A device for dynamically measuring the combustion and sintering characteristics of fine particle samples and a method for measuring characteristic parameters using the device

A technology of dynamic measurement and fine particles, applied in the direction of material thermal development, etc., can solve the problems of inaccurate measurement of combustion characteristic parameters, and achieve more accurate diameter expansion/shrinkage and circularity, satisfying universality and convenience The effect of reliable installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

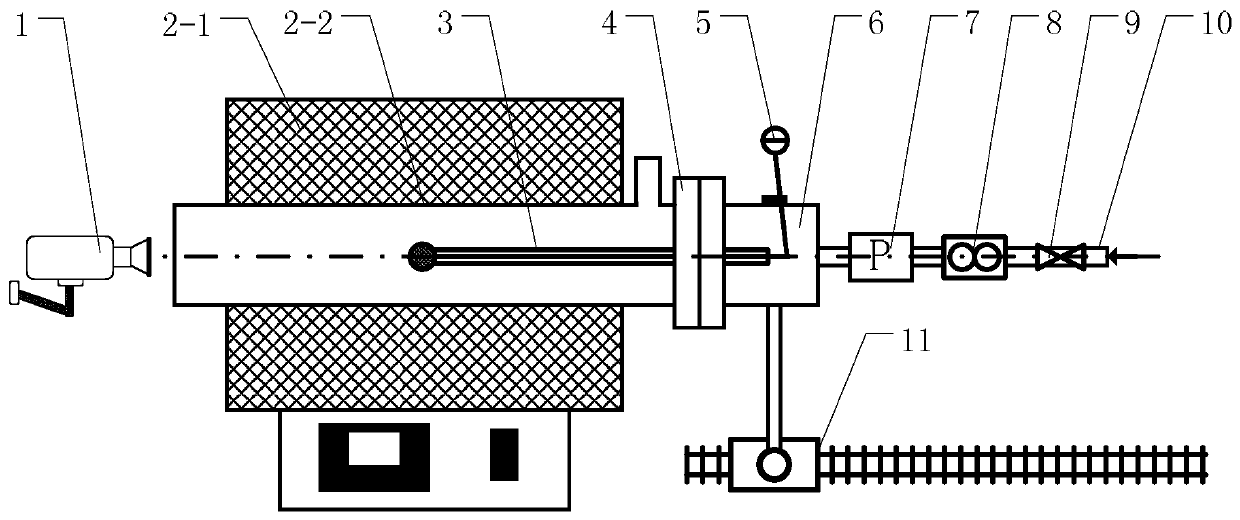

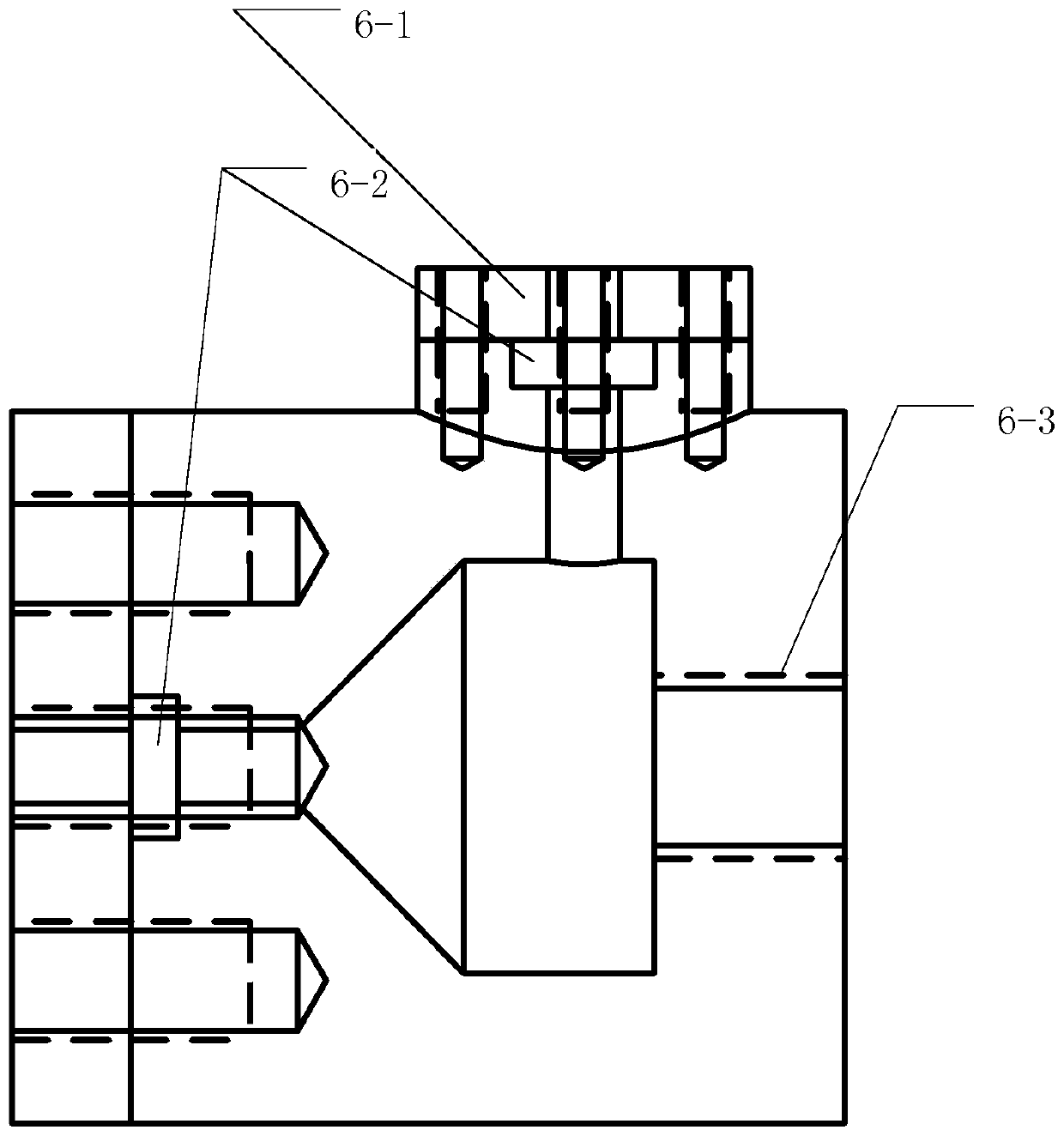

[0042] Specific implementation mode one: refer to figure 1 Specifically explain this embodiment, a device for dynamically measuring the combustion and sintering characteristics of a fine particle sample described in this embodiment, including: a video acquisition device 1, a heating furnace, a temperature acquisition device 5, a sealing member 6, and a pressure acquisition device 7 and flow meter 8;

[0043] The heating furnace 2-1 comprises a heating insulation layer and a quartz tube 2-2, and the heating insulation layer is wrapped on the outside of the quartz tube 2-2,

[0044] The video acquisition device 1 is located at the head end of the quartz tube 2-2, and the end of the quartz tube 2-2 is sealed and connected with the sealing member 6, and the sample 3 to be tested is located at the center of the quartz tube 2-2,

[0045] The gas outlet end of the gas circuit 10 communicates with the inside of the test sample 3 through the sealing member 6, and the gas circuit 10 is...

specific Embodiment approach 2

[0055] Embodiment 2: This embodiment is a further description of the device for dynamically measuring the combustion and sintering characteristics of fine particle samples described in Embodiment 1. In this embodiment, the heating furnace is a programmable horizontal heating furnace.

specific Embodiment approach 3

[0056] Specific embodiment three: This embodiment is a further description of a device for dynamically measuring the combustion and sintering characteristics of fine particle samples described in specific embodiment one. In this embodiment, the head end of the quartz tube 2-2 is made of a transparent Window seal.

[0057] In this embodiment, the first end of the quartz tube 2-2 is sealed with a transparent window. At this time, the quartz tube 2-2 is in a fully sealed state, and the internal gas pressure of the quartz tube 2-2 can be adjusted according to the measurement needs. The dimensional change process of the sample 3 to be tested can be collected through the transparent window.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com