Automatic modeling and hardware in-the-loop simulation method of contactor

A technology of automatic modeling and simulation methods, which is applied in design optimization/simulation, instruments, biological neural network models, etc., can solve problems such as poor versatility, large amount of calculation, and difficult to guarantee estimation accuracy, so as to facilitate development and promote application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

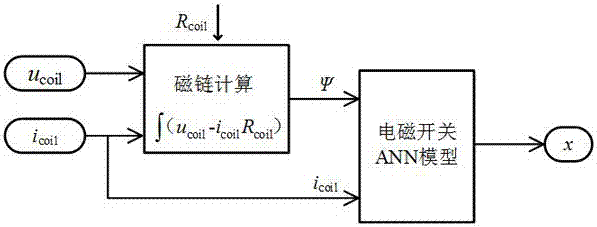

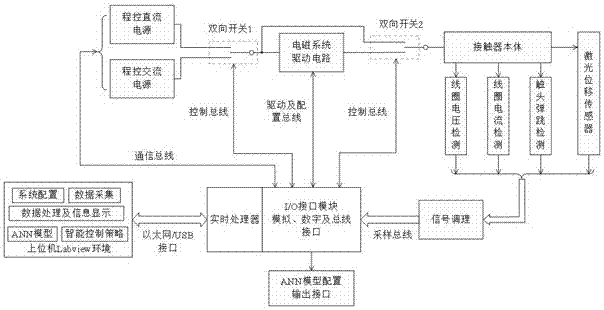

[0028] A method for automatic modeling and hardware-in-the-loop simulation of a contactor, comprising the following steps: S1: collecting dynamic operating parameters of the contactor, operating parameters coil voltage, coil current, iron core displacement, and contact bounce information; S2: using the collected The coil voltage, coil current and core displacement data are used to train the ANN model of the contactor; S3: Output accurate core displacement information according to the input coil voltage and coil current information, which is used to realize the intelligent control strategy based on the displacement closed loop; S4: Integrate into the contactor control system, download the intelligent control strategy and the ANN model of the contactor to the real-time processor, carry out the real-time operation of the control strategy and the AN...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com