A multi-stage extraction and concentration-free reconstituted tobacco preparation method and reconstituted tobacco leaves

A technology of reconstituted tobacco leaves and reconstituted tobacco, which is applied in the field of tobacco, can solve the problems affecting the quality of reconstituted tobacco leaves and the loss of aroma components in reconstituted tobacco leaves, and achieve the effects of reduced irritation, fine texture and clear aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

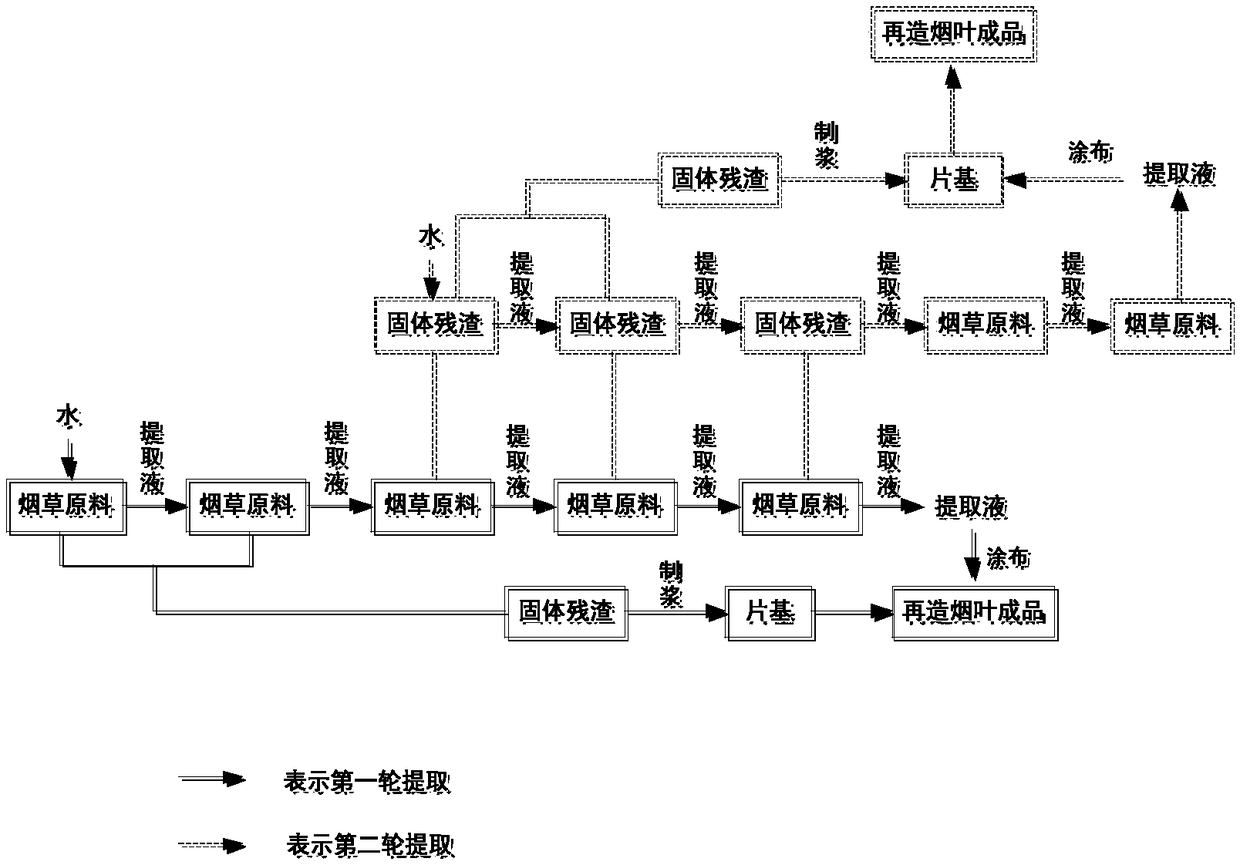

[0032] Such as figure 1 As shown, the present embodiment adopts two rounds of five-stage extraction:

[0033] (1) Take 5 portions of tobacco leaves, 100 grams each;

