Simulation test device of electric pile cathode of air supply system of fuel cell

An air supply and fuel cell technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problem of not providing equipment, not being able to quickly design an air supply auxiliary system, and the parameters of key components cannot be well matched, etc. problems, to achieve the effect of improving development efficiency and speeding up the matching testing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

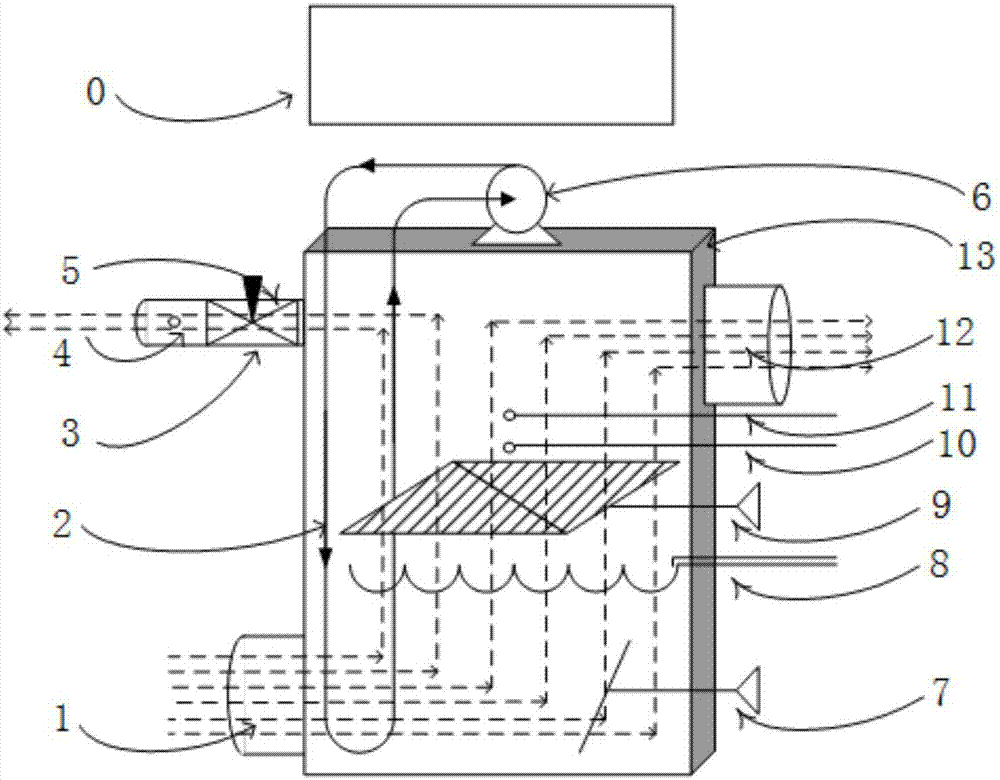

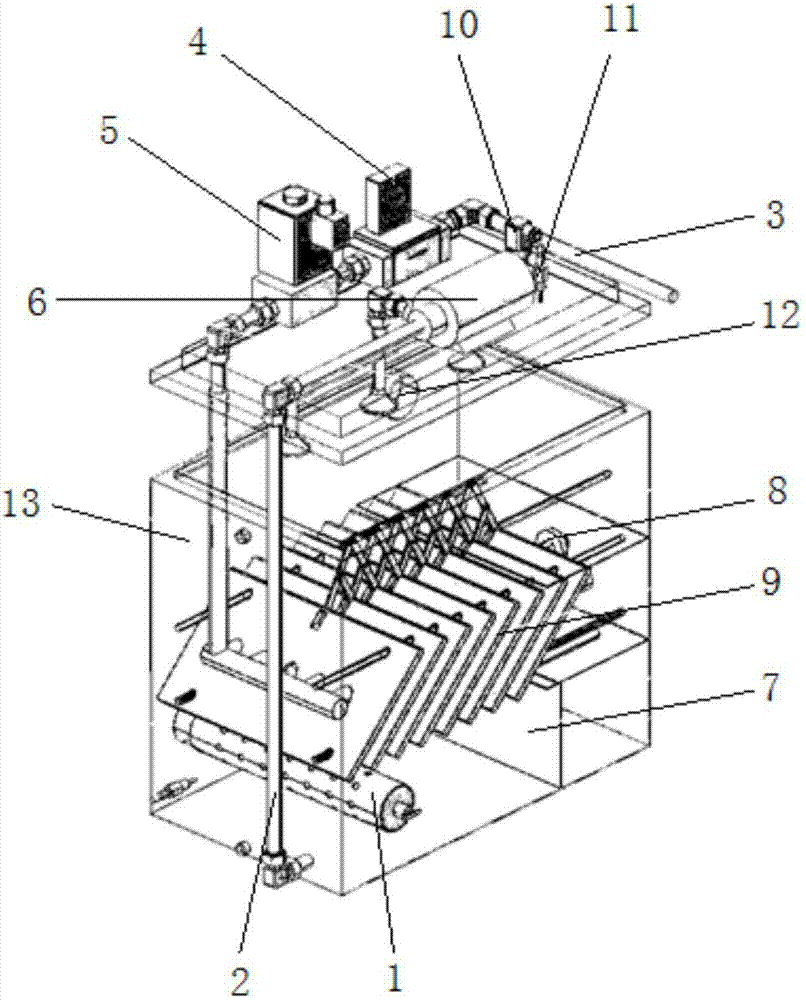

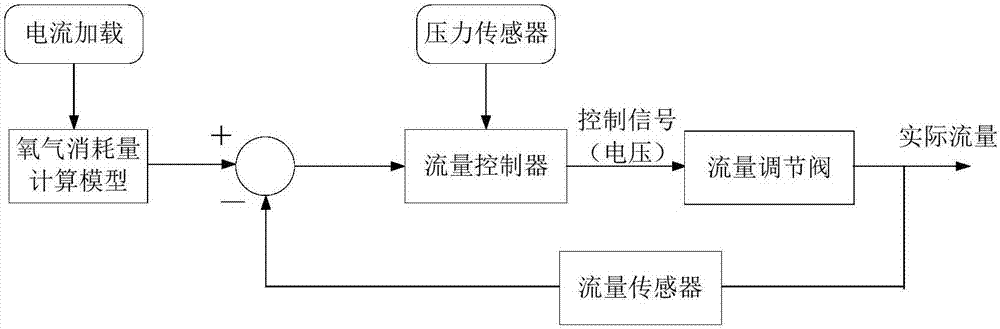

[0034] A stack cathode simulation test device for fuel cell air supply system, refer to figure 1 , figure 2 , including a housing 13, a circulating water circuit 2 for installing an electric water pump 6, an air intake pipe 1 for simulating the air intake of the stack, an air discharge port 12 for discharging excess air, and a cathode volume adjustment chamber 7 for adjusting the volume of air flowing through 1. A flow resistance regulator 9 for adjusting the pressure loss of air flowing through and an air consumption port 3 for simulating oxygen consumption. The front end of the air consumption port 3 is sequentially installed with an electric valve 5 and a flow sensor 4 connected to the control computer 0 . The air intake pipe 1 and the cathode volume adjustment chamber 7 are arranged at the bottom of the casing 13, the air discharge port 12 is arranged at the top of the casing 13, the flow resistance regulator 9 is arranged at the top of the cathode volume adjustment chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com