Numerical control machining simulation device based on triangular binary tree model

A simulation device and triangular technology, applied in simulators, general control systems, control/regulation systems, etc., can solve problems such as poor real-time performance and inability to achieve continuous parts processing, and achieve less overhead, increased speed, Effects of real-time part machining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings.

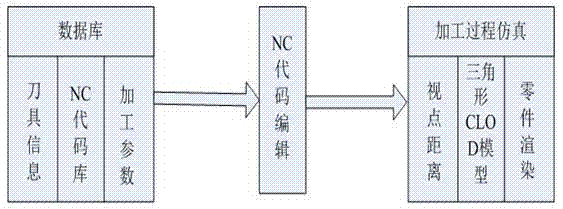

[0022] Such as figure 1 As shown, a NC machining simulation device based on a triangular binary tree model is composed of a database module, an NC code editor module, and a machining process simulation module.

[0023] The database module is connected with the NC code editor module through the serial interface, and the NC code editor module is connected with the process simulation module through the serial interface.

[0024] First, the tool information, NC code library, and processing parameters in the database are integrated to generate the NC code of the processed part;

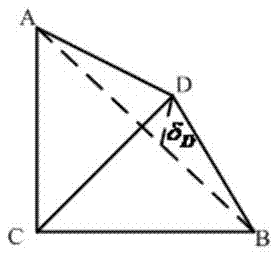

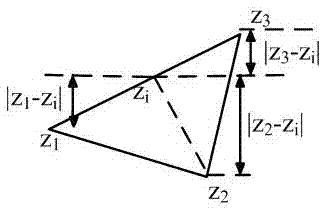

[0025] Secondly, determine the processing area under each NC code, and process parts according to different viewpoint distances and surface feature conditions of free-form surfaces, such as figure 2 As shown, the geometric error is used to determine whether the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com