[0034] (2), the first round of five-level extraction:

[0035] A. Take the first tobacco leaf as raw material, water as solvent, extract at normal temperature with tobacco leaf: water mass ratio of 1:10 solid-liquid ratio, and then separate the solid and liquid by extrusion to obtain the first tobacco residue and For the first extract, the residual moisture is 75-80%;

[0036] B, using the second portion of tobacco leaves as a raw material, mixing the above two portions of extracts as a solvent, extracting at normal temperature, and then separating the solid and liquid by extrusion to obtain a second portion of residue and a second portion of extract;

[0037] C, using the third part of tobacco leaves as raw material, using the third part of the extract as a solvent, extracting at normal temperature, and then ...

Embodiment 2

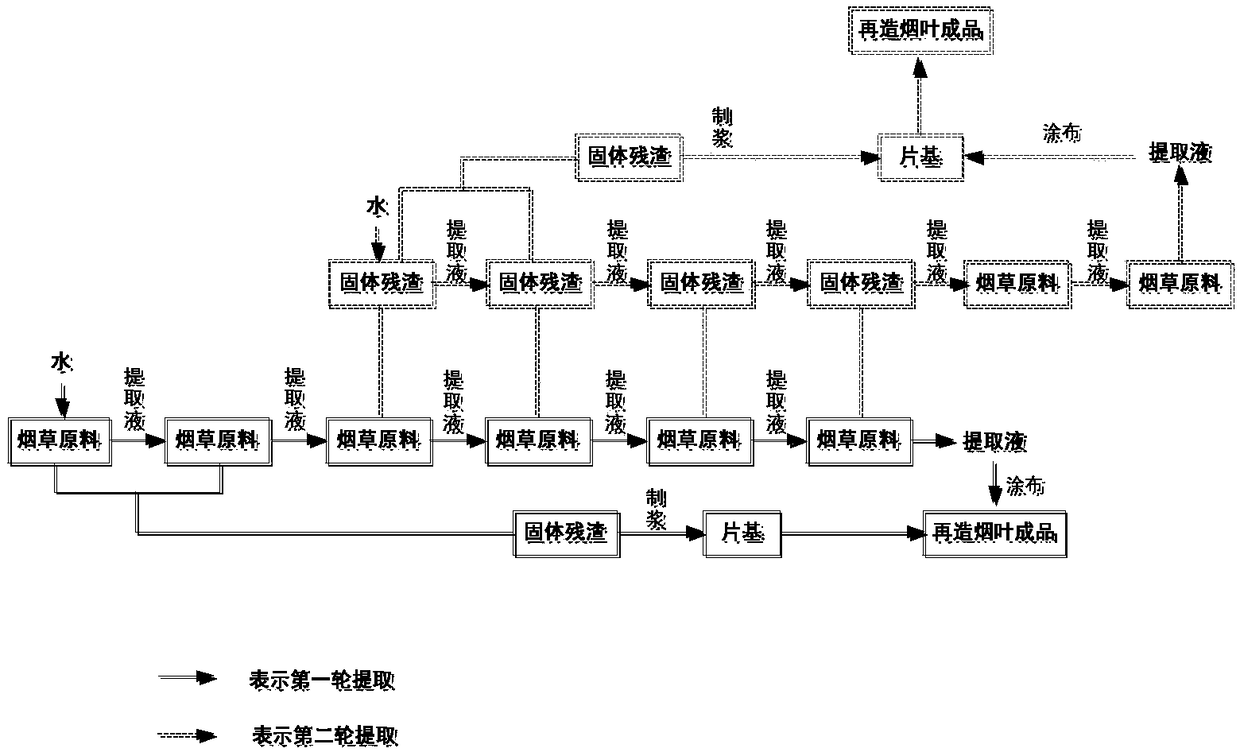

[0048] Such as figure 2 As shown, the present embodiment adopts two rounds of six-stage extraction:

[0049] (1) Take 6 portions of tobacco leaves, 100 grams each;

[0050] (2), the first round of six-level extraction:

[0051] A. Take the first tobacco leaf as raw material, water as solvent, extract at normal temperature with tobacco leaf: water mass ratio of 1:10 solid-liquid ratio, and then separate the solid and liquid by extrusion to obtain the first tobacco residue and For the first extract, the residual moisture is 75-80%;

[0052] B, using the second portion of tobacco leaves as a raw material, mixing the above two portions of extracts as a solvent, extracting at normal temperature, and then separating the solid and liquid by extrusion to obtain a second portion of residue and a second portion of extract;

[0053] C, using the third part of tobacco leaves as raw material, using the third part of the extract as a solvent, extracting at normal temperature, and then s...

