] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0013] Such as figure 1 As shown, a firing device with inner carbon dust removal and silencer includes a kinetic energy bore tube 1, a firing pin casing 2, a firing pin 3, a positive front end cover 10, an outer casing 12, a firing pin shaft lock pin 6, and a firing pin cover The tube 2 is arranged in the kinetic energy bore tube 1, and four single surfaces are milled on the outer diameter of the step of the kinetic energy bore tube 1, and the two sides are symmetrically and evenly distributed. The firing pin 3 is set in the firing pin sleeve 2, and the firing pin sleeve 2 is provided with an energy release hole 3~9 cm away from the end face of the small step, and the firing pin sleeve 2 is provided with a uniform hole 3~9 cm away from the end face of the large step. The soot exhaust hole o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com