Food high pressure pump pulsation reduction device

A high-pressure pump and food technology, applied in the direction of pump components, pulse balance, machine/engine, etc., can solve problems such as colony reproduction, hidden dangers of production system safety, and unsatisfactory effect of buffer to eliminate pulsation, so as to absorb fluctuations in flow and pressure , stable flow and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

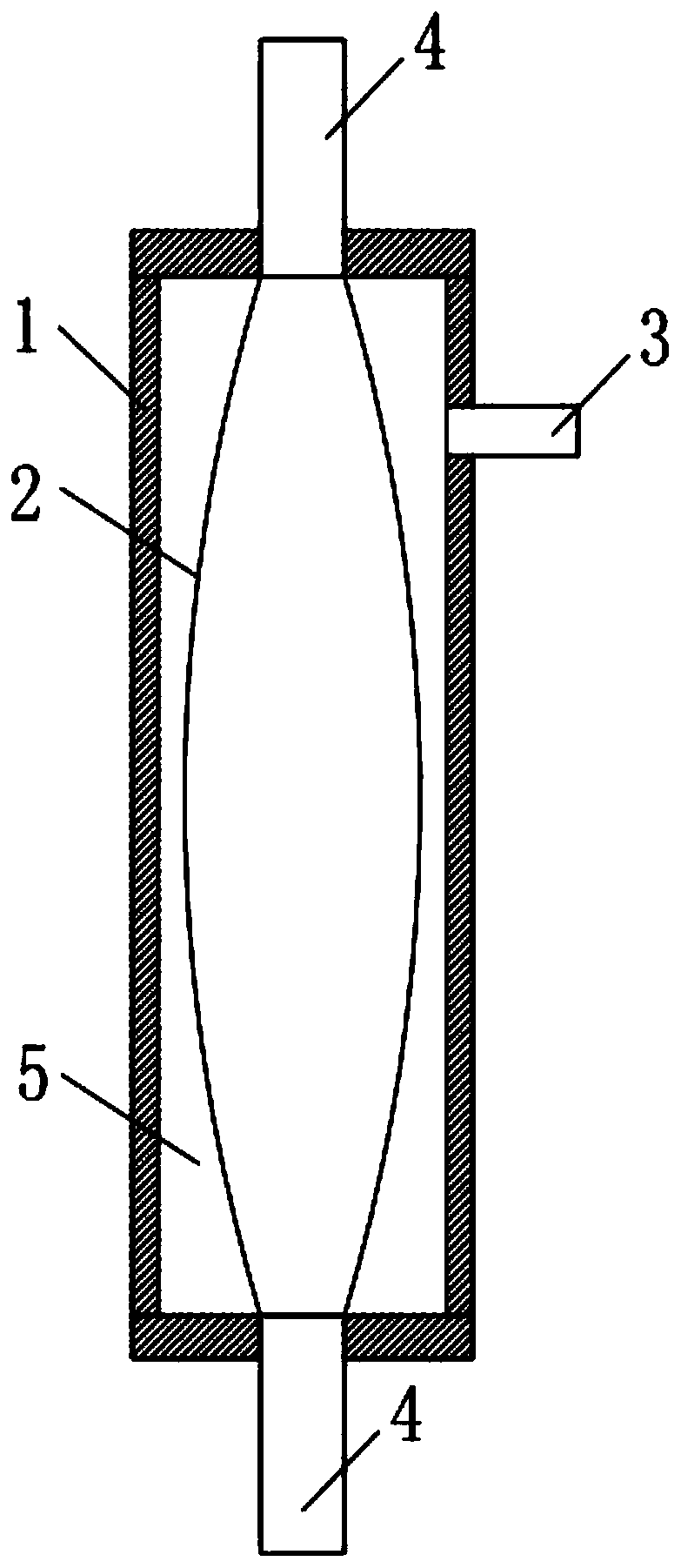

[0032] Such as figure 1 As shown, in this embodiment, the food high-pressure pump pulsation reduction device includes a housing 1 with a housing space, an air bag 2, an inflator 3 and a connecting device 4. The housing 1 is a cylindrical structure, and both ends are provided with There are connecting devices 4, respectively connected to the inlet and outlet of the material of the production system, the airbag 2 is arranged in the housing 1, and its two ends communicate with the connecting devices 4 at the two ends of the housing 1 respectively A closed air chamber 5 is formed between the inner wall of the housing 1 and the air bag 2 , the inflator 3 is arranged on the side wall of the housing 1 , and the air chamber 5 communicates with the inflator 3 .

[0033] In this embodiment, in order to ensure the pressure bearing capacity and service life of the high-pressure pulsation buffer, the aspect ratio of the housing 1 is greater than 5, and the ratio of the outer diameter to th...