Embodiment 3

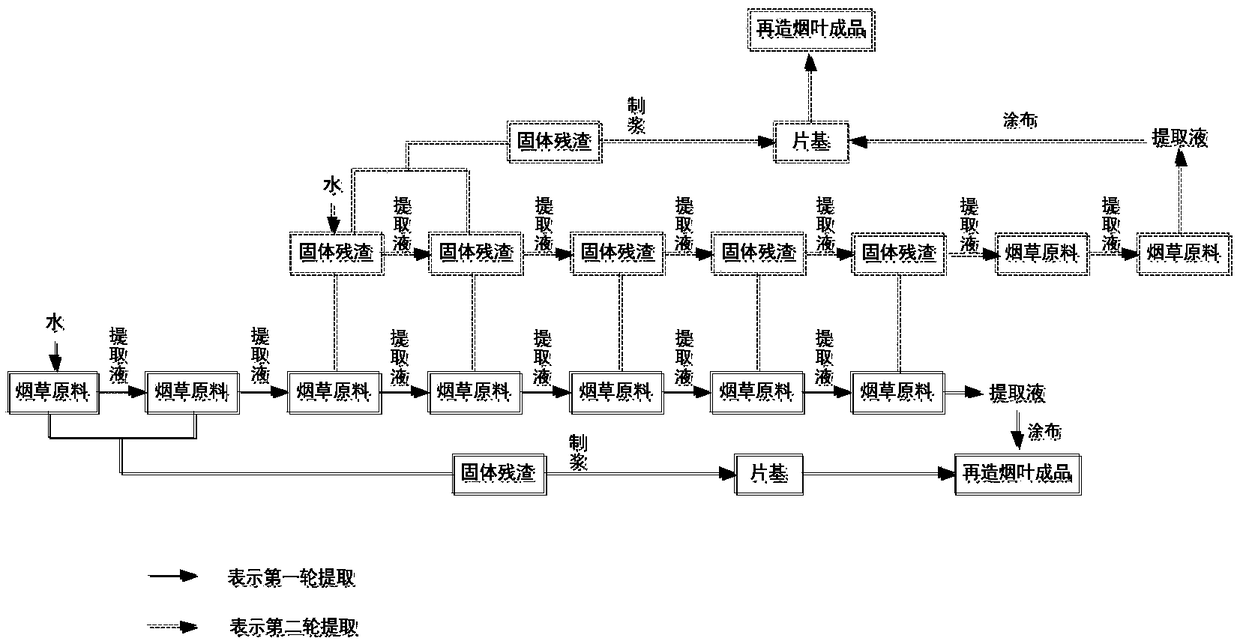

[0064] Such as image 3 As shown, the present embodiment adopts two rounds of seven-stage extraction:

[0065] (1), take 7 portions of tobacco leaves, each portion is 100 grams;

[0066] (2), the first round of seven-level extraction:

[0067] A. Take the first tobacco leaf as raw material, water as solvent, extract at normal temperature with tobacco leaf: water mass ratio of 1:10 solid-liquid ratio, and then separate the solid and liquid by extrusion to obtain the first tobacco residue and For the first extract, the residual moisture is 75-80%;

[0068] B, using the second portion of tobacco leaves as a raw material, mixing the above two portions of extracts as a solvent, extracting at normal temperature, and then separating the solid and liquid by extrusion to obtain a second portion of residue and a second portion of extract;

[0069] C, using the third part of tobacco leaves as raw material, using the third part of the extract as a solvent, extracting at normal temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com