A wind turbine mechanical electromagnetic composite main drive system

A main transmission system and electromagnetic composite technology, which is applied in the direction of wind turbines, mechanical power transmission, mechanical equipment, etc., can solve the problem of heavy permanent magnet direct drive wind turbine generators and permanent magnet direct drive wind turbine generators. Problems such as large volume and affecting the stable operation and profitability of wind farms can achieve the effect of reducing design cost, reducing design difficulty, and small radial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

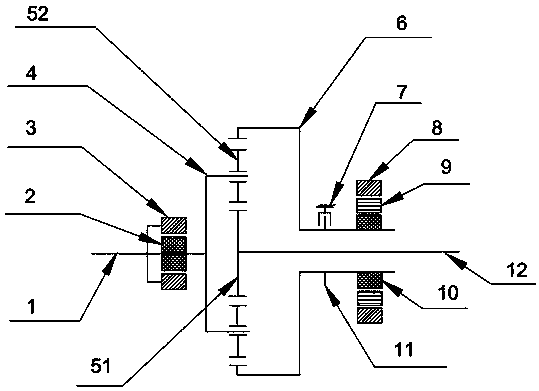

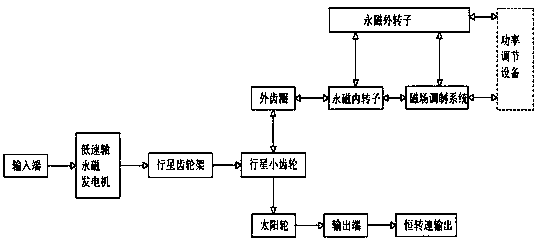

[0017] Such as figure 1 As shown, a wind turbine mechanical electromagnetic composite main transmission system of the present invention belongs to the field of wind power generation, and particularly relates to a large-scale grid-connected wind turbine, which utilizes a permanent magnet generator, a planetary gear train, and a magnetic field modulation magnetic gear motor to realize wind power. The main transmission system of the wind turbine can be driven by an adjustable speed ratio to achieve the purpose of improving the reliability of the wind turbine, making the wind turbine more friendly to the grid, and reducing the load of the speed-up gear, providing a new technical route for the design and development of the high-power wind turbine main transmission system ;

[0018] It specifically includes input transmission shaft 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com