Composite sealing packaging box

A composite material and packaging box technology, used in packaging, transportation and packaging, rigid containers, etc., can solve the problems of poor structural strength of composite material packaging boxes, damage to the box body, etc. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

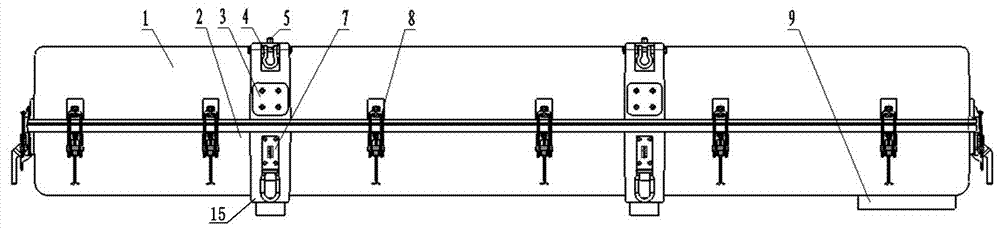

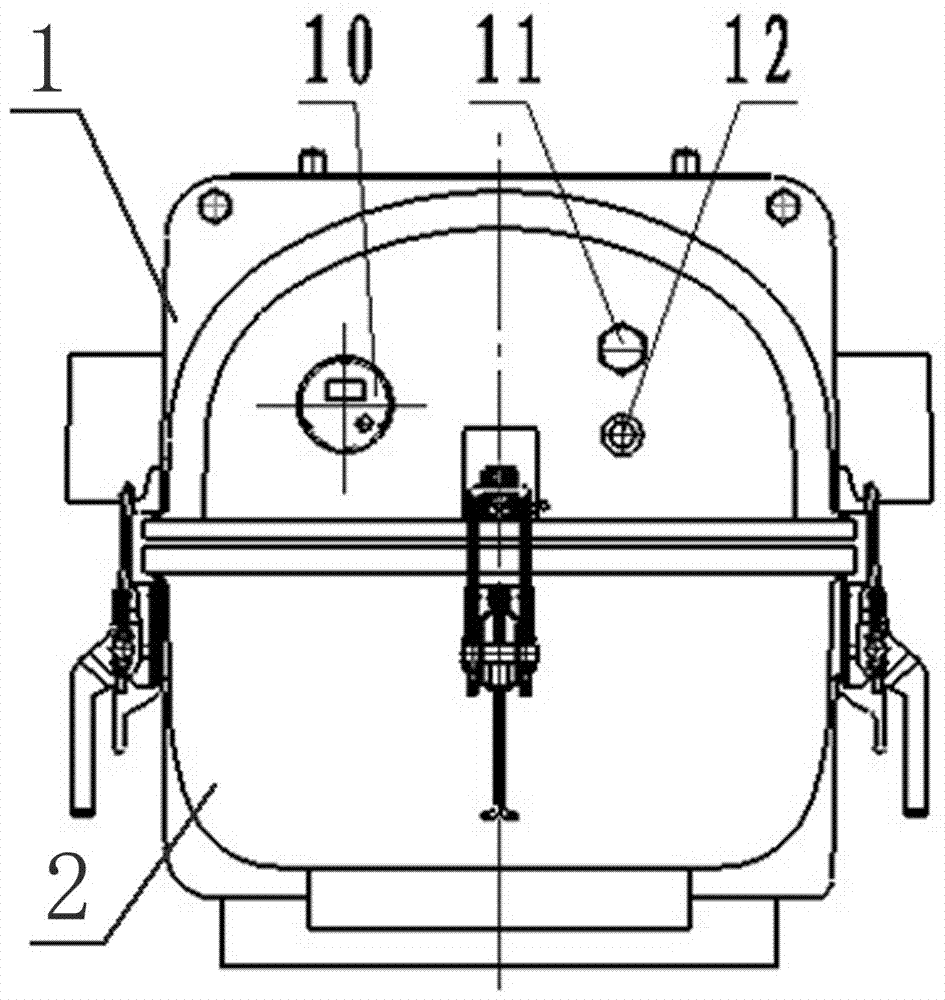

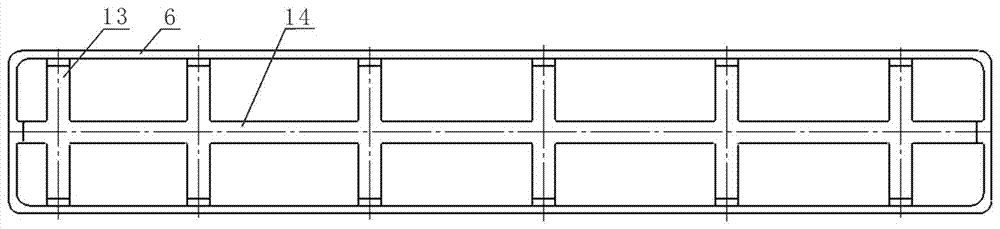

[0017] Composite material sealed packaging box, including a box cover 1 with a semicircular cross-section and a box body 2 with a rectangular cross-section. The box cover 1 and the box body 2 are fixed to each other by a number of evenly distributed buckles. Pressure device 10, pressure equalizing valve 11 and inflation valve 12, the inner wall of box cover 1 is provided with circumferential reinforcement rib 13 and longitudinal reinforcement rib 14, the bottom edge of box cover 1 is provided with box mouth frame 6, circumferential reinforcement rib 13 and longitudinal reinforcement The ribs 14 all extend to the frame of the box mouth 6, the inner wall of the box body 2 is provided with a circumferential reinforcement rib 13 and a longitudinal reinforcement rib 14, the top edge of the box body 2 is provided with a box mouth frame 6, and the box mouth frame 6 of the box body 2 is provided with a box The body seal 24, the circumferential reinforcing rib 13 and the longitudinal re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com