Embodiment 2

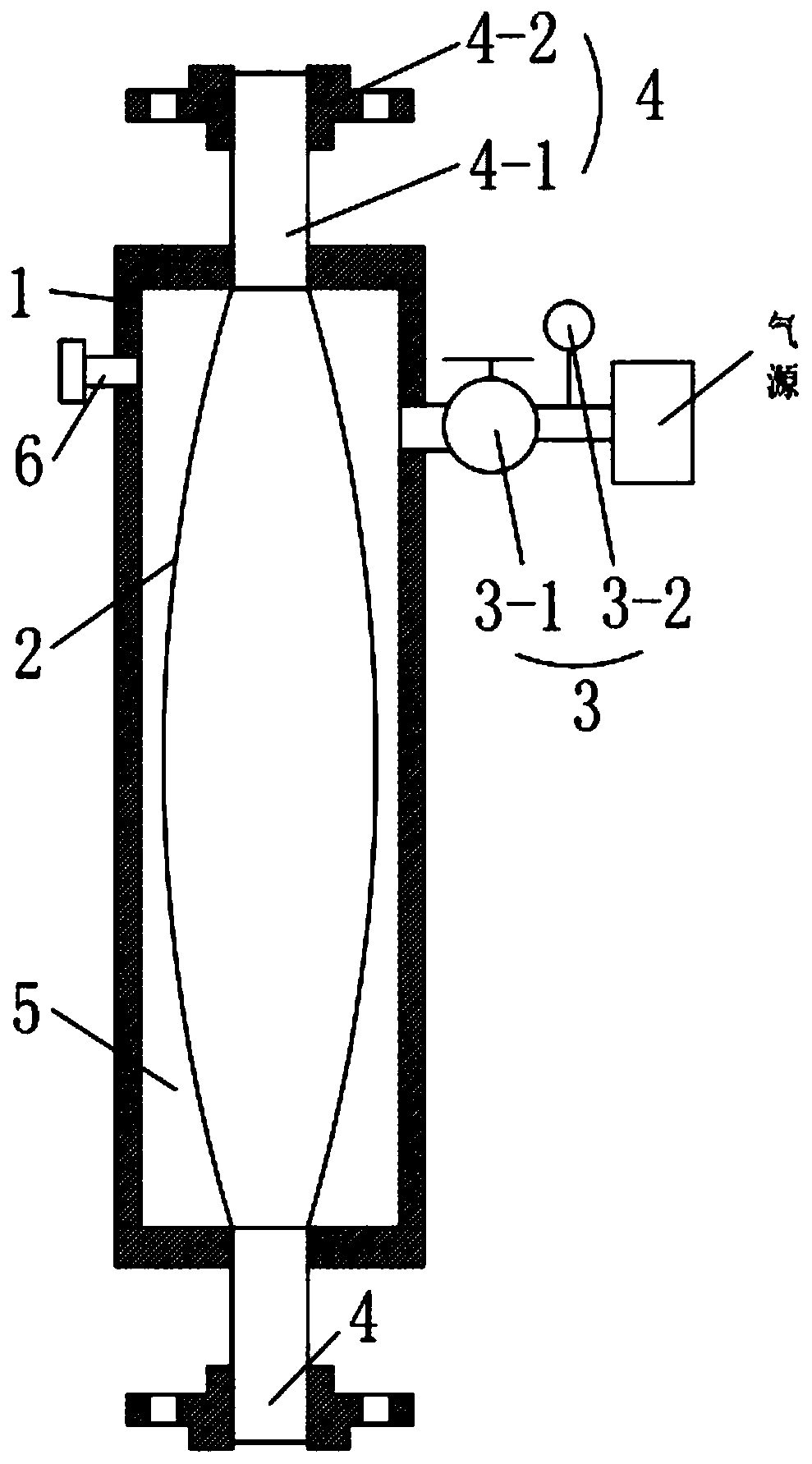

[0037] Such as figure 2 As shown, in this embodiment, the inflation device 3 includes an inflation valve 3-1 and a pressure gauge 3-2, and the inflation valve 3-1 is fixedly arranged on the side wall of the housing 1 and connected to the 5, the other end of the inflation valve 3-1 communicates with the gas source through the inflation tube, and the pressure gauge 3-2 is arranged on the inflation tube.

[0038]In this embodiment, the connection device 4 includes an infusion tube 4-1 and a flange 4-2, one end of the infusion tube 4-1 is fixedly connected to the end of the housing 1 and connected to the airbag 2 communicates internally, and its other end is fixedly connected to the mounting hole provided at the center of the flange 4-2 and passing through the flange 4-2.

[0039] In this embodiment, the housing 1 is further provided with a safety valve 6 connected to the air chamber 5 .

[0040] In this embodiment, the connecting device 4 is connected in a way of flange butt j...

