Steam boiler

A technology for steam boilers and drums, applied in steam boilers, water-tube steam boilers, boiler water pipes, etc., can solve the problems of inability to stabilize the flow, low heat absorption efficiency of the riser, and difficulty in entering and passing fluids, reducing the Noise and vibration, improve the effect of steady flow, improve the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0047] In this article, if there is no special explanation, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

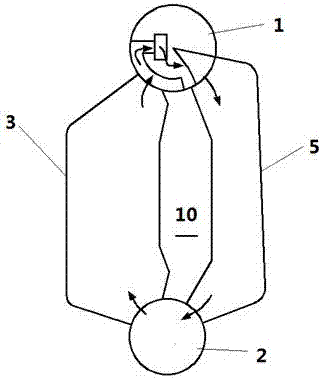

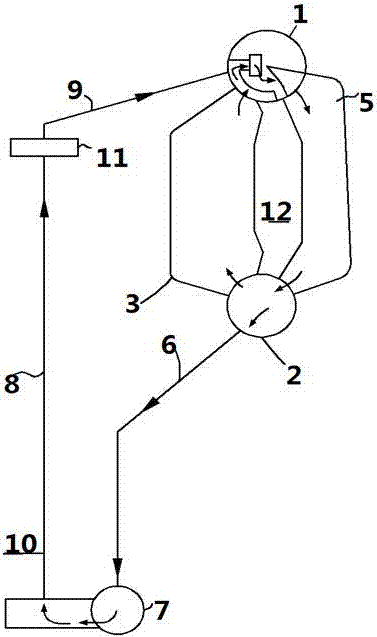

[0048] Such as figure 1 The aforementioned steam boiler includes an upper drum 1 and a lower drum 2 , and the ascending tube 3 and the downcomer 5 connect the upper drum 1 and the lower drum 2 . Water enters the downcomer 5 from the upper drum 1 . The water flows down in the downcomer and is collected in the lower drum 2. The riser 3 of the boiler is heated by the combustion of fuel in the combustion chamber 10 of the furnace. The heat absorbed by the riser 3 causes the liquid inside the tube to boil, thereby creating a two-phase mixture of water and steam. The two-phase mixture in the riser 3 reaches the upper drum 1 . The supercooled water released from the water supply pipe (not shown) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com