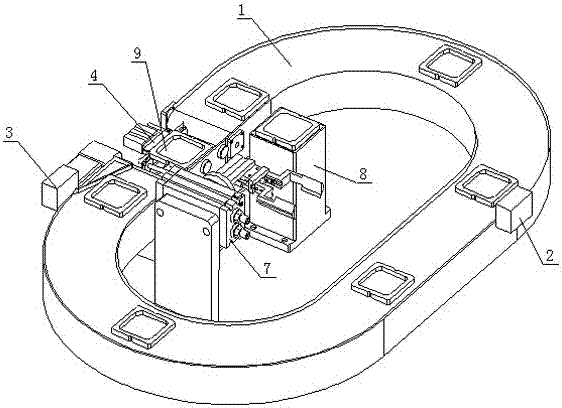

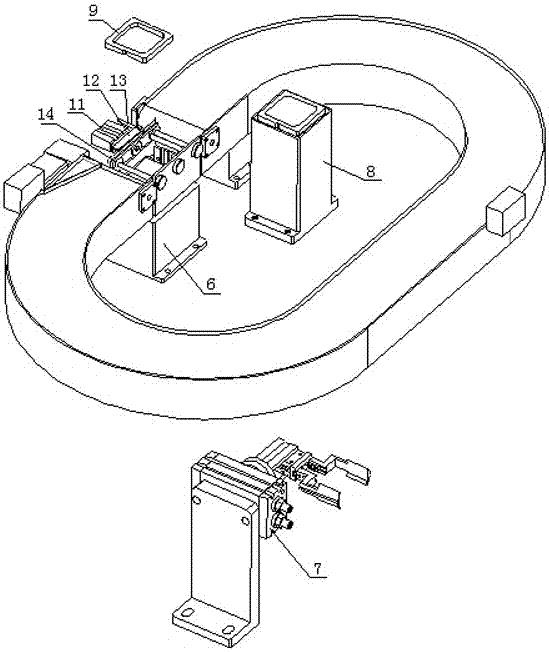

Bulk material feeding method and device for chip mounter

A feeding device and placement machine technology, which is applied in the direction of assembling printed circuits, printed circuits, electrical components, etc. with electrical components, can solve problems such as difficulties in the manual placement process, failure to meet production needs, long preparation time, etc., to avoid Re-taping process, ensuring the assembly process, and achieving the effect of batch placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The bulk material feeding method for chip mounter of the present invention, concrete steps comprise:

[0031] Step 1. Enter or program the basic information of all types of components to be mounted and the corresponding identification code information into the control center of the placement machine.

[0032] The basic information entered includes the type, model, polarity, shape and other information of components for later recall and comparison. Among them, in order to form a one-to-one relationship, after entering the basic information, it is necessary to register and save the corresponding identification code correspondingly, so as to provide convenience for later scanning the code to confirm the type of component.

[0033] Step 2. Paste the corresponding identification codes on the side walls of the material boxes, and place the material boxes on the endless conveyor belt for automatic transmission and feeding.

[0034] The pasted identification code can be pasted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com