Intelligent elastic casing pipe protecting sleeve and design method thereof

An intelligent elastic, protective sleeve technology, applied in casing, design optimization/simulation, calculation, etc., can solve the problem of difficult to repair the sealing state between layers, and achieve the effect of improving the service life and protecting the casing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

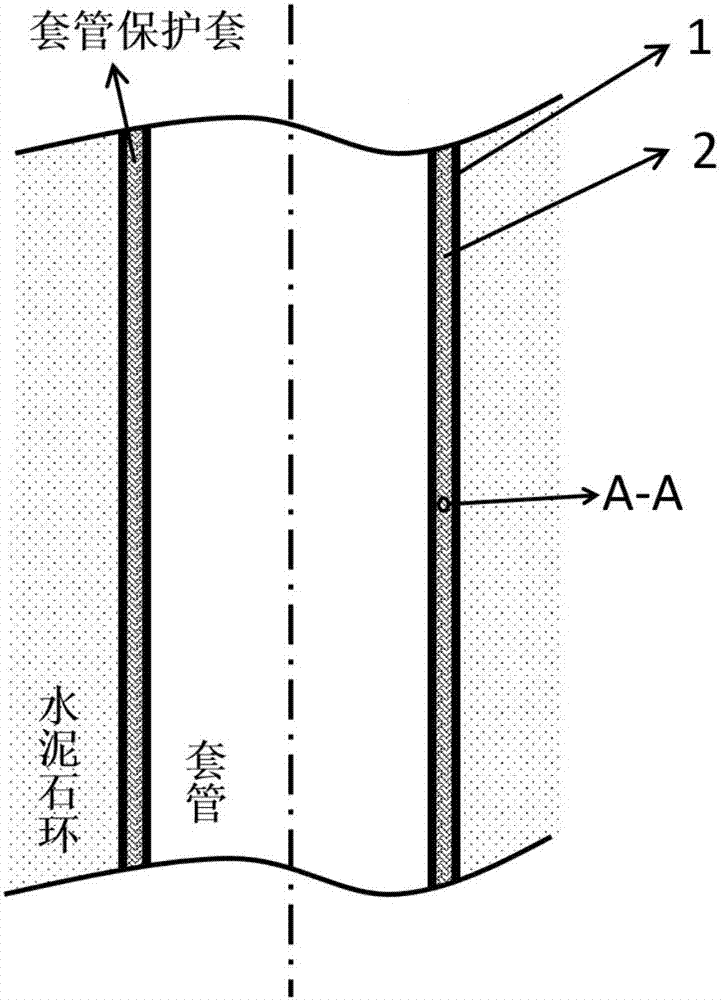

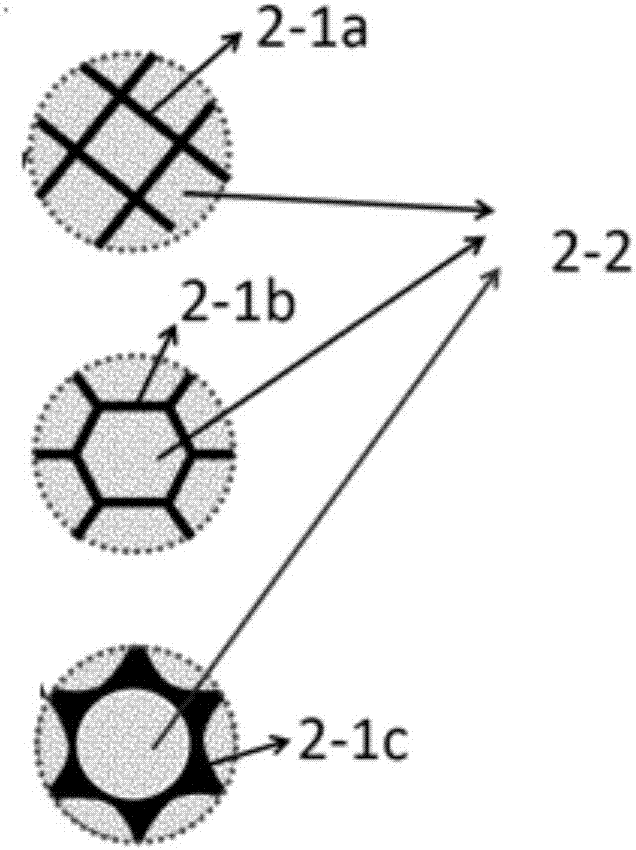

[0043] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

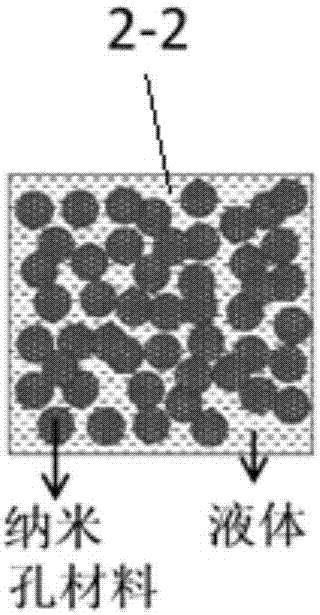

[0044] Such as figure 1 figure 2 image 3 As shown, an intelligent elastic sleeve protective cover includes a covering layer and an intelligent elastic layer. The cladding layer is made of medium-resistant and high-temperature-resistant nitrile rubber, which plays a primary protective role for the intelligent elastic layer; the intelligent elastic layer is composed of a mixture of nanoporous materials and liquid encapsulated by the main body skeleton. The main frame is made of nitrile rubber; it is composed of several hollow small volumes, which can be cube, honeycomb or cylindrical; the small volumes are connected but not connected: each small volume frame is connected to each other As a whole as the main skeleton; the cladding space in each small volume is independent of each other, so as to ensure that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com