LED package device and packaging method thereof

A technology for LED packaging and LED devices, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of unsolved packaging glue and easy falling off, and achieve the effects of improving luminous flux, simple packaging operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

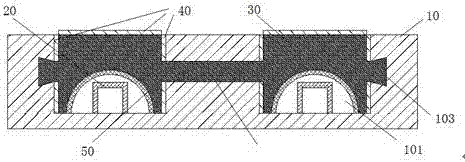

[0045] Such as figure 1 As shown, this embodiment provides an LED packaging device, including a substrate 10, a chip 20 and an encapsulation layer 30. There are two chips 20; the substrate 10 is provided with two mounting grooves 101, and the chip 20 is installed in the corresponding mounting groove 101 Inside, a through hole 102 is provided between adjacent mounting grooves 101; the packaging layer 30 fills the mounting groove 101 through the through hole 102, the packaging layer 30 covers the chip 20, and the upper surface of the packaging layer 30 is provided with a phosphor layer 40; the mounting groove 101 The side is provided with a groove 103, and the corresponding part of the packaging layer 30 is provided with a protrusion matching the shape of the groove 103; the groove 103 is a trapezoidal groove, and the upper surface of the trapezoidal groove is the opening end of the trapezoidal groove; the installation groove 101, the through hole 102 A reflection layer is provi...

Embodiment 2

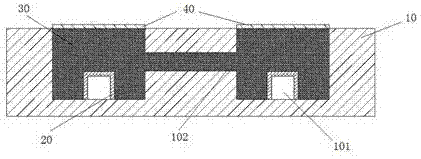

[0052] Such as figure 2 As shown, this embodiment provides an LED packaging device, including a substrate 10, a chip 20 and an encapsulation layer 30. There are two chips 20; the substrate 10 is provided with two mounting grooves 101, and the chip 20 is installed in the corresponding mounting groove 101 Inside, a through hole 102 is provided between adjacent mounting grooves 101 ; the encapsulation layer 30 fills the mounting groove 101 through the through hole 102 , the encapsulation layer 30 covers the chip 20 , and the upper surface of the encapsulation layer 30 is provided with a phosphor layer 40 .

Embodiment 3

[0054] This embodiment provides an LED packaging device, including a substrate 10, a chip 20 and an encapsulation layer 30. There are two chips 20; A through hole 102 is provided between the adjacent mounting grooves 101; the packaging layer 30 penetrates the through hole 102 and fills the mounting groove 101, the packaging layer 30 covers the chip 20, and the upper surface of the packaging layer 30 is provided with a phosphor layer 40; the inner wall of the mounting groove 101 is rough noodle.

[0055] The inner wall of the installation groove 101 is rough, and when the encapsulation layer 30 is solidified, the encapsulation glue can fully wet the rough inner wall of the installation groove 101, and the inner wall of the installation groove 101 has a larger contact area with the encapsulation layer 30, and the connection is stronger; in addition, the rough installation The inner wall of the groove 101 can generate a relatively large frictional force, thereby preventing relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com