Embodiment 3

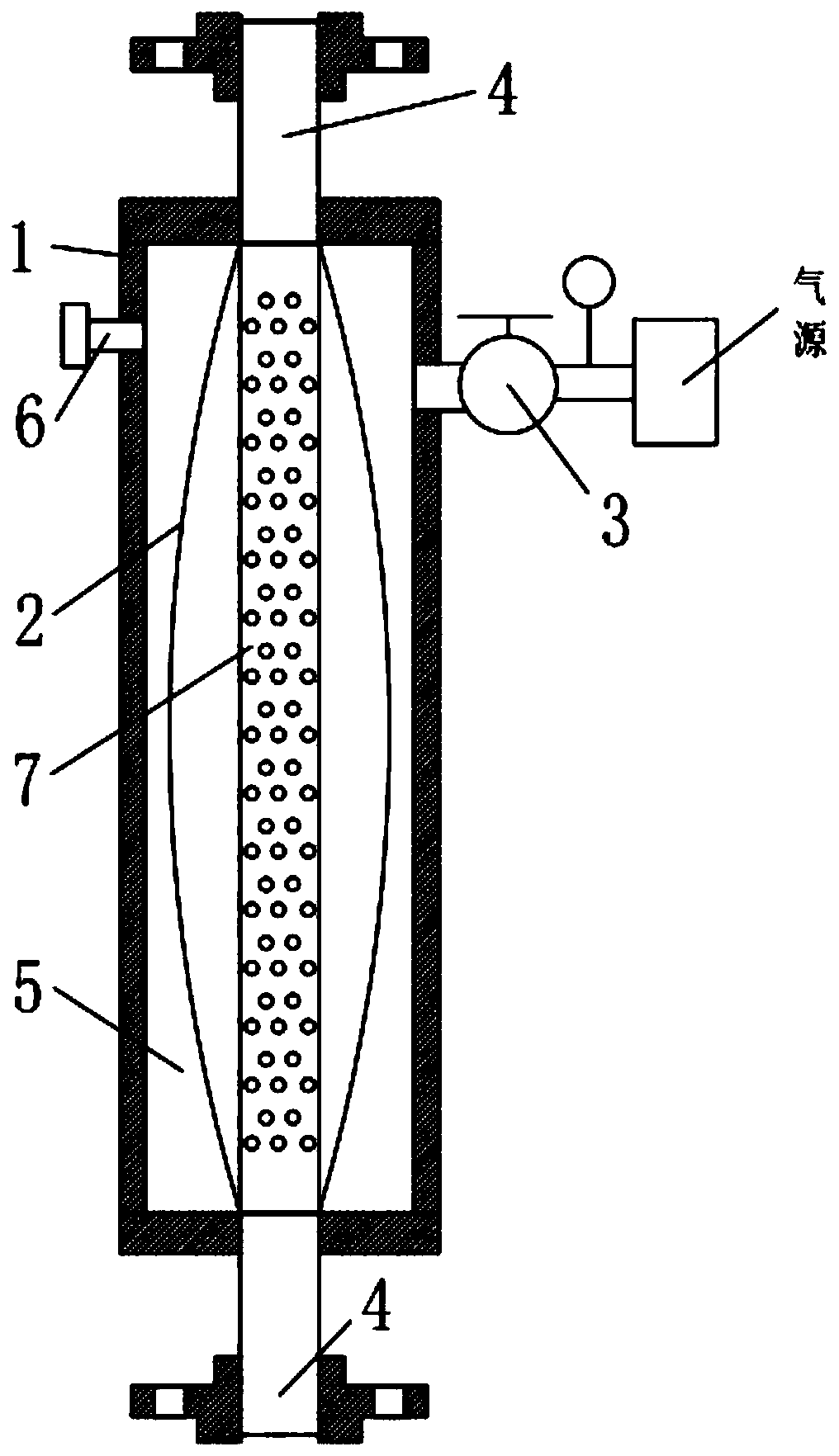

[0045] Such as Figure 3 to Figure 4 As shown, in this embodiment, the airbag 2 is sleeved with a flow stabilizer 7, and the flow stabilizer 7 includes a cylinder body 7-1 with a straight structure, and the two ends of the cylinder body 7-1 are respectively connected to the The infusion tube 4-1 at both ends of the housing 1 is fixedly connected, and the side wall of the cylinder body 7-1 is evenly distributed with a number of through holes penetrating the cylinder wall, and the inner middle position of the cylinder body 7-1 is transversely perpendicular to the cylinder wall. The wall is fixedly provided with a stabilizing plate 7-2, and several through holes are uniformly arranged on the stabilizing plate 7-2.

[0046] In this embodiment, the flow stabilizer 7 is set so that when the airbag 2 expands and contracts, the liquid material needs to pass through the through hole on the cylinder wall of the cylinder 7-1, so as to achieve the effect of slowing down the flow rate